Abstract

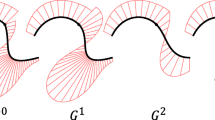

In this paper, a modeling approach is presented in order to evaluate feed rate during a circular interpolation in high-speed milling. The developed model depends on the type of discontinuity and the kinematic performance of the machine tool. To begin with, a feed rate modeling for circular interpolation with continuity in tangency is developed. After, the discontinuity in tangency between two circular interpolations is replaced by discontinuity in curvature by adding a fillet which is in relation to the functional tolerance ε imposed in the part design. An experimental study has been carried out to validate the models.

Similar content being viewed by others

References

Siller H, Rodriguez CA, Ahuett H (2006) Cycle time prediction in high-speed milling operations for sculptured surface finishing. J Mater Process Technol 174:355–362

Souza AF, Coelho RT (2007) Experimental investigation of feed rate limitations on high speed milling aimed at industrial applications, Int J Adv Manuf Technol doi:10.1007/s00170-006-0445-2

Sinumerik (2006) 840Dsl/840Disl/840D/840Di/810D Manuel de programmation Notions de base

Pateloup V (2005) Amélioration du comportement cinématique des machines outils UGV—Application au calcul de trajets d’évidement de poches, Phd thesis, Blaise Pascal–Clermont II University

Dugas A (2002) Simulation d’usinage de formes complexes, Phd thesis, IRCCYN, Ecole Centrale Nantes

Pessoles X (2010) Aide au choix du posage en usinage 5 axes continus par la modélisation du comportement cinématique des machines—outils, Phd thesis, Université Toulouse 3 Paul Sabatier (UT3 Paul Sabatier)

Tapie L, Mawussi BK, Anselmetti B (2007) Circular tests for HSM machine tools: bore machining application. Int J Mach Tool Manuf 47:805–819

Moneral M, Rodriguez CA (2003) Influence of tool path strategy on the cycle time of high-speed milling. Comput-Aided Des 35:395–401

Coelho RT, Souza AF, Rodrigues Roger A, Yoshida Rigatti AM, Ribeiro AL (2009) Mechanistic approach to predict real machining time for milling free-form geometries applying high feed rate, Int J Adv Manuf Technol, doi:10.1007/s00170-009-2183-8

Zhao ZY, Wang CY, Zhou HM, Qin Z (2007) Pocketing tool path optimization for sharp corners. J Mater Process Technol 192–193:175–180

Pateloup V, Duc E, Ray P (2004) Corner optimization for pocket machining. Int J Mach Tool Manuf 44:1343–1353

Held M, Spielberger CH (2009) A smooth spiral tool path for high speed machining of 2D pockets. Comput-Aided Des 41:539–550

Sai L, Bouzid W, Zghal A (2008) Chip thickness analysis for different tool motions for adaptive feed rate. J Mater Process Technol 204:213–220

Kloypayan J, Lee YS (2002) Material engagement analysis of different end mills for adaptive feed rate control in milling process. Comput Ind 47:55–76

Erkorkmaz K, Altintas Y (2001) High speed CNC system design. Part I: jerk limited trajectory generation and quintic spline interpolation. Int J Mach Tool Manuf 41:1323–1345

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gassara, B., Baili, M., Dessein, G. et al. Feed rate modeling in circular–circular interpolation discontinuity for high-speed milling. Int J Adv Manuf Technol 65, 1619–1634 (2013). https://doi.org/10.1007/s00170-012-4284-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4284-z