Abstract

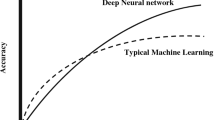

Camshaft grinding is more complex comparing with the ordinary cylindrical grinding. Since its quality is mostly influenced by more factors, how to select process parameters quickly and accurately becomes the key to improve its quality and processing efficiency. In this paper, a hybrid artificial neural network (ANN) and genetic algorithm (GA) model is proposed to optimize the process parameters. In this method, a BP neural network model is developed to map the complex nonlinear relationship between process parameters and processing requirements, and a GA is used in order to improve the accuracy and speed based on the ANN model. The results show that the hybrid ANN/GA model is an effective tool for the process parameters optimization in NC camshaft grinding.

Similar content being viewed by others

References

Ipek R, Selcuk B (2005) The dry wear profile of cam shaft. J Mater Process Technol 168(3):373–376. doi:10.1016/j.jmatprotec.2004.09.080

Wang G, Taylor D, Bouquin B, Ciepalowicz A (2000) Prediction of fatigue failure in a camshaft using the crack modelling method. Eng Fail Anal 7(3):189–197. doi:10.1016/S1350-6307(99)00015-1

Chen SL, Jen YW (2000) Data fusion neural network for tool condition monitoring in CNC milling machining. Int J Mach Tools Manuf 40(3):381–400. doi:10.1016/S0890-6955(99)00066-8

Wang SB, Wu CF (2006) Selections of working conditions for creep feed grinding.Part(III): avoidance of the workpiece burning by using improved BP neural network. Int J Adv Manuf Technol 28:31–37. doi:10.1007/s00170-004-2343-9

Liu JT, Chang HB, Hsu TY, Ruan XY (2000) Prediction of the flow stress of high-speed steel during hot deformation using a BP artificial neural network. J Mater Process Technol 103(2):200–205. doi:10.1016/S0924-0136(99)00444-6

Fuh KH, Wang SB (1997) Force modeling and forecasting in creep feed grinding using improved bp neural network. Int J Mach Tools Manuf 37(8):1167–1178. doi:10.1016/S0890-6955(96)00012-0

Sreeram S, Kumar AS, Rahman M, Zaman MT (2006) Optimization of cutting parameters in micro end milling operations under dry cutting conditions using genetic algorithms. Int J Adv Manuf Technol 30:1030–1039. doi:10.1007/s00170-005-0148-0

Raid AA, Ala’a AO (2006) A GA-based parameter design for single machine turning process with high-volume production. Comput Ind Eng 50(3):317–337. doi:10.1016/j.cie.2006.02.003

Yuen CWM, Wong WK, Qian SQ, Chan LK, Fung EHK (2009) A hybrid model using genetic algorithm and neural network for classifying garment defects. Expert Syst Appl 36(2):2037–2047. doi:10.1016/j.eswa.2007.12.009

Park YW, Rhee S (2008) Process modeling and parameter optimization using neural network and genetic algorithms for aluminum laser welding automation. Int J Adv Manuf Technol 37:1014–1021. doi:10.1007/s00170-007-1039-3

Tu Z (1998) Theoretical Analysis and Programmer Design of the software about NC camshaft grinding machine. MS Thesis, Beijing Institute of Machinery. (in Chinese)

Wang AZ, Wang Z (2008) Research on dressing method and technology for vitrified CBN grinding wheel. Diam Abrasives Eng 164(2):64–68 in Chinese

Wang HJ, Han QS (2008) The software development of grinding parameter optimization model for NC camshaft grinder based on BP. Modern Manufacturing Engineering 5:26–71 (in Chinese)

Kuo Y, Yang T, Peters BA, Chang I (2007) Simulation metamodel development using uniform design and neural networks for automated material handling systems in semiconductor wafer fabrication. Simul Model Pract Theory 15(8):1002–1015. doi:10.1016/j.simpat.2007.05.006

Wang Y, Fang KT, Maringer D, Tang Y, Winker P (2004) The uniform design. http://www.math.hkbu.edu.hk/uniformdesign

Zhou KL, Kang YH (2005) Neural network model and simulation program designed with MATLAB. Tsinghua University press, Beijing in Chinese

Nandi AK, Banerjee MK (2005) FBF-NN-based modelling of cylindrical plunge grinding process using a GA. J Mater Process Technol 162–163:655–664. doi:10.1016/j.jmatprotec.2005.02.080

Nandi AK, Pratihar DK (2004) Design of a genetic-fuzzy system to predict surface finish and power requirement in grinding. Fuzzy Sets Syst 148(3):487–504. doi:10.1016/j.fss.2003.10.001

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deng, Z.H., Zhang, X.H., Liu, W. et al. A hybrid model using genetic algorithm and neural network for process parameters optimization in NC camshaft grinding. Int J Adv Manuf Technol 45, 859–866 (2009). https://doi.org/10.1007/s00170-009-2029-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-2029-4