Abstract

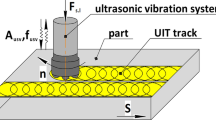

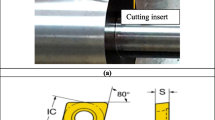

Titanium is known as the metal of the future because of its excellent combination of properties such as high specific strength, low thermal conductivity, and high corrosion resistance. There is a critical need for developing and establishing cost-effective methods for the machining of titanium, especially in terms of tool-wear optimization. This paper addresses the application of ultrasonic machining, an impact machining process for the cost-effective machining of commercially pure titanium (ASTM Grade-I) and evaluation of tool-wear rate under the effect of different process parameters. Tool material, abrasive material, slurry concentration, abrasive grit size, and power rating of the ultrasonic machine were included as the input factors in this investigation. The optimal settings of these parameters were determined through experiments planned, conducted, and analyzed using the Taguchi method. The significant parameters contributing most to the variation in tool-wear rate were identified and the results obtained were validated by conducting the confirmation experiments. Thereafter, the outcome of the Taguchi model has been used for developing a micro-model for tool-wear rate (TWR); using Buckingham’s pie theorem. A comparison of the experimental results obtained assists in the validation of the model.

Similar content being viewed by others

References

Thoe TB, Aspinwall DK, Wise MLH (1998) Review on ultrasonic machining. Int J Mach Tools Manuf 38(4):239–255

Benedict GF (1987) Non-traditional manufacturing processes. Marcel Dekker, Inc., New York, pp 67–86

Singh R, Khamba JS, Grewal JS (2005) Machining characteristics optimization using Taguchi technique in ultrasonic drilling of titanium alloys. Proceedings of international conference on emerging technologies in intelligent system and control (EISCO-2005). Kumaraguru College of Tech. Coimbatore, India, pp 81–87

Singh R, Khamba JS (2005) Development in USM for drilling of titanium alloys. Proceedings of the national conference on advances in condensed matter physics (ACMP-05). Thapar University, Patiala (India), pp 333–339

Adithan M (1981) Tool wear characteristics in ultrasonic drilling. Tribol Int 14(6):351–356

Smith TL (1971) Parametric influence in ultrasonic machining. Dissertation of B.Sc., Nottingham Trent University, UK, pp 23–32

Adithan M, Vanktesh VC (1974) Parametric influence on tool wear in ultrasonic drilling. Tribol Int 7(6):260–264

Riddie V (1973) Cavitation erosion—a survey of the literature 1940–1970. Wear 23:133–137

Adithan M, Vanktesh VC (1976) Production accuracy of holes in ultrasonic drilling. Wear 40(3):309–318

Komaraiah M, Reddy PN (1993) Relative performance of tool materials in ultrasonic machining. Wear 161(1/2):1–10

Komaraiah M, Reddy PN (1991) Rotary ultrasonic machining-a new cutting process and its performance. Int J Prod Res 29(11):2177–2187

Soundrajan V, Radhakrishnan V (1986) An experimental investigation on the basic mechanisms involved in the ultrasonic machining. Int J Mach Tool Des Res 26(3):307–321

Ross PJ, Taguchi (1988) Taguchi technique for quality engineering. McGraw-Hill Book Company, New York, pp 45–48

Barker TB (1990) Engineering quality by design: Interpreting the Taguchi approach. Marcel-Dekker, Inc., New York, pp 78–82

Gilmore R (1991) Ultrasonic machining—a case study. J Mater Process Technol 28:139–143

Kennedy DC, Grieve RJ (1975) Ultrasonic machining: a review. Prod Eng 54(9):481–486

Moreland MA (1988) Versatile performance of ultrasonic machining. Ceram Bull 67(6):1045–1047

Jadoun RS et al (2006) Manufacturing process optimization for tool wear rate in ultrasonic drilling of engineering ceramics using the Taguchi method. Int J Mach Machinabil Mater 1:94–114

Smith TJ (1973) Parameter influences in ultrasonic machining. Tribol Int 11(5):196–198

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, J., Khamba, J.S. & Mohapatra, S.K. Investigating and modeling tool-wear rate in the ultrasonic machining of titanium. Int J Adv Manuf Technol 41, 1107–1117 (2009). https://doi.org/10.1007/s00170-008-1556-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1556-8