Abstract

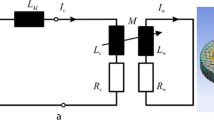

Electromagnetic forming (EMF) process is a high-speed forming process which can inhibit warping, reduce springback, and improve the formability of material at room temperature. In general, the electromagnetic forming process is applied to high-conductive metals such as copper, aluminum, and their alloys. In order to solve the problem of the low formability of titanium alloy, the electromagnetic forming process can be applied to form titanium alloy. The effects on the forming properties of titanium and other low-conductive metals must be studied before the EMF process is used. To that end, this paper presents a tool: a 3D numerical simulation method of electromagnetic forming with a driver. First, the electromagnetic field distribution and electromagnetic forces are calculated using the ANSYS/EMAG software. The resulting data are then imported to ABAQUS/Explicit software to carry out mechanical analysis. Although the electromagnetic field calculation does not take the deformation of the blank into account, the results accurately reflect the law of the deformation. This method is especially suitable for cases involving small deformations, such as tube compression and embossing. The calculation can also be used to simulate the impact forming process between the driver and the blank.

Similar content being viewed by others

References

Daehn GS, Vohnout VJ, DuBois L (1999) Improved formability with electromagnetic forming: fundamentals and a practical example. Minerals, Metals and Materials Society/AIME, Warrendale

Seth M, Vohnout VJ, Daehn GS (2005) Formability of steel sheet in high velocity impact. J Mater Process Technol 168(3):390–400. doi:10.1016/j.jmatprotec.2004.08.032

El-Azab A, Garnich M, Kapoor A (2003) Modeling of the electromagnetic forming of sheet metals: state-of-the-art and future needs. J Mater Process Technol 142(3):744–754. doi:10.1016/s0924-0136(03)00615-0

Takatsu N, Kato M, Sato K, Tobe T (1988) High-speed forming of metal sheets by electromagnetic force. Jpn Soc Mech Eng Int J 31(1):142–148

Fenton GK, Daehn GS (1998) Modeling of electromagnetically formed sheet metal. J Mater Process Technol 75(1–3):6–16. doi:10.1016/s0924-0136(97)00287-2

Oliveira DA, Worswick MJ, Finn M, Newman D (2005) Electromagnetic forming of aluminum alloy sheet: free-form and cavity fill experiments and model. J Mater Process Technol 170(1–2):350–362. doi:10.1016/j.jmatprotec.2005.04.118

Yu H, Li C, Deng J (2009) Sequential coupling simulation for electromagnetic–mechanical tube compression by finite element analysis. J Mater Process Technol 209(2):707–713. doi:10.1016/j.jmatprotec.2008.02.061

Cui X, Mo J, Han F (2012) 3D Multi-physics field simulation of electromagnetic tube forming. Int J Adv Manuf Technol 59(5):521–529. doi:10.1007/s00170-011-3540-y

Svendsen B, Chanda T (2005) Continuum thermodynamic formulation of models for electromagnetic thermoinelastic solids with application in electromagnetic metal forming. Continuum Mech Therm 17(1):1–16. doi:10.1007/s00161-004-0181-5

Unger J, Stiemer M, Schwarze M, Svendsen B, Blum H, Reese S (2008) Strategies for 3D simulation of electromagnetic forming processes. J Mater Process Technol 199(1–3):341–362. doi:10.1016/j.jmatprotec.2007.08.028

Stiemer M, Unger J, Svendsen B, Blum H (2009) An arbitrary Lagrangian Eulerian approach to the three-dimensional simulation of electromagnetic forming. Comput Meth Appl M 198(17–20):1535–1547. doi:10.1016/j.cma.2009.01.014

Takahashi M, Murakoshi Y, Terasaki M, Sano T, Matsuno KI (1988) Study on electromagnetic forming. V. Free bulging of high-strength-metal plates. II. J Mech Eng Lab (Jpn) 42(1):1–8

Shin C, Jin H, Lee J, Lee D-J, Rhee C-K, Hong J-H (2008) Expansion of a low conductive metal tube by an electromagnetic forming process: finite element modeling. Met Mater Int 14(1):91–97. doi:10.3365/met.mat.2008.02.091

Zhang P (2003) Joining enabled by high velocity deformation. The Ohio State University, Columbus

Srinivasan S (2010) A simulation perspective on dimensional control and formability in impact forming. Ohio State University, Columbus

Imbert JM, Winkler SL, Worswick MJ, Oliveira DA, Golovashchenko S (2005) The effect of tool–sheet interaction on damage evolution in electromagnetic forming of aluminum alloy sheet. J Eng Mater Technol 127(1):145–153

Correia JPM, Siddiqui MA, Ahzi S, Belouettar S, Davies R (2008) A simple model to simulate electromagnetic sheet free bulging process. Int J Mech Sci 50(10–11):1466–1475. doi:10.1016/j.ijmecsci.2008.08.008

Manea TE, Verweij MD, Blok H (2002) The importance of velocity term in the electromagnetic forming process. Proceedings of 27th General Assembly of the International Union of Radio Science, URSI, Maastricht, pp 112–115

Beley V, Ferrtik SM, Khimenko LT (1996) Electromagnetic metal forming handbook, English version of Russian book translated by Altynova MM. Ohio State University

Kuo CL, You JS, Hwang SF (2011) Temperature effect on electromagnetic forming process by finite element analysis [J]. Int J Appl Electromagn Mech 35:25–37

Wang Y, Xia Y (2003) Modeling of mechanical behavior of brass at high strain rates. J Mater Sci Lett 22(20):1393–1394. doi:10.1023/a:1025738825378

Meyers MA (1994) Dynamic behavior of materials. Wiley, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, F., Mo, J., Zhou, H. et al. 3D Numerical simulation method of electromagnetic forming for low conductive metals with a driver. Int J Adv Manuf Technol 64, 1575–1585 (2013). https://doi.org/10.1007/s00170-012-4124-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4124-1