Abstract

Process shift is an important input parameter in the economic design of control charts. Earlier control chart designs considered constant shifts to occur in the mean of the process for a given assignable cause. This assumption has been criticized by many researchers since it may not be realistic to produce a constant shift whenever an assignable cause occurs. To overcome this difficulty, in the present work, a distribution for the shift parameter has been considered instead of a single value for a given assignable cause. Duncan’s economic design model for chart has been extended to incorporate the distribution for the process shift parameter. It is proposed to minimize total expected loss-cost to obtain the control chart parameters. Further, three types of process shifts namely, positively skewed, uniform and negatively skewed distributions are considered and the situations where it is appropriate to use the suggested methodology are recommended.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

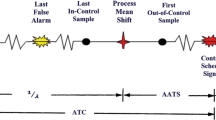

In the economic design of control charts a set of cost and process parameters are used to obtain the control chart parameters. For an control chart the input parameters include certain cost parameters such as cost of false alarm, the cost of finding an assignable cause etc., and certain process parameters like failure rate of the process and process shift parameter. Economic designs are observed to be very sensitive to process shift parameter (δ) in comparison with other parameters (Montgomery 1980). In order to obtain the full benefits of economic designs, one has to consider the appropriate values of shift parameter. Earlier designs relied on the use of constant process shift for a single assignable cause. This has been criticized by some of the researchers since it is not realistic to assume that a single assignable cause would always produce the same shift whenever it occurs. The following statements support the significance of the process shift in the economic designs:

Chiu and Wetherill (1974): “δ is a critical risk parameter; of which we must strive to obtain an accurate estimate.”

Saniga (1992): “economic models are economic only if the shift upon which the model is developed is the shift that occurs”.

Ho and Case (1994): “the assumption that a certain cause will shift the process by a known shift is totally unrealistic.”

Hence, the economic designs entail the use of appropriate process shift parameter for obtaining better designs. Since an assignable cause does not always produce a single shift, the process shifts can be considered in the following three ways:

-

1.

Different known discrete values of the shifts.

-

2.

A possible range for shift values with unknown distribution.

-

3.

A known or assumed distribution of the shift values.

The procedures to find the optimal designs have been discussed for the first and second cases (Pignatillo and Tsai 1988; Linderman and Choo 2002; Vommi and Seetala 2007a, b). The present work deals with finding the optimal control chart design when the process shift follows a distribution within a range of values. Everlasting interest in finding the better control charts in process monitoring is evident from Niaki and Khedmati (2013) who proposed a new control chart to monitor the change time of multivariate binomial processes for step changes and drifts.

In the economic designs, various authors have studied genetic algorithms as a search tool when it is difficult to obtain closed form solutions by differentiating the cost functions. Arunkumar et al. (2007) studied the use of genetic algorithm for selection of vendors offering quantity discounts. Izadi and Kimiagari (2014) designed a distribution network under uncertain demand using genetic algorithm to minimize various costs.

Extension of Duncan’s economic model

Duncan (1956) proposed an economic model for the optimum economic design of the control chart. Duncan’s economic model minimizes E(L), the expected loss-cost per hour incurred by the process, to obtain the best parameters of the control chart. The expected loss-cost function is given below:

The above expected loss-cost is based on the assumption that an assignable cause always produces a single known shift. In the present study, the assignable cause is assumed to produce different shift values within a known range. The distribution of the shift parameter δ can be known in the long run. Hence, the shift distribution can be assumed to follow a probability distribution. In order to extend the economic design for different process shifts, the expected loss-cost function given in Eq. (1) has to be modified such that it accommodates the process shift distribution. As the range of the process shift distribution will be finite and occurs between two possible values, a beta distribution function is considered for representing the process shift parameter (δ).

The probability density function of the process shift can be given as:

where Y is the beta distributed random variable of process shift with δ1 and δ2 as lower and upper values, respectively. B(p, q) is the beta function with p and q as its parameters and it is calculated as follows:

Depending on the parameters p and q, the density function of the beta random variable will have different shapes as shown in the Fig. 1. For example, p = 2 and q = 4 represents a positively skewed distribution. Similarly, p = 4 and q = 2 represents a negatively skewed distribution. Whenever p and q take non-integer values, the beta function is called the incomplete beta function. The cumulative probability of the incomplete beta function is tabulated by Pearson as B Y (p, q). Hence, Pearson’s tables can be used to calculate the cumulative probability of a beta random variable, y. It can be noted that the tables are given for p ≥ q. For p < q, .

