Abstract

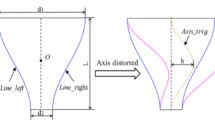

Metal flow in the extrusion process is an important factor in controlling the mechanical properties of the extruded products. It is, however, difficult to predict the metal flow in three-dimensional extrusion of sections due to the involvement of re-entrant corners. The present work is an attempt to find an upper bound solution for the extrusion of channel section from round billet through the taper die. The rigid-perfectly plastic model of the material is assumed, and the spatial elementary rigid region (SERR) technique is presented for which the kinematically admissible velocity field is found out by minimizing the plastic dissipation of power. The presented analysis allows for specification of process control parameters and their relation to extrusion load, equivalent die angle, reduction ratios and friction factor.

Similar content being viewed by others

References

Juneja BL, Prakash R (1975) An analysis for drawing and extrusion of polygonal sections. Int J MTDR 15:1–30

Chitkara NR, Adeyemi MB (1977) Working pressure and deformation modes in forward extrusion of I and T shaped sections from square sludge. Proc 8th IMTDR Conf, London: 39–46

Prakash R, Khan OH (1979) An analysis of plastic flow through polygonal converging dies with generalised boundaries of the zone of plastic deformation. Int J MTDR 19:1–19

Nagpal V (1977) On the solution of three-dimensional metal forming process. Trans ASME Series B J Eng Ind 99:624–629

Nagpal V, Billhardt CF, Altan T (1979) Lubricated extrusion of “T” section from aluminium, titanium and steel using computer aided techniques. Trans ASME Series B J Eng Ind 101:319–324

Nagpal V, Altan T (1975) Analysis of the three-dimensional metal flow in extrusion of shapes with the use of dual stream function. Proc Third N Am Met Res Conf, Pittsburgh, Pennsylvenia: 26–40

Basily BB, Sansome DH (1976) Some theoretical considerations for the direct drawing of section rod from round bar. Int J Mech Sci 18:201–209. doi:10.1016/0020-7403(76)90026-6

Yang DY, Lee CH (1978) Analysis of three-dimensional extrusion of sections through curved dies by conformal transformations. Int J Mech Sci 20:541–552. doi:10.1016/0020-7403(78)90012-7

Prakash R, Khan OH (1979) An analysis of plastic flow through polygonal converging dies with generalized boundaries of the zone of plastic deformation. Int J MTDR 19:1–9

Boer CB, Schneider WR, Avitzur B (1980) An upper bound approach for the direct drawing of square section rod from round bar. Proc 20th Int MTDR Conf, Birmingham: 149–156

Gatto F, Giarda A (1981) The characteristics of three-dimensional analysis of plastic deformation according to the SERR method. Int J Mech Sci 23:129–148. doi:10.1016/0020-7403(81)90025-4

Gunasekera JS, Hosino S (1982) Analysis of extrusion or drawing of polygonal sections through straightly conversing dies. Trans ASME Series B J Eng Ind 104:38–45

Maity KP, Kar PK, Das NS (1996) A class of upper-bound solutions for the extrusion of square shapes from square billets through curved dies. J Mater Process Technol 62(1–3):185–190. doi:10.1016/0924-0136(95)02228-7

Kim DK, Cho JR, Bae WB, Kim YH, Bramley AN (1997) An upper bound analysis of the square-die extrusion of non-axisymmetric sections. J Mater Process Technol 71(3):477–486. doi:10.1016/S0924-0136(97)00116-7

Kar PK, Das NS (1997) Upper bound analysis of extrusion of I-section bars from square and rectangular billets through square dies. Int J Mech Sci 39(8):925–934. doi:10.1016/S0020-7403(96)00097-5

Wu CW, Hsu RO (2000) Theoretical analysis of extrusion of rectangular, hexagonal and octagonal composite clad rods. Int J Mech Sci 42:473–486. doi:10.1016/S0020-7403(99)00011-9

Sahoo SK (2000) Comparison of SERR analysis in extrusion with experiment. J Mater Process Technol 103(2):293–303. doi:10.1016/S0924-0136(99)00480-X

Sahoo SK, Kar PK, Singh KC (1998) Upper-bound analysis of the extrusion of a bar of channel section from square/rectangular billets through square dies. J Mater Process Technol 75(1–3):75–80. doi:10.1016/S0924-0136(97)00285-9

Chitkara NR, Celik KFA (2001) Extrusion of non-symmetric T-shaped sections on analysis and some experiments. Int J Mech Sci 43:2961–2987. doi:10.1016/S0020-7403(01)00044-3

Qamar SZ, Arif AFM, Sheikh AK (2004) Analysis of product defects in a typical aluminum extrusion facility. Mater Manuf process 19(3):391–405. doi:10.1081/AMP-120038650

Narayanasamy R, Ponalagusamy R, Venkatesan R, Srinivasan P (2006) An upper bound solution to extrusion of circular billet to circular shape through cosine die. Mater Des 27(5):411–415. doi:10.1016/j.matdes.2004.11.026

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sahoo, R.K., Samantaray, P.R., Sahoo, S.K. et al. Round-to-channel section extrusion through linearly converging die: a three-dimensional analysis. Int J Adv Manuf Technol 41, 677–683 (2009). https://doi.org/10.1007/s00170-008-1511-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1511-8