Abstract

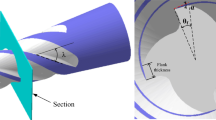

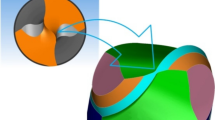

A novel method using a CBN spherical grinding wheel to grind the rake face of a taper ball-end mill and the configuration of corresponding CNC tool grinder are presented. This method utilizes the self-adaptation characteristics of a sphere to decrease the number of simultaneous cooperative axes of a CNC tool grinder and to smooth the rake face on the transition area between the taper and the ball-end of the mill. In order to obtain an accurate normal rake angle, which is one of the key factors affecting tool cutting performance, a moving coordinate system based on the required normal rake angle and the cutting edge was established. Then, by the proposed moving coordinate system, an algorithm to determine the position and orientation of a spherical grinding wheel, the basis of CNC code generation, is proposed and the relevant formulations are deduced. The 3D simulation of rake face grinding for a taper ball-end mill with constant helical angle indicates that the number of simultaneous cooperative axes of the CNC tool grinder is decreased from five to four and the smooth transition of the rake face is realized by the proposed method herein.

Similar content being viewed by others

References

Jin M, Goto I, Watanabe T, Kurosawa JI, Murakawa M (2007) Development of CBN ball-nosed end mill with newly designed cutting edge. J Mater Process Technol 192–193:48–54 DOI 10.1016/j.jmatprotec.2007.04.054

Lu Y, Takeuchi Y, Takahashi I, Anzai M (2005) An integrated system development for ball end mill design, creation and evaluation. Int J Adv Manuf Technol 25:628–646 DOI 10.1007/s00170–004–2259–4

Tsai YC, Hsieh JM (2005) An analysis of cutting-edge curves and machining performance in the Inconel 718 machining process. Int J Adv Manuf Technol 25:248–261 DOI 10.1007/s00170–003–1869–6

Takeuchi Y, Nagasaka M, Morishige K (1996) 5-axis control machining with top and side cutting edges of ball end mill. J Adv Autom Technol 8(1):30–36

Larue A, Altintas Y (2005) Simulation of flank milling processes. Int J Mach Tools Manuf 45:549–559 DOI 10.1016/j.ijmachtools.2004.08.020

Imani BM, Sadeghi MH, Elbestawi MA (1998) An improved process simulation system for ball-end milling of sculptured surfaces. Int J Mach Tools Manuf 38:1089–1107 DOI 10.1016/S0890–6955(97)00074–6

Xiong F, Bin HZ, Jin JX (2001) 3D graphical simulation of CNC grinding for complex shaped cutters. Chin Mech Eng 12(11):1253–1255 1275

Puig A, Pérez-Vidal L, Tost D (2003) 3D simulation of tool machining. Comput Graph 27:99–106 DOI 10.1016/S0097–8493(02)00248–0

Kaldor S, Trendler PHH, Hodgson T (1985) Investigation and optimization of the clearance geometry of end mills. Ann CIRP 34(1):149–154

Gong ZH, Bin HZ (1994) The definition of “Generalized Spiral Angle” and its application. Chin Mech Eng 5(1):14–15

Mao SM, Nie G, Wu XT (1999) Three axes numerical control machining of taper mill cutter with equal helical angle and controllable rake angle. J Xi’an JiaoTong Univ 33(7):79–83

Chen CK, Lin RY (2001) A study of manufacturing models for ball-end type rotating cutters with constant pitch helical grooves. Int J Adv Manuf Technol 18:157–167 DOI 10.1007/s001700170071

Altintas Y, Engin S (2001) Generalized modeling of mechanics and dynamics of milling cutters. Ann CIRP 50(1):25–30

Gong ZH, Bin HZ (1997) Cutting edge point following CNC grinding method and its application in cone ball-end mill. Tool Eng 31(9):19–24

Chen CB, Wang FS, Chang PC, Hwang JH, Chen WF (2006) A precision design and NC manufacturing model for concave-arc ball-end cutters. Int J Adv Manuf Technol 31:283–296 DOI 10.1007/s00170–005–0186–7

Chen WY, Chang PC, Liaw SD, Chen WF (2005) Study of design and manufacturing models for circular-arc ball-end milling cutters. J Mater Process Technol 161:467–477 DOI 10.1016/j.jmatprotec.2004.07.086

Liu HR (1995) Study on smooth connection of edge curve of ball end mill. Tool Eng 29(9):11–13

Liu JY, Liu HM, Wang YF (1998) Study on the uniform model of helical cutting edges of tools. Tool Eng 32(6):24–26

Liu JY, Liu HM, Liu HL (1998) Geometric model and NC grinding model and computer simulation of ball end mill with constant normal rake angle. Tool Eng 32(3):3–5

Xiong F, Bin HZ (2003) CNC rake grinding for a taper ball end mill with torus-shaped grinding wheel. Int J Adv Manuf Technol 21:549–555 DOI 10.1007/s00170–002–1298-y

Hsieh JM (2008) Manufacturing models for design and NC grinding of truncated-cone ball-end cutters. Int J Adv Manuf Technol 35:1124–1135 DOI 10.1007/s00170–006–0794-x

Hsieh JM, Tsai YC (2006) Geometric modeling and grinder design for toroid-cone shaped cutters. Int J Adv Manuf Technol 29:912–921 DOI 10.1007/s00170–005–2613–1

Han CS, Tang YY, Dong S (2005) A research on the non-NC machining of two kinds of revolving cutters. Int J Adv Manuf Technol 161:485–490

Pei BQ, Luo XK, Chen WY (2004) Processing model of rake and flank faces of ball-end cutters with a virtual axis grinding machine. J Beijing Univ Aeronaut Astronaut 30(7):602–605

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, F., Bin, H. A novel CNC grinding method for the rake face of a taper ball-end mill with a CBN spherical grinding wheel. Int J Adv Manuf Technol 41, 846–857 (2009). https://doi.org/10.1007/s00170-008-1554-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1554-x