Abstract

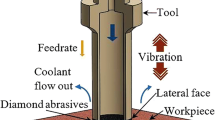

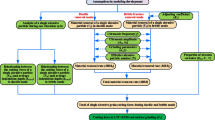

Rotary ultrasonic machining of brittle materials, such as glass, ceramics, silicon, and sapphire, has been explored in a large number of experimental and theoretical investigations. Mechanistic models have been developed to predict the material removal rate or cutting force in the rotary ultrasonic machining of brittle materials. However, most merely describe the rotary ultrasonic machining process of drilling holes in brittle materials. There are no reports on the development of a cutting force model for flat surface rotary ultrasonic machining, i.e., rotary ultrasonic face milling. This paper presents a mathematical model for the cutting force in the rotary ultrasonic face milling of brittle materials under the assumption that brittle fracture removal is the primary mode of material removal. Verification experiments are conducted for the developed cutting force model and show that the trends of input variables for the cutting force agree well with the trends of the developed cutting force model. The developed cutting force model can be applied to evaluate the cutting force in the rotary ultrasonic face milling of brittle materials.

Similar content being viewed by others

References

Arif M, Rahman M, Yoke San W (2011) Analytical model to determine the critical feed per edge for ductile–brittle transition in milling process of brittle materials. Int J Mach Tool Manuf 51(3):170–181

Pei ZJ, Ferreira PM, Haselkorn M (1995) Plastic flow in rotary ultrasonic machining of ceramics. J Mater Process Technol 48(1–4):771–777

Sayuti M, Sarhan Ahmed AD, Fadzil M, Hamdi M (2012) Enhancement and verification of a machined surface quality for glass milling operation using CBN grinding tool–Taguchi approach. Int J Adv Manuf Technol 60(9–12):939–950

Wan ZP, Tang Y (2009) Brittle–ductile mode cutting of glass based on controlling cracks initiation and propagation. Int J Adv Manuf Technol 43(11–12):1051–1059

Zhou M, Ngoi BKA, Yusoff MN, Wang XJ (2006) Tool wear and surface finish in diamond cutting of optical glass. J Mater Process Technol 174(1–3):29–33

Fang FZ, Chen LJ (2000) Ultra-precision cutting for ZKN7 glass. CIRP Ann Manuf Technol 49(1):17–20

Gu WB, Yao ZQ, Li HL (2011) Investigation of grinding modes in horizontal surface grinding of optical glass BK7. J Mater Process Technol 211(10):1629–1636

Chen ST, Jiang ZH, Wu YY, Yang HY (2011) Development of a grinding–drilling technique for holing optical grade glass. Int J Mach Tool Manuf 51(2):95–103

Belkhir N, Bouzid D, Herold V (2009) Surface behavior during abrasive grain action in the glass lapping process. Appl Surf Sci 255(18):7951–7958

Stephenson DJ, Sun X, Zervos C (2006) A study on ELID ultra precision grinding of optical glass with acoustic emission. Int J Mach Tool Manuf 46(10):1053–1063

Matsumura T, Muramatsu T, Fueki S (2011) Abrasive water jet machining of glass with stagnation effect. CIRP Ann Manuf Technol 60(1):355–358

Nath C, Lim GC, Zheng HY (2012) Influence of the material removal mechanisms on hole integrity in ultrasonic machining of structural ceramics. Ultrasonics 52(5):605–613

Kumar J, Khamba JS, Mohapatra SK (2009) Investigating and modeling tool-wear rate in the ultrasonic machining of titanium. Int J Adv Manuf Technol 41(11–12):1107–1117

Gan J, Wang X, Zhou M, Ngoi B, Zhong Z (2003) Ultraprecision diamond turning of glass with ultrasonic vibration. Int J Adv Manuf Technol 21(12):952–955

Liu K, Li XP, Rahman M, Liu XD (2004) Study of ductile mode cutting in grooving of tungsten carbide with and without ultrasonic vibration assistance. Int J Adv Manuf Technol 24(5–6):389–394

Liu K, Li XP, Rahman M (2008) Characteristics of ultrasonic vibration-assisted ductile mode cutting of tungsten carbide. Int J Adv Manuf Technol 35(7–8):833–841

Peng Y, Wu YB, Liang ZQ, Guo YB, Lin X (2011) An experimental study of ultrasonic vibration-assisted grinding of polysilicon using two-dimensional vertical workpiece vibration. Int J Adv Manuf Technol 54(9–12):941–947

Yan Y, Zhao B, Liu J (2009) Ultraprecision surface finishing of nano-ZrO2 ceramics using two-dimensional ultrasonic assisted grinding. Int J Adv Manuf Technol 43(5–6):462–467

Peng Y, Liang Z, Wu Y, Guo Y, Wang C (2012) Characteristics of chip generation by vertical elliptic ultrasonic vibration-assisted grinding of brittle materials. Int J Adv Manuf Technol 62(5–8):563–568

