Abstract

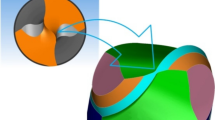

The development trend of modern engineering production is manifested by automation and mechanization based on the widespread use of CNC machining centers. The use of such centres in a multirange production mode ensures implementation of functionally linked technological transitions (operations) for processing the vast majority of the surfaces of a workpiece during a single installation, in compliance with the principle of unity of bases, which provides for achieving higher processing accuracy. In modern engineering, one of the most labor-intensive operations is the processing of holes, which are subject to high technological requirements for accuracy in size, shape, and location. CNC machining centers offer the option of using various milling strategies to produce high-precision holes. Such strategies are a circular interpolation strategy and a screw interpolation strategy. In this paper, we consider the main factors affecting the accuracy of the shape of the holes obtained by milling using a circular interpolation strategy. Mathematical models have been developed for calculating the magnitude of the shape error associated with the process of instrument penetration into the workpiece material and the elastic deformation of the tool during the final treatment.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Leonov SL (2012) Modelirovanie protsessa frezerovaniia otverstii na stankakh s ChPU (Modeling the process of milling holes on CNC machines). Polzunovskii Vestnik 1(1):177–180

Stel’makov VA (2017) Modelirovanie protsessa formoobrazovaniia tsilindricheskikh otverstii poluchennykh metodom frezerovaniia na stankakh s ChPU (Modeling the process of forming cylindrical holes obtained by milling on CNC machines). Electronic Scientific Edition “Uchenye zametki TOGU” 8(2):321–327. https://pnu.edu.ru/media/ejournal/articles-2017/TGU_8_159.pdf

Stel’makov VA (2015) Issledovanie prichin vozniknoveniia pogreshnostei formy pri obrabotke otverstii frezerovaniem (Investigation the causes mold errors when machining holes by milling). Problems and achievements in innovative materials and technologies of mechanical engineering: materials of the International scientific and technical conference, pp 257–259

Davydov VM, Kabaldin IuG (2003) Kontseptual’noe proektirovanie mekhatronnykh modulei mekhanoobrabotki (Conceptual design of mechatronic machining modules). Dal’nauka Publ., Vladivostok, p 251

Stel'makov VA (2016) Metod otsenki tochnosti gladkikh tsilindricheskikh otverstii po diametral'nomu razmeru i otnositel'nomu polozheniiu ikh osei (Method for assessing the accuracy smooth cylindrical holes by the diametric size and relative position their axes). Uchenye zapiski Komsomol’skogo-na-Amure gosudarstvennogo tekhnicheskogo universiteta. Nauki o prirode i tekhnike, I-1(25):73–81

Kabaldin IuG (2000) Matematicheskoe modelirovanie samoorganizuiushchikhsia protsessov v tekhnologicheskikh sistemakh obrabotki rezaniem (Mathematical modeling self-organizing processes in cutting systems). Dal'nauka Publ., Vladivostok, p 195

Dunin-Barkovskii IV Kartashova AN (1978) Izmereniia i analiz sherokhovatosti, volnistosti i nekruglosti poverkhnosti (Measurements and analysis surface roughness, waviness and non-circularity). Mashinostroenie Publ., Moscow, p 232

Uaitkhauz D (2009) Metrologiia poverkhnostei. Printsipy, promyshlennye metody i pribory (Surfaces metrology. Principles, industrial methods and devices). Dolgoprudny, “Intellekt” Publ., p 472

Stel’makov VA (2016) Poluchenie zadannykh parametrov sherokhovatosti pri sverlenii i frezerovanii tsilindricheskikh otverstii (Obtaining the specified roughness parameters during drilling and milling cylindrical holes). Uchenye zapiski Komsomol’skogo-na-Amure gosudarstvennogo tekhnicheskogo universiteta. Nauki o prirode i tekhnike I-1 (25):66–72

Stel’makov VA (2015) Issledovanie vliianiia rezhimov obrabotki na tochnost’ formy otverstii, poluchennykh frezerovaniem (Study the influence processing modes on the accuracy the shape of the holes obtained by milling). Informatsionnye tekhnologii XXI veka, pp 50–55

Stel’makov VA (2015) Issledovanie prichin vozniknoveniia pogreshnostei formy pri obrabotke otverstii frezerovaniem (Investigation the causes mold errors when machining holes by milling). Problems and achievements in innovative materials and technologies of mech. eng.: materials of the International scientific and technical conference, pp 257–259

Kim C-J (2004) Mechanisms of chip formation and cutting dynamics in the micro-scale milling process. Dissertation, University of Michigan, p 111

Downs RA (1993) Surface topography measurement using fringe-field capacitive profilometry. Dissertation, University of Washington, p 136

Lou S, Jiang X, Scott Paul J (2014) Morphological filters for functional assessment of roundness profiles. Meas Sci Technol 25(6):1–16

Tokyo Seimitsu Co. Ltd. (2006) Application guide manual for roundness and cylindrical profile measuring instrument. Tokyo, p 96

Altintas Y, Engin S (2001) Generalized modeling of mechanics and dynamics of milling cutters. Ann CIRP 50(1):25–30

Kountanya RK (2002) Process mechanics of metal cutting with edge radiused and worn tools. Dissertation, The University of Michigan, Ann Arbor

Rahman M, Kumar AS, Prakash JRS (2001) Micro milling of pure copper. J Mater Proc Tech 116:39–43

Chuzhoy L, DeVor RE, Kapoor SG, Bammann DJ (2002) Microstructure-level modeling of ductile iron machining. ASME J Manuf Sci Eng 124:162–169

Kitahara T, Ishikawa Y, Terada T, Nakajima N, Furuta K (1996) Development of micro-lathe. Mech Eng Lab Rep 50(5):117–123

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Editor(s) (if applicable) and The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Stelmakov, V.A., Gimadeev, M.R., Iakuba, D.D. (2021). Research on the Process of Forming Cylindrical Surfaces of Holes During Milling Finish with End Mills Using a Circular Interpolation Strategy. In: Radionov, A.A., Gasiyarov, V.R. (eds) Proceedings of the 6th International Conference on Industrial Engineering (ICIE 2020). ICIE 2021. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-54817-9_106

Download citation

DOI: https://doi.org/10.1007/978-3-030-54817-9_106

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-54816-2

Online ISBN: 978-3-030-54817-9

eBook Packages: EngineeringEngineering (R0)