Abstract

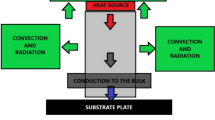

This paper presents a simple and efficient method for the analysis of dynamic behavior of the workpiece in the electromagnetic forming process. A two-dimensional (2D) axisymmetric finite element model with the equations of electrical equivalent circuit, electromagnetic field, and mechanical field has been developed for calculating the discharge currents through the forming coil, the magnetic forces acting on the workpiece, and the plastic deformation of the workpiece. By considering the effects of the sheet geometry and velocity on the above parameters, the method realizes the full coupling between the electromagnetic fields and the workpiece deformation, which should be more accurate than the existing loose coupling and sequential coupling simulation methods.

Similar content being viewed by others

References

Psyk V, Risch D, Kinsey BL, Tekkaya AE, Kleiner M (2011) Electromagnetic forming—a review. J Mater Process Technol 211:787–829. doi:10.1016/j.jmatprotec.2010.12.012

Takatsu N, Kato M, Sato K, Tobe T (1988) High-speed forming of metal sheets by electromagnetic force. Jpn Soc Mech Eng Int J 31(1):142–147

Fenton GK, Daehn GS (1998) Modeling of electromagnetically formed sheet metal. J Mater Process Technol 75:6–16. doi:10.1016/S0924-0136(97)00287-2

Meriched A, Feliachi M, Mohellebi H (2000) Electromagnetic forming of thin metal sheets. IEEE Trans Magn 36(4):1808–1811. doi:10.1109/20.877796

Oliveira DA, Worswick MJ, Finn M, Newman D (2005) Electromagnetic forming of aluminum alloy sheet: free-form and cavity fill experiments and model. J Mater Process Technol 170:350–362. doi:10.1016/j.jmatprotec.2005.04.118

Correia JPM, Siddiqui MA, Ahzi S, Belouettar S, Davies R (2008) A simple model to simulate electromagnetic sheet free bulging process. Int J Mech Sci 50:1466–1475. doi:10.1016/j.ijmecsci.2008.08.008

Xu JR, Yu HP, Li CF (2013) Effects of process parameters on electromagnetic forming of AZ31 magnesium alloy sheets at room temperature. Int J Adv Manuf Technol 66(9–12):1591–1602. doi:10.1007/s00170-012-4442-3

Yu HP, Li CF, Deng JH (2009) Sequential coupling simulation for electromagnetic mechanical tube compression by finite element analysis. J Mater Process Technol 209:707–713. doi:10.1016/j.jmatprotec.2008.02.061

Wang L, Chen ZY, Li CX, Huang SY (2006) Numerical simulation of the electromagnetic sheet metal bulging process. Int J Adv Manuf Technol 30(5–6):395–400. doi:10.1007/s00170-005-0094-x

Cui XH, Mo JH, Xiao SJ, Du EH, Zhao J (2011) Numerical simulation of electromagnetic sheet bulging based on FEM. Int J Adv Manuf Technol 57:127–134. doi:10.1007/s00170-011-3273-y

Li FQ, Mo JH, Zhou HY, Fang Y (2013) 3D Numerical simulation method of electromagnetic forming for low conductive metals with a driver. Int J Adv Manuf Technol 64:1575–1585. doi:10.1007/s00170-012-4124-1

Manea TE, Verweij MD, Blok H (2002) The importance of the velocity term in the electromagnetic forming process. Proceedings of 27th general assembly of the international union of radio science, URSI, Maastricht, pp 112–115

Kuo CL, You JS, Hwang SF (2011) Temperature effect on electromagnetic forming process by finite element analysis. Int J Appl Electromagn Mech 35:25–37. doi:10.3233/JAE-2011-1319

Ravaud R, Lemarquand G, Lemarquand V (2010) Mutual inductance and force exerted between thick coils. Prog Electromagn Res 102:367–380. doi:10.2528/PIER10012806

Xu D, Liu XS, Fang K, Fang HY (2010) Calculation of electromagnetic force in electromagnetic forming process of metal sheet. J Appl Phys 107:124907. doi:10.1063/1.3437201

Babic S, Sirois F, Akyel C, Lemarquand G, Lemarquand V, Ravaud R (2011) New formulas for mutual inductance and axial magnetic force between a thin wall solenoid and a thick circular coil of rectangular cross-section. IEEE Trans Magn 47(8):2034–2044. doi:10.1109/TMAG.2011.2125796

Lee SH, Lee DN (1994) A finite element analysis of electromagnetic forming for tube expansion. J Mater Process Technol 116(2):250–254. doi:10.1115/1.2904281

Cui XH, Mo JH, Li JJ, Huang L, Zhu Y, Li ZW, Zhong K (2013) Effect of second current pulse and different algorithms on simulation accuracy for electromagnetic sheet forming. Int J Adv Manuf Technol 68:1137–1146. doi:10.1007/s00170-013-4906-0

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cao, Q., Li, L., Lai, Z. et al. Dynamic analysis of electromagnetic sheet metal forming process using finite element method. Int J Adv Manuf Technol 74, 361–368 (2014). https://doi.org/10.1007/s00170-014-5939-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5939-8