Abstract

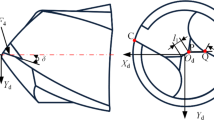

Drill with helical geometry drill point was developed to avoid the disadvantages of planar drill. For the visualization design and optimization of helical drill, a numerical modeling and simulation CAD system has been developed based on the mathematical models of helical drill. The characteristics of helical drill, such as lip clearance angle along cutting lip, heel clearance angle along flank surface, cutting edge inclination angle, rake angle, and so on, are described. Therefore, drill geometric parameters are modified reasonably according to different drilling requirements by the aid of the developed CAD simulation system. Besides, grinding parameters are obtained to guide the flank grinding process of helical drill. A case has been given to demonstrate the function of the system. And the calculated grinding parameters in the above case have been applied on a five-axis CNC grinding machine RollomΛtic 620XS with an assistant fixture to accomplish the flank grinding process. Drill geometry of ground drill shows good agreement with the simulative one, which validates the accuracy of proposed model method and relative CAD system.

Similar content being viewed by others

References

Lin C, Kang SK, Ehmann KF (1992) Planar micro-drill point design and grinding methods. Trans NAMRI/SME XX:173–179

Wile D (1989) Requirements for PCB: small-hole drilling machines. Electron Manuf 17:12–14

Kang SK (1993) Micro-drill geometry and grinding. Northwestern University, Evanston

Lin C, Kang SK, Ehmann KF (1995) Helical micro-drill point design and grinding. J Eng Ind 117:277–287

Chyan HC, Ehmann KF (1998) Development of curved helical micro-drill point technology for micro-hole drilling. Mechatronics 8:337–358

Chyan HC (1997) Curved helical drill technology for micro-hole drilling. Northwestern University, Evanston

Kang SK, Lin C, Ehmann KF (1993) Comparative analysis of planar and helical micro-drill points. Trans NAMRI/SME XXI:189–196

Zhou ZX, Yuan JJ, Lin C (1999) Mathematical model for non-coaxial helical micro-drill point. J Hunan Univ 26(3):30–34

Zhou ZX, Luo XY, Lin C (2001) Solutions to angles of non-coaxial helical micro-drill point. J Hunan Univ 28(3):32–36

Zhou ZX (2000) A kind of new micro-drill and grinding technology. Hunan University, Changsha

Paul A, Kapoor SG, DeVor DE (2005) Chisel edge and cutting lip shape optimization for improved twist drill point design. Int J Mach Tools Manuf 45:421–431

Dornfeld DA, Kim JS, Dechow H, Hewson J, Chen LJ (1999) Drilling burr formation in titanium alloy, Ti-6AI-4V. CIRP Ann Manuf Technol 48:73–76

Ganglani S, Ehmann KF (2001) Design and implementation of a helical drill point grinder. Trans NAMRI/SME XX|X:1–8

Hsieh JF (2005) Mathematical model for helical drill point. Int J Mach Tool Manuf 45:967–977

Hsieh JF (2006) Mathematical model and sensitivity analysis for helical groove machining. Int J Mach Tools Manuf 46:1087–1096

Hsieh JF, Lin PD (2005) Drill point geometry of multi-flute drills. Int J Adv Manuf Technol 26:466–476

Zhou ZX, Yuan JJ, Lin C (2000) Mathematical model and its CAD approach for flute machining of micro-drill. China Mech Eng 11(11):1284–1288

Zhou ZX, Yan L, Cao ZZ (2006) Development of the micro-drill CAD system and the model on the basis of the system. J Hunan Univ 33(2):36–39

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yan, L., Jiang, F. A practical optimization design of helical geometry drill point and its grinding process. Int J Adv Manuf Technol 64, 1387–1394 (2013). https://doi.org/10.1007/s00170-012-4109-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4109-0