Abstract

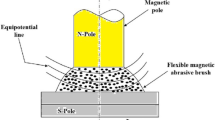

Recent needs to superfinished surfaces have motivated researchers to study on modern methods of polishing. Magnetic-assisted finishing is one of those methods which can generate mirror-like finished surfaces. This paper investigates the effects of some parameters, i.e., rotational speed of the permanent magnetic pole, working gap between the permanent pole and the workpiece, number of cycles, and the weight of the abrasive particles on aluminum surface finishing. Three-level full factorial method was used as design of experiments technique to study the selected factors. A total of 54 designed tests were done on aluminum sheet using an innovative material removal mechanism. Analysis of variance was used to determine significant factors and also to obtain an equation based on data regression. Experimental results indicate that the number of cycles and working gap are the most significant parameters on surface roughness change (∆Ra), followed by rotational speed and then weight of powder.

Similar content being viewed by others

References

Chang G-W (2003) Study on finishing characteristics of magnetic abrasive finishing and electrolytic magnetic abrasive finishing. Doctoral dissertation, Taiwan

Wang Y, Dejin Hu (2005) Study on the inner surface finishing of tubing by magnetic abrasive finishing. Int J Mach Tool Manuf 45:43–49

Yamaguchi H, Shinmura T, Sekine M (2005) Uniform internal finishing of SUS304 stainless steel bent tube using a magnetic abrasive finishing process. J Manuf Sci Eng 127:605–611

Jain VK, Prashant Kumar PK, Behera SCJayswal (2001) Effect of working gap and circumferential speed on the performance of magnetic abrasive finishing process. Wear 250:384–390

Mori T, Hirota K, Kawashima Y (2003) Clarification of magnetic abrasive finishing mechanism. J Mater Process Technol 143–144:682–686

Singh DK, Jain VK, Raghuram V (2005) On the performance analysis of flexible magnetic abrasive brush. Machining Science and Technology Journal 9:601–619

Jayswal SC, Jain VK, Dixit PM (2004) Analysis of magnetic abrasive finishing with slotted magnetic pole. NUMIFORM 2004. Proceedings of the 8th International Conference on Numerical Methods in Industrial Forming Processes. AIP Conference Proceedings 712:1435–1440

Singh DK, Jain VK, Raghuram V (2004) Parametric study of magnetic abrasive finishing process. J Mater Process Technol 149:22–29

Singh DK, Jain VK, Raghuram V, Komanduri R (2005) Analysis of surface texture generated by a flexible magnetic abrasive brush. Wear 259:1254–1261

Girma B, Joshi SS, Raghuram MVGS, Balasubramaniam R (2006) An experimental analysis of magnetic abrasives finishing of plane surfaces. Mach Sci Technol 10:323–340

Shinmura T, Takazawa K, Hatano E, Matsunaga M (1990) Study on magnetic abrasive finishing. Annals of the CIRP 39(1):325–328

Chang G, Yan B, Hsu R (2002) Study on cylindrical magnetic abrasive finishing using unbounded magnetic abrasives. Int J Mach Tool Manuf 42:575–583

M.J.Haddad, A. Fadaei Tehrani, A. Mohammadi, (2008) Statistical analysis of the influence of EDM parameters on surface roughness and roundness in cylindrical wire electrical discharge turning process. The International Conference on Advances in Materials and Processing Technologies (AMPT), Manama, Kingdom of Bahrain

Montgomery DC (2000) Design and analysis of experiments. Wiley, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Givi, M., Fadaei Tehrani, A. & Mohammadi, A. Polishing of the aluminum sheets with magnetic abrasive finishing method. Int J Adv Manuf Technol 61, 989–998 (2012). https://doi.org/10.1007/s00170-011-3753-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3753-0