Abstract

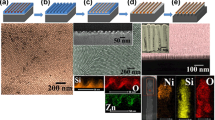

In this paper, adhesion between a metallic mask and a substrate is studied for further improvement of nano plastic forming and etching (NPFE), a nanofabrication process developed recently by the authors, in terms of the minimum pitch that can be achieved by this process. Control parameters of sputter deposition process, i.e., mask thickness, gas pressure, and ion current were studied for their influence on the adhesion. Silicon wafer was used as the substrate, and gold (Au) was used as the mask. First, the influence of the mask thickness on the adhesion was investigated, and the proper thickness was determined. Then, the influence of gas pressure on the adhesion was investigated, and the optimum gas pressure, in order to achieve the minimum pitch, was determined. Finally, the influence of ion current on the adhesion was investigated, and the optimum ion current was determined. Array of 20-nm-wide trenches with a periodicity of 120 nm were fabricated on silicon wafer using the improved nano plastic forming and etching. This improvement demonstrates the capability of NPFE for fabricating densely packed nanostructures with ultra-fine feature size and extremely high resolution.

Similar content being viewed by others

References

Brunner TA (2003) Why optical lithography lives forever. J Vac Sci Technol B 21:2632–2637

Mordechai R et al (2003) Recent trends in optical lithography. Linc Lab J 14:221–236

Fischer BP, Chou SY (1993) 10 nm electron beam lithography and Sub-50 nm overlay using a modified electron scanning microscope. Appl Phys Lett 62:2989–2991

Tseng AA, Chen K, Chen CD, Ma KJ (2003) Electron beam lithography in nanoscale fablication: recent developments. IEEE Trans Electron Packaging Manuf 62(2):141–149

Huigao D, Donald W, Joel KWY, Bryan MC, Vitor RM, Karl KB (2010) Sub-10-nm half-pitch electron-beam lithography by using poly(methylmethacrylate) as a negative resist. J Vac Sci Technol B 28(6):C6C58–C6C62

Wu B, Kumar A (2007) Extreme ultraviolet lithography: a review. J Vac Sci Technol B 25(6):1743–1761

Flanders DC (1980) Replication of 175-Å lines and spaces in polymethylmethacrylate using x-ray lithography. Appl Phys Lett 36:93–96

Hawryluk AM, Seppala LG (1988) Soft x-ray projection lithography using an x-ray reduction camera. J Vac Sci Technol B 6:2162–2166

Early K, Schattenburg ML, Smith HI (1990) Absence of resolution degradation in x-ray lithography for λ from 4.5 nm to 0.83 nm. Microelectron Eng 11:317–321

Shigehisa O, Sunao I (1996) An overview of x-ray lithography. Microelectron Eng 30:171–178

Cerrina F (2000) X-ray imaging: applications to patterning and lithography. J Phys D Appl Phys 33:R103–R-116

Chou SY, Krauss PR, Renstrom PJ (1995) Imprint of sub-25 nm vias and trenches in polymers. Appl Phys Lett 67:3114–3116

Chou SY, Krauss PR, Renstrom PJ (1996) Imprint lithography with 25-nanometer resolution. Science 272:85–87

Helmut S (2008) Nanoimprint lithography: an old story in modern times? a review. J Vac Sci Technol B 26(2):458–480

Zankovych S, Hoffmann T, Seekamp J, Bruch JU, Torres CMS (2001) Nanoimprint lithography: challenges and prospects. Nanotechnology 12:91–95

Morecroft D et al (2009) Sub-15 nm nanoimprint molds and pattern transfer. J Vac Sci Technol B 27(6):2837–2840

Guo LJ (2004) Recent progress in nanoimprint lithography and its applications. J Phys D Appl Phys 37:R123–R141

Kim KS, Kim JH, Lee HJ, Lee SR (2010) Tribology issues in nanoimprint lithography. J Mech Sci Technol 24:2–12

Hulteen JC, Duyne RPV (1995) Nanosphere lithography: a materials general fabrication process for periodic particle array surfaces. J Vac Sci Technol A 13(3):1553–1558

Haynes CL, Duyne RPV (2001) Nanosphre lithography: a versatile nanofabrication tool for studies of size-dependent nanoparticle optics. J Phys Chem B 105(24):5599–5611

