Abstract

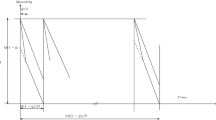

In this paper, we develop an integrated inventory model for vendor–buyer coordination under an imperfect production process. The proportion of defective items in each production lot is assumed to be stochastic and follows a known probability density function. The vendor inspects the items while they are being produced and delivers good-quality items to the buyer in small lots over multiple shipments. We assume that shortages are permitted and are completely backordered. The expected annual integrated total cost is derived and a solution procedure is provided to find the optimal solution. Numerical examples show that the integrated model gives an impressive cost reduction in comparison to an independent decision by the buyer. The results also show that if back orders are permitted, the expected integrated annual cost is less than that when back orders are not permitted. Therefore, if customers are willing to wait for the next shipment when a shortage occurs, it is profitable for the company to allow back orders although the delay incurs a penalty cost.

Similar content being viewed by others

References

Cao M, Zhang Q (2010) Supply chain collaborative advantage: a firm's perspective. Int J Prod Econ 128(1):358–367

Goyal SK (1976) An integrated inventory model for a single supplier-single customer problem. Int J Prod Res 15(1):107–111

Banerjee A (1986) A joint economic-lot-size model for purchaser and vendor. Decis Sci 17(3):292–311

Goyal SK (1988) A joint economic-lot-size model for purchaser and vendor: a comment. Decis Sci 19(1):236–241

Goyal SK, Gupta YP (1989) Integrated inventory models: the buyer-vendor coordination. Eur J Oper Res 41(3):261–269

Aderohunmu R, Mobolurin A, Bryson N (1995) Joint vendor–buyer policy in JIT manufacturing. J Oper Res Soc 46(3):375–385

Lu L (1995) A one-vendor multi-buyer integrated inventory model. Eur J Oper Res 81(2):312–323

Goyal SK (1995) A one-vendor multi-buyer integrated inventory model: a comment. Eur J Oper Res 82(1):209–210

Hill RM (1997) The single-vendor single-buyer integrated production-inventory model with a generalized policy. Eur J Oper Res 97(3):493–499

Ha D, Kim SL (1997) Implementation of JIT purchasing: an integrated approach. Prod Plann Contr 8(2):152–157

Viswanathan S (1998) Optimal strategy for the integrated vendor–buyer inventory model. Eur J Oper Res 105(1):38–42

Hill RM (1999) The optimal production and shipment policy for the single-vendor single-buyer integrated production—inventory model. Int J Prod Res 37(11):2463–2475

Hoque MA, Goyal SK (2000) An optimal policy for a single-vendor single-buyer integrated production-inventory system with capacity constraint of the transport equipment. Int J Prod Econ 65(3):305–315

Goyal SK, Szendrovits AZ (1986) A constant lot size model with equal and unequal size batch shipments between production stages. Eng Cost Prod Econ 10:203–210

Goyal SK, Nebebe F (2000) Determination of economic production-shipment policy for a single-vendor single-buyer system. Eur J Oper Res 121(1):175–178

Yang PC, Wee HM (2000) Economic ordering policy of deteriorated item for vendor and buyer: an integrated approach. Prod Plann Contr 11(5):474–480

Wu KS, Ouyang LY (2003) An integrated single-vendor single-buyer inventory system with shortage derived algebraically. Prod Plann Contr 14(6):555–561

Ouyang LY, Wu KS, Ho CH (2004) Integrated vendor–buyer cooperative models with stochastic demand in controllable lead time. Int J Prod Econ 92(3):255–266

Hsiao J, Lin C (2005) A buyer-vendor EOQ model with changeable lead-time in supply chain. Int J Adv Manuf Technol 26:917–921

Chang HC, Ouyang LY, Wu KS, Ho CH (2006) Integrated vendor–buyer cooperative inventory models with controllable lead time and ordering cost reduction. Eur J Oper Res 170(2):481–495

Hill RM, Omar M (2006) Another look at the single-vendor single-buyer integrated production inventory problem. Int J Prod Res 44(4):791–800

Hoque MA, Goyal SK (2006) A heuristic solution procedure for an integrated inventory system under controllable lead-time with equal or unequal sized batch shipments between a vendor and a buyer. Int J Prod Econ 102(2):217–225

Sarmah SP, Acharya D, Goyal SK (2006) Buyer vendor coordination models in supply chain management. Eur J Oper Res 175(1):1–15