Shen XH, Zhang JH, Xing DL, Zhao YF (2012) A study of surface roughness variation in ultrasonic vibration-assisted milling. Int J Adv Manuf Technol 58(5–8):553–561

Shen XH, Zhang JH, Li H, Wang JJ, Wang XC (2012) Ultrasonic vibration-assisted milling of aluminum alloy. Int J Adv Manuf Technol 63(1–4):41–49

Pei ZJ, Prabhakar D, Ferreira PM, Haselkorn M (1995) Mechanistic approach to the prediction of material removal rates in rotary ultrasonic machining. J Eng Ind 117(2):142–151

Gong H, Fang FZ, Hu XT (2010) Kinematic view of tool life in rotary ultrasonic side milling of hard and brittle materials. Int J Mach Tool Manuf 50(3):303–307

Lv DX, Huang YH, Tang YJ, Wang HX (2012) Relationship between subsurface damage and surface roughness of glass BK7 in rotary ultrasonic machining and conventional grinding processes. International Journal of Advanced Manufacturing Technology. doi:10.1007/s00170-012-4509-1

Li ZC, Jiao Y, Deines TW, Pei ZJ, Treadwell C (2005) Rotary ultrasonic machining of ceramic matrix composites: feasibility study and designed experiments. Int J Mach Tool Manuf 45(12–13):1402–1411

Zhang CL, Feng PF, Zhang JF, Wu ZJ, Yu DW (2012) Investigation into the rotary ultrasonic face milling of K9 glass with mechanism study of material removal. Int J Manuf Technol Manag 25(4):248–266

Cong WL, Feng Q, Pei ZJ, Deines TW, Treadwell C (2012) Edge chipping in rotary ultrasonic machining of silicon. Int J Manuf Res 7(3):311–329

Zhang CL, Feng PF, Zhang JF (2013) Ultrasonic vibration-assisted scratch-induced characteristics of C-plane sapphire with a spherical indenter. Int J Mach Tool Manuf 64(1):38–48

Ya G, Qin HW, Yang SC, Xu YW (2002) Analysis of the rotary ultrasonic machining mechanism. J Mater Process Technol 129(1–3):182–185

Zhang QH, Wu CL, Sun JL, Jia ZX (2000) Mechanism of material removal in ultrasonic drilling of engineering ceramics. Proc Inst Mech Eng B J Eng Manuf 214(9):805–810

Liu DF, Cong WL, Pei ZJ, Tang YJ (2012) A cutting force model for rotary ultrasonic machining of brittle materials. Int J Mach Tool Manuf 52(1):77–84

Zhang CL, Feng PF, Wu ZJ, Yu DW (2011) Mathematical modeling and experimental research for cutting force in rotary ultrasonic drilling. Chin J Mech Eng 47(15):149–155

Singh R, Khamba JS (2009) Mathematical modeling of tool wear rate in ultrasonic machining of titanium. Int J Adv Manuf Technol 43(5–6):573–580

Kumar J, Khamba JS (2010) Modeling the material removal rate in ultrasonic machining of titanium using dimensional analysis. Int J Adv Manuf Technol 48(1–4):103–119

Pei ZJ, Ferreira PM, Kapoor SG, Haselkorn M (1995) Rotary ultrasonic machining for face milling of ceramics. Int J Mach Tool Manuf 35(7):1033–1046

Pei ZJ, Ferreira PM (1999) Experimental investigation of rotary ultrasonic face milling. Int J Mach Tool Manuf 39(8):327–1344

Turchetta S (2009) Cutting force on a diamond grit in stone machining. Int J Adv Manuf Technol 44(9–10):854–861

Patnaik Durgumahanti US, Singh V, Venkateswara Rao P (2010) A new model for grinding force prediction and analysis. Int J Mach Tool Manuf 50(3):231–240

Fang FZ, Zhang GX (2004) An experimental study of optical glass machining. Int J Adv Manuf Technol 23(3):155–160

Arif M, Rahman M, San W, Doshi N (2011) An experimental approach to study the capability of end-milling for microcutting of glass. Int J Adv Manuf Technol 53(9):1063–1073

Jiao F (2008) The Theoretical and experimental studies on ultrasonic aided high efficiency lapping with solid abrasive of engineering ceramic, Ph. D. thesis. Shanghai Jiao Tong University

Marshall DB, Lawn BR, Evans AG (1982) Elastic/plastic indentation damage in ceramics: the lateral crack system. J Am Ceram Soc 65(11):561–566

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, C., Zhang, J. & Feng, P. Mathematical model for cutting force in rotary ultrasonic face milling of brittle materials. Int J Adv Manuf Technol 69, 161–170 (2013). https://doi.org/10.1007/s00170-013-5004-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5004-z