Abstract

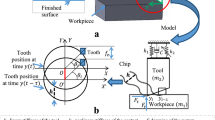

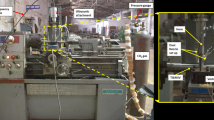

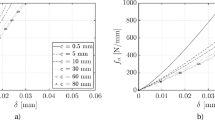

The aim of this study is to evaluate the modelling of machining vibrations of thin-walled aluminium workpieces at high productivity rate. The use of numerical simulation is generally aimed at giving optimal cutting conditions for the precision and the surface finish needed. The proposed modelling includes all the ingredients needed for real productive machining of thin-walled parts. It has been tested with a specially designed machining test with high cutting engagement and taking into account all the phenomena involved in the dynamics of cutting. The system has been modelled using several simulation techniques. On the one hand, the milling process was modelled using a dynamic mechanistic model, with time domain simulation. On the other hand, the dynamic parameters of the system were obtained step by step by finite element analysis; thus the variation due to metal removal and the cutting edge position has been accurately taken into account. The results of the simulations were compared to those of the experiments; the discussion is based on the analysis of the cutting forces, the amplitude and the frequency of the vibrations evaluating the presence of chatter. The specific difficulties to perfect simulation of thin-walled workpiece chatter have been finely analysed.

Similar content being viewed by others

References

Tobias SA, Fishwick W (1958) Theory of regenerative machine tool chatter. Engineer 205:199–203, 238–239

Tlusty J, Polácek M (1963) The stability of the machine tool against self-exited vibration in machining, Proceedings of the International Research in Production Engineering Conference. ASME, Pittsburgh, pp 465–474

Altintas Y, Budak E (1995) Analytical prediction of stability lobes in milling. Ann CIRP 44:357–362

Altintas Y (2000) Manufacturing automation. Cambridge University, Cambridge

Bayly PV, Halley JE, Mann BP, Davies MA (2003) Stability of interrupted cutting by temporal finite element analysis. Trans ASME J Manuf Sci Eng 125:220–225

Insperger T, Stépán G (2004) Uptaded semi-discretization method for periodic delay-differential equations with discrete delay. Int J Numer Meth Eng 61:117–141

Insperger T, Stépán G, Turi J (2008) On the higher-order semi-discretizations for periodic delayed systems. J Sound Vib 313:334–341

Davies MA, Pratt JR, Dutterer B, Burns TJ (2002) Stability prediction for low radial immersion milling. Trans ASME J Manuf Sci Eng 124:217–225

Insperger Y, Mann BP, Stépán G, Bayly PV (2003) Stability of up-milling and down-milling, Part 1: alternative analytical methods. Int J Mach Tools Manuf 43:25–34

Campomanes ML, Altintas Y (2003) An improved time domain simulation for dynamic milling at small radial immersions. Trans ASME J Manuf Sci Eng 125:416–422

Lapujoulade F, Mabrouki T, Raïssi K (2002) Prédiction du comportement vibratoire du fraisage latéral de finition des pièces à parois minces. Mec Ind 3:403–418

Thevenot V, Arnaud L, Dessein G, Cazenave-Larroche G (2006) Influence of material removal on dynamic behavior of thin walled structure in peripheral milling. Mach Sci Technol 10:275–287

Thevenot V, Arnaud L, Dessein G, Cazenave-Larroche G (2006) Integration of dynamic behaviour in stability lobes method: 3D lobes construction and application to thin walled structure milling. Int J Adv Manuf Technol 27:638–644

Seguy S, Campa FJ, López de Lacalle LN, Arnaud L, Dessein G, Aramendi G (2008) Toolpath dependent stability lobes for the milling of thin-walled parts. Int J Mach Machinabil Mater 4:377–392

Bravo U, Altuzarra O, López de Lacalle LN, Sánchez JA, Campa FJ (2005) Stability limits of milling considering the flexibily of the workpiece and the machine. Int J Mach Tools Manuf 45:1669–1680

Herranz S, Campa FJ, López de Lacalle LN, Rivero A, Lamikiz A, Ukar E, Sánchez JA, Bravo U (2005) The milling of airframe components with low rigidity: a general approach to avoid static and dynamic problems. P I Mech Eng B J Eng Manuf 219:789–801

Kline WA, Devor RE, Lindberg JR (1982) The prediction of cutting forces in end milling with application to cornering cuts. Int J Mach Tool Des Res 22:7–22

Engin S, Altintas Y (2001) Mechanics and dynamics of general milling cutters, part I: helical end mills. Int J Mach Tools Manuf 41:2195–2212

Tlusty J, Ismail F (1981) Basic non-linearity in machining chatter. Ann CIRP 30:299–304

Tlusty J (1986) Dynamics of high speed milling. Trans ASME J Eng Ind 108:59–67

Smith S, Tlusty J (1993) Efficient simulation programs for chatter in milling. Ann CIRP 42:463–466

Montgomery D, Altintas Y (1991) Mechanism of cutting force and surface generation in dynamic milling. Trans ASME J Eng Ind 113:160–168

Peigné G, Paris H, Brissaud D (2003) A model of milled surface generation for time domain simulation of high-speed cutting. P I Mech Eng B J Eng Manuf 217:919–930

Surmann T, Enk D (2007) Simulation of milling tool vibration trajectories along changing engagement conditions. Int J Mach Tools Manuf 47:1442–1448

Altintas Y, Montgomery D, Budak E (1992) Dynamic peripheral milling of flexible structures. Trans ASME J Eng Ind 114:137–145

Li H, Shin YC (2006) A comprehensive dynamic end milling simulation model. Trans ASME J Manuf Sci Eng 128:86–95

Lorong P, Coffignal G, Cohen-Assouline S (2008) Simulation du comportement dynamique d’un système usinant: modélisation de l’interaction outil/matière en présence d’une pièce flexible. Mec Ind 9:117–124

Seguy S, Dessein G, Arnaud L (2008) Surface roughness variation of thin wall milling, related to modal interactions. Int J Mach Tools Manuf 48:261–274

Gonzalo O, Peigné G, Gonzalez D (2006) High speed machining simulation of thin-walled components, 5th International Conference on High Speed Machining. Metz, France

Paris H, Brissaud D, Gouskov A (2007) A more realistic cutting force model at uncut chip thickness close to zero. Ann CIRP 56:415–418

Turner S, Merdol D, Altintas Y, Ridgway K (2007) Modelling of the stability of variable helix end mills. Int J Mach Tools Manuf 47:1410–1416

Author information

Authors and Affiliations

Corresponding author

Additional information

Sadly, Grégoire Peigné died during the preparation of the article.

Rights and permissions

About this article

Cite this article

Arnaud, L., Gonzalo, O., Seguy, S. et al. Simulation of low rigidity part machining applied to thin-walled structures. Int J Adv Manuf Technol 54, 479–488 (2011). https://doi.org/10.1007/s00170-010-2976-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2976-9