Abstract

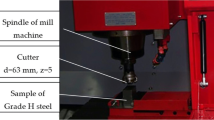

In machining fixtures, minimizing workpiece deformation due to clamping and cutting forces is essential to maintain the machining accuracy. This can be achieved by selecting the optimal location of fixturing elements such as locators and clamps. Many researches in the past decades described more efficient algorithms for fixture layout optimization. In this paper, artificial neural networks (ANN)-based algorithm with design of experiments (DOE) is proposed to design an optimum fixture layout in order to reduce the maximum elastic deformation of the workpiece caused by the clamping and machining forces acting on the workpiece while machining. Finite element method (FEM) is used to find out the maximum deformation of the workpiece for various fixture layouts. ANN is used as an optimization tool to find the optimal location of the locators and clamps. To train the ANN, sufficient sets of input and output are fed to the ANN system. The input includes the position of the locators and clamps. The output includes the maximum deformation of the workpiece for the corresponding fixture layout under the machining condition. In the testing phase, the ANN results are compared with the FEM results. After the testing process, the trained ANN is used to predict the maximum deformation for the possible fixture layouts. DOE is introduced as another optimization tool to find the solution region for all design variables to minimum deformation of the work piece. The maximum deformations of all possible fixture layouts within the solution region are predicted by ANN. Finally, the layout which shows the minimum deformation is selected as optimal fixture layout.

Similar content being viewed by others

References

Menassa RJ, DeVries WR (1991) Optimization methods applied to selecting support positions in fixture design. ASME J Eng Ind 113:412–418

Kashyap S, DeVries WR (1999) Finite element analysis and optimization in fixture design. Struct Optim 18:193–201

Li B, Melkote SN (1999) Improved workpiece location accuracy through fixture layout optimization. Int J Mach Tool Manuf 39:871–883

Liu S-G, Zheng L, Zhang Z-H, Li Z-Z, Liu D-C (2007) Optimization of the number and positions of fixture locators in the peripheral milling of a low-rigidity workpiece. Int J Adv Manuf Technol 33:668–676

Shaogang Liu L, Zheng L, Zhang ZH, Wen DH (2005) Optimal fixture design in peripheral milling of thin-walled workpiece. Int J Adv Manuf Technol 28:653–658

Qin GH, Zhang WH, Wan M (2006) A mathematical approach to analysis and optimal design of a fixture locating scheme. Int J Adv Manuf Technol 29:349–359

S’anchez HT, Estrems M, Faura F (2006) Analysis and compensation of positional and deformation errorsusing integrated fixturing analysis in flexible machining parts. Int J Adv Manuf Technol 29:239–252

Kulankara K, Satyanarayana S, Melkote SN (2002) Iterative fixture layout and clamping force optimization using the genetic algorithm. ASME J Manuf Sci Eng 124:119–125

Kaya N (2006) Machining fixture locating and clamping position optimization using genetic algorithms. Comput Ind 57:112–120

Prabhakaran G, Padmanaban KP, Krishnakumar R (2007) Machining fixture layout optimization using FEM and evolutionary techniques. Int J Adv Manuf Technol 32:1090–1103

Padmanaban KP, Arulshri KP, Prabhakaran G (2009) Machining fixture layout design using ant colony algorithm based continuous optimization method. Int J Adv Manuf Technol 45:922–934

Chen W, Ni L, Xue J (2008) Deformation control through fixture layout design and clamping force optimization. Int J Adv Manuf Technol 38:860–867

Padmanaban KP, Prabhakaran G (2008) Dynamic analysis on optimal placement of fixturing elements using evolutionary techniques. Int J Prod Res 46(15):4177–4214

Yildiz AR, Ozturk F (2006) Hybrid enhanced genetic algorithm to select optimal machining parameters in turning operation. J Eng Manuf 220(12):2041–2053

Yildiz AR (2009) A new design optimization framework based on immune algorithm and taguchi method. Comput Ind 60(8):613–620

Yildiz AR, Ozturk N, Kaya N, Ozturk F (2007) Hybrid multi-objective shape design optimization using taguchi's method and genetic algorithm. Struct Multidiscip Optim 34(4):277–365

Amaral N, Rencis JJ, Rong YK (2005) Development of a finite element analysis tool for fixture design integrity verification and optimization. Int J Adv Manuf Technol 25:409–419

Yildiz R, Saitou K (2011) Topology synthesis of multicomponent structural assemblies in continuum domains. Trans ASME, J Mech Des 133(1):011008-1–011008-9

Yildiz AR (2009) A novel particle swarm optimization approach for product design and manufacturing. Int J Adv Manuf Technol 40(5–6):617–628

Yildiz AR (2008) Hybrid Taguchi-harmony search algorithm for solving engineering optimization problems. Int J Ind Eng Theory Appl Pract 15(3):286–293

Yildiz AR (2009) A novel hybrid immune algorithm for global optimization in design and manufacturing. Robot Comput Integr Manuf 25(2):261–270

Yildiz AR (2009) An effective hybrid immune-hill climbing optimization approach for solving design and manufacturing optimization problems in industry. J Mater Process Technol 50(4):224–228

Yildiz AR (2009) Hybrid immune-simulated annealing algorithm for optimal design and manufacturing. Int J Mater Prod Technol 34(3):217–226

Hamedi M (2005) Intelligent fixture design through a hybrid system of artificial neural network and genetic algorithm. Artif Intell Rev 23:295–311

Ozan S, Taskin M, Kolukisa S, Ozerdem MS (2008) Application of ANN in the prediction of the pore concentration of aluminum metal foams manufacturedby powder metallurgy methods. Int J Adv Manuf Technol 39:251–256

Panneerselvam K, Aravindan S, Noorul Haq A (2009) Hybrid of ANN with genetic algorithm for optimization of frictional vibration joining process of plastics. Int J Adv Manuf Technol 42:669–677

Yildiz AR, Ozturk N, Kaya N, Ozturk F (2003) Integrated optimal topology design and shape optimization using neural networks. Struct Multidiscip Optim 25(4):251–260

Kaya N, Ozturk F (2003) The application of chip removal and frictional contact analysis for workpiece–fixture layout verification. Int J Adv Manuf Technol 21:411–419

Li B, Melkote SN (2001) Fixture clamping force optimisation and its impact on workpiece location accuracy. Int J Adv Manuf Technol 17:104–113

Hornik K, Stinchcombe M, White H (1989) Multilayer feedforward networks are universal approximators. Neural Netw 2:359–366

Siebenaler SP, Melkote SN (2005) Prediction of workpiece deformation in a fixture system using the finite element method. Int J Mach Tools Manuf 46:51–58

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Selvakumar, S., Arulshri, K.P., Padmanaban, K.P. et al. Design and optimization of machining fixture layout using ANN and DOE. Int J Adv Manuf Technol 65, 1573–1586 (2013). https://doi.org/10.1007/s00170-012-4281-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4281-2