Cheung CL, Nikolic RJ, Reinhardt CE, Wang TF (2006) Fabrication of nanopillars by nanosphere lithography. Nanotechnology 17:1339–1343

Rashidi H, Yoshino M (2009) New approach to nanofabrication with non-photolithographic pattern transfer by nano plastic forming (NPF) and etching technologies. Proceedings of the 5th International Conference on Leading Edge Manufacturing in 21st Century (LEM21) December 2–4 Osaka, Japan, pp 289–292

Rashidi H, Yoshino M (2010) Fabrication of sub-20 nm nanostructures by nano plastic forming and etching (NPFE). J Micromech Microeng 20(9):095003

Yoshino M, Kurnia W (2009) Nano/micro structure fabrication of metal surfaces using the combination of nano plastic forming, coating and roller imprinting processes. J Micromech Microeng 19:125028–125038

Jacobson S, Jonsson B (1983) The use of fast heavy ions to improve thin film adhesion. Thin Solid Films 107:89–98

Pedraza AJ, Godbole MJ, Lowndes DH, Thompson JJR (1989) Enhanced metal-ceramic adhesion by sequential sputter deposition and pulsed laser melting of copper films on sapphire substrates. J Mater Sci 24(1):115–123

Ben AM, Bessueille F, Chovelon JM, Abdelghani A, Jaffrezic-Renault N, Maaref MA, Martelet C (2008) Use of ultra-thin organic silane films for the improvement of gold adhesion to the silicon dioxide wafers for (bio) sensor applications. Mater Sci Eng, C 28:628–632

Yoshino M, Aravindan S (2004) Nano-surface fabrication of hard brittle materials by structured tool imprinting. J Manuf Sci Eng 126:760–765

Yoshino M, Matsumura T, Umehara N, Akagami Y, Aravindan S, Ohno T (2006) Engineering surface and development of a new micro array chip. Wear 206(3):274–286

Yoshino M, Yoshizawa F, Matsumura T (2008) Control of optical transmittance by nano plastic forming. Int J Mater Forming 1:491–494

Yoshino M, Umehara N, Aravindan S (2009) Development of functional surface by nano plastic forming. Wear 266:581–584

Xin Z, Xiao-Hui S, Dian-Lin Z (2010) Thickness dependence of grain size and surface roughness for dc magnetron sputtered Au films. Chin Phys B 19(8):086802

Wu SZ (2005) Dependence of plasma characteristics on DC magnetron sputter parameters. J Apl Phys 98:083301

Chan KY, Teo BS (2007) Effect of Ar pressure on grain size of magnetron sputter-deposited Cu thin films. IET Sci Meas Technol 1(2):87–90

Chan KY, Teo BS (2006) Atomic force microscopy (AFM) and x-ray diffraction (XRD) investigations of copper thin films prepared by DC magnetron sputtering technique. Microelc J 37:1046–1071

Hoffman DW (1982) Internal stresses in Cr, Mo, Ta, and Pt films deposited by sputtering from a planar magnetron source. J Vac Sci Technol 20(3):355–358

Rossnagel SM (1989) Energetic particle bombardment of films during magnetron sputtering. J Vac Sci Technol A 7(3):1025–1029

Chinmulgund M, Inturi RB, Barnard JA (1995) Effect of Ar gas pressure on growth, structure, and mechanical properties of sputtered Ti, Al, TiAl, and Ti3Al films. Thin Solid Films 270:260–263

Thornton JA (1974) Influence of apparatus geometry and deposition conditions on the structure and topography of thick sputtered coatings. J Vac Sci Technol 11(4):666–670

Jing X, Guang-hui M, Li-jie H, Xia-hua Z, Hua-shun Y (2009) Dependence of characteristics of LaB6 films on DC magnetron sputtering power. Trans Nonferrous Met Soc China 19:952–955

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rashidi, H., Yoshino, M. Nanomanufacturing of densely packed ultra-fine nanostructures by nano plastic forming and etching (NPFE). Int J Adv Manuf Technol 57, 605–615 (2011). https://doi.org/10.1007/s00170-011-3307-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3307-5