Siajadi H, Ibrahim R, Lochert P (2006) A single-vendor multiple-buyer inventory model with a multiple-shipment policy. Int J Adv Manuf Tech 27:1030–1037

Chan C, Kingsman B (2007) Coordination in a single-vendor multi-buyer supply chain by synchronizing delivery and production cycles. Transport Res E 43(2):90–111

Ertogral K, Darwish M, Ben-Daya M (2007) Production and shipment lot sizing in a vendor–buyer supply chain with transportation cost. Eur J Oper Res 176(3):1592–1606

Zhou Y, Wang S (2007) Optimal production and shipment models for a single-vendor-single-buyer integrated system. Eur J Oper Res 180(1):309–328

Ben-Daya M, Darwish M, Ertogral K (2008) The joint economic lot sizing problem: review and extensions. Eur J Oper Res 185(2):726–742

Chung KJ (2008) An improvement of an integrated single-vendor single-buyer inventory model with shortage. Prod Plann Contr 19(3):275–277

Ben-Daya M, Al-Nassar A (2008) An integrated inventory production system in a three-layer supply chain. Prod Plann Contr 19(2):97–104

Huang CK, Tsai DM, Wu JC, Chung KJ (2010) An integrated vendor–buyer inventory model with order-processing cost reduction and permissible delay in payments. Eur J Oper Res 202(2):473–478

Huang CK, Tsai DM, Wu JC, Chung KJ (2010) An optimal integrated vendor–buyer inventory policy under conditions of order-processing time reduction and permissible delay in payments. Int J Prod Econ 128(1):445–451

Porteus EL (1986) Optimal lot sizing, process quality improvement and setup cost reduction. Oper Res 34(1):137–144

Lee HL, Rosenblatt MJ (1987) Simultaneous determination of production cycles and inspection schedules in a production system. Manag Sci 33:1125–1137

Schwaller RL (1988) EOQ under inspection costs. Prod Invent Manag 29(3):22–24

Ben-Daya M, Hariga M (2000) Economic lot scheduling problem with imperfect production processes. J Oper Res Soc 51:875–881

Salameh MK, Jaber MY (2000) Economic production quantity model for items with imperfect quality. Int J Prod Econ 64(1):59–64

Huang CK (2002) An integrated vendor–buyer cooperative inventory model for items with imperfect quality. Prod Plann Contr 13(4):355–361

Goyal SK, Huang CK, Chen KC (2003) A simple integrated production policy of an imperfect item for vendor and buyer. Prod Plann Contr 14(7):596–602

Goyal SK, Cárdenas-Barrón LE (2002) Note on: economic production quantity model for items with imperfect quality—a practical approach. Int J Prod Econ 77(1):85–87

Huang CK (2004) An optimal policy for a single-vendor single-buyer integrated production-inventory problem with process unreliability consideration. Int J Prod Econ 91(1):91–98

Lo ST, Wee HM, Huang WC (2007) An integrated production-inventory model with imperfect production processes and Weibull distribution deterioration under inflation. Int J Prod Econ 106(1):248–260

Yoo SH, Kim D, Park MS (2009) Economic production quantity model with imperfect-quality items, two-way imperfect inspection and sales return. Int J Prod Econ 121(1):255–265

Cárdenas-Barrón LE (2009) Economic production quantity with rework process at a single-stage manufacturing system with planned backorders. Comput Ind Eng 57(3):1105–1113

Sana SS (2010) An economic production lot size model in an imperfect production system. Eur J Oper Res 201(1):158–170

Chung KJ (2011) The economic production quantity with rework process in supply chain management. Comput Math Appl 62(6):2547–2550

Khan M, Jaber MY, Maurice B (2011) An economic order quantity (EOQ) for items with imperfect quality and inspection errors. Int J Prod Econ 133(1):113–118

Raouf A, Jain JK, Sathe PT (1983) A cost-minimization model for multicharacteristic component inspection. IIE Trans 15(3):187–194

Hsu LF (2012) A note on “An economic order quantity (EOQ) for items with imperfect quality and inspection errors”. Int J Ind Eng Comput 3(4):695–702

Khan M, Jaber MY, Guiffrida AL, Zolfaghari S (2011) A review of the extensions of a modified EOQ model for imperfect quality items. Int J Prod Econ 132(1):1–12

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hsu, JT., Hsu, LF. An integrated vendor–buyer cooperative inventory model in an imperfect production process with shortage backordering. Int J Adv Manuf Technol 65, 493–505 (2013). https://doi.org/10.1007/s00170-012-4188-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4188-y