Abstract

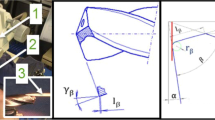

To investigate the influence of the geometric structure of coated cemented carbide twist drills on the drill tool life, drilling experiments of 42CrMo steel were carried out at various cutting parameters. The geometric structure parameters of the specially manufactured drill bits were designed by the multifactor orthogonal experiment method. The effects of cutting edge preparation, drill point geometry, and flute geometry on the tool wear were investigated by the range analysis and variance analysis. And their effects on chip pattern were also studied. Then the influence of cutting parameters on the tool life was investigated. Based on these investigations and extending the tool life, the optimized geometric structure was the honed cutting edge with a radius of 0.06 mm and conventional conical flank, and the corresponding cutting parameters were 80 m/min and 0.18 mm/rev. At last, the tool wear characteristics were discussed and the main wear mechanisms were abrasive wear, adhesive wear, coating exfoliation, and tipping.

Similar content being viewed by others

References

Ai X (2003) High speed machining technology. National Defence Industry Press, Beijing

Bagci E, Ozcelik B (2005) Analysis of temperature changes on the twist drill under different drilling conditions based on Taguchi method during dry drilling of Al 7075-T651. Int J Adv Manuf Technol 29:629–636

Bagci E, Ozcelik B (2006) Effects of different cooling conditions on twist drill temperature. Int J Adv Manuf Technol 34:867–877

Bagci E, Ozcelik B (2005) Finite element and experimental investigation of temperature changes on a twist drill in sequential dry drilling. Int J Adv Manuf Technol 28:680–687

Lin TR, Shyu RF (2000) Improvement of tool life and exit burr using variable feeds when drilling stainless steel with coated drills. Int J Adv Manuf Technol 16:308–313

Lin TR (2002) Cutting behaviour using variable feed and variable speed when drilling stainless steel with TiN-coated carbide drills. Int J Adv Manuf Technol 19:629–636

Tsao CC (2006) Prediction of thrust force of step drill in drilling composite material by Taguchi method and radial basis function network. Int J Adv Manuf Technol 36:11–18

Akhavan Farid A, Sharif S, Idris MH (2011) Chip morphology study in high speed drilling of Al–Si alloy. Int J Adv Manuf Technol 57:555–564

Paul A, Kapoor SG, DeVor RE (2005) Chisel edge and cutting lip shape optimization for improved twist drill point design. Int J Mach Tools Manuf 45:421–431

Chen W (1996) Design optimization of a split-point drill by force analysis. J Mater Process Technol 58:314–322

Liu C, Ai X, Liu Z, Wan Y (2009) Wear mechanism of cemented carbide tool in high speed machining iron-based superalloy GH2132. Trans Chin Soc Agric Mach 40:240–244

Liu Z, Ai X (2001) Investigation of wear lifespan of cutting tools in high speed machining. Tool Eng 35:3–7

Liu Z, Ai X (2002) Wear characteristics of cutting tools in high speed machining. Tribology 22:468–471

Zhang H, Deng J, Li G (2010) Effects of WC grain size on friction and wear behavior of WC cemented carbide tool material. Tool Eng 54:21–23

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, X., Huang, C., Zou, B. et al. Effects of geometric structure of twist drill bits and cutting condition on tool life in drilling 42CrMo ultrahigh-strength steel. Int J Adv Manuf Technol 64, 41–47 (2013). https://doi.org/10.1007/s00170-012-4026-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4026-2