Abstract

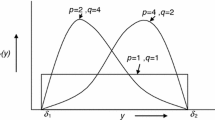

The CUSUM charts have been widely used in statistical process control (SPC) across industries for monitoring process shifts and supporting online measurement and distributed computing. This paper proposes an algorithm for the optimimal design of a CUSUM control chart detecting process shifts in the mean value. The algorithm optimizes the sample size, sampling interval, control limit and reference parameter of the CUSUM chart through minimizing the overall mean value (ML) of a Taguchi’s loss function over the probability distribution of the random process mean shift. A new feature related to the exponential of the sample mean shift is elaborated. Comparative studies reveal that the proposed ML-CUSUM chart is considerably superior to the Shewhart ML-\(\overline{X} \) chart and the conventional CUSUM chart in terms of the overall loss of ML.

Similar content being viewed by others

References

Page ES (1954) Control charts for the mean of a normal population. J R Stat Soc 16:131–135

Keats JB, Miskulin JD, Runger GC (1995) Statistical process control scheme design. J Qual Technol 27:214–225

Prabhu SS, Runger GC, Montgomery DC (1997) Selection of the subgroup size and sampling interval for a CUSUM control chart. IIE Trans 29:451–457

Wu Z, Spedding TA (2000) A synthetic control chart for detecting small shifts in the process mean. J Qual Technol 32:32–38

Wu Z, Spedding TA (2000) Implementing synthetic control charts. J Qual Technol 32:75–78

Zhang S, Wu Z (2005) Designs of the control charts with supplementary runs rules. Comput Ind Eng 49:76–97

Duncan AJ (1956) The economic design of \(\overline{X} \) charts used to maintain current control of a process. J Am Stat Assoc 51:228–242

Montgomery DC (1986) Economic design of an \(\overline{X} \) control chart. J Qual Technol 14:40–43

Castillo ED, Montgomery DC (1996) A general model for the optimal design of \(\overline{X} \) charts used to control short or long run processes. IIE Trans 28:193–201

Al-Oraini HA, Rahim MA (2002) Economic statistical design of \(\overline{X} \) control charts for systems with gamma (λ, 2) in-control times. Comput Ind Eng 43:645–654

Woodall WH (1986) Weaknesses of economical design of control charts. Technometrics 28:408–409

Montgomery DC (2005) Introduction to statistical quality control. John Wiley & Sons, Singapore

Wu Z, Shamsuzzaman M, Pan ES (2004) Optimization design of the control charts based on Taguchi’s loss function and random process shifts. Int J Prod Res 42:379–390

Spring FH, Yeung AS (1998) A general class of loss functions with individual applications. J Qual Technol 30:152–162

Ross PJ (1989) Taguchi techniques for quality engineering, loss function, orthogonal experiments, parameter and tolerance design. McGraw-Hill International Editions, New York

Woodall WH, Montgomery DC (1999) Research issues and ideas in statistical process control. J Qual Technol 31:376–386

Reynolds MR Jr, Stoumbos ZG (2004) Should observations be grounded for effective process monitoring. J Qual Technol 36:343–366

Wheeler DJ (1983) Detecting a shift in process average: tables of the power function for charts. J Qual Technol 15:155–170

Saniga EM (1989) Economic statistical control chart designs with an application to \(\overline{X} \) and R chart. Technometrics 31:313–320

Wu Z, Xie M, Tian Y (2002) Optimization design of the \(\overline{X} \)&S charts for monitoring process capability. J Manuf Syst 21:83–92

Wu Z, Tian Y (2005) Weighted-loss-function CUSUM chart for monitoring mean and variance of a production process. Int J Prod Res 43:3027–3044

Reynolds MR Jr, Amin RW, Arnold JC (1990) CUSUM charts with variable sampling intervals. Technometrics 32:371–384

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiao, J.R., Helo, P.T. Optimization design of a CUSUM control chart based on taguchi’s loss function. Int J Adv Manuf Technol 35, 1234–1243 (2008). https://doi.org/10.1007/s00170-006-0803-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0803-0