Considering a beta probability distribution function for the shift parameter, the probability that the shift parameter, y occurs is f Y (y)dy. Hence, the expected loss-cost is given by:

In order to find out the best control chart parameters in the present case, the total expected loss-cost function as given by the following equation must be minimized.

Using Duncan’s loss-cost function E(L), the extended total expected loss-cost per hour (TE(L)) incurred by the process can be written as:

The probabilities of type I and type II error are computed as follows:

Probability of type I error, α = 2φ(−k).

Probability of type II error, .

Optimization of the above Eq. (6) for finding the optimal control chart parameters is considered in the present economic design of control chart problem with a known process shift distribution. Since the optimization of the Eq. (6) involves finding the closed form solutions for the following Eqs. (7),(8) and (9), which poses difficulties in obtaining the control chart parameters, an evolutionary optimization technique, namely a genetic algorithm (GA) has been used to obtain near global optimum results.

The total expected loss as given in Eq. (6) considers only the shift parameter ranges and neglects the variation in the hourly cost of not detecting the shifts. There is definitely a variation in the cost parameter a5 since larger shifts tend to produce higher values of a5 and smaller ones relatively a lower value of a5. But, the variation in this cost parameter is omitted in the present analysis owing to the simplicity of the model on the following grounds: (1) the effect of cost parameters is not considerable in comparison with the shift parameter, (2) the larger shifts have the tendency to be detected early and the smaller shifts may take more time to be detected. Hence, on average the penalty of not detecting the shifts per hour can be taken as a constant.

Optimal designs considering shift distributions using GA

The best design parameters of the control chart are to be obtained by minimizing the total expected loss-cost function for a given set of cost and process parameters. Employing an appropriate optimization technique may not pose difficulties in optimizing the total loss-cost Eq. (6) for a given set of cost and process parameters. Use of GA in the economic designs is very common, since it helps to find the near global solutions for very complicated objective functions (Chen and Yeh 2009). Present study employs a binary coded genetic algorithm in optimization. The ranges of control chart parameters considered are given in the Table 1. The cost and process parameters for the present designs are chosen from the earlier works of Duncan (1956) and Panagos et al. (1985) corresponding to the shift parameter of value 2. It can be noted that Duncan’s work utilizes a wide range of cost parameters as compared to the most recent examples of the control chart designs. Since the present methodology utilizes the process shift distribution, in place of a constant process shift parameter δ = 2, process shift parameter ranges are chosen as [0.5 1.5], [0.5 2.5] and [0.5 3.5]. The lower value of the shift parameter is taken as 0.5 because the Shewhart’s control charts are not preferred for smaller shifts. Different upper values, namely 1.5, 2.5 and 3.5 are considered for the shift parameters. Control chart designs are obtained using different cost and process parameters and assuming positively skewed (p = 2, q = 4), negatively skewed (p = 4, q = 2) and uniformly distributed (p = 1, q = 1) beta random variable as process shifts.

Genetic algorithms are optimization algorithms based on the natural evolution of the species (Goldberg 1984). The search for the global optimum value in optimization problems is carried out by randomly choosing an initial population from the feasible solution space and creating a new population containing possibly better solutions through the application of genetic operators. Since, the parameters of GA are specific, parametric tuning has been carried out and the GA parameters used in the study have been shown in the Table 2.

The optimization process can either be terminated when there is no improvement in the objective function value for a specified number of generations or when the specified number of generations is completed. Present problem is observed to converge before 300 generations in all cases; hence the maximum number of generations is taken as 300. A linear ranking method with selective pressure of two is used for fitness values. The optimal control chart design parameters obtained by the present methodology are presented in the Tables 3, 4 and 5. The example problems extracted from Duncan (1956) are numbered as D1, D2 etc., and those from Panagos et al. (1985) are numbered as P1, P2 etc.

Advantage of using process shift distributions in control chart designs

Obviously, the control chart designs considering a single shift parameter are simple and can be solved without using an evolutionary optimization technique. Considering shift distributions in the economic designs complicates the optimization process. Hence, the use of shift distribution has to be justified over using a single parameter for the process shift. It is assumed that the designer would consider the average of the extreme shift values in finding the single shift parameter for the design. The advantage of using shift distribution, which results in cost reduction, can be realized by using the following procedure:

-

1.

Minimize the expected loss-cost function, E(L) and obtain the optimal control chart parameters at single shift parameter which is the average of the minimum and maximum values of the shift parameter.

-

2.

Minimize the total expected loss-cost function TE(L) and obtain the optimal control chart parameters (n*h*k*) by considering the shift distribution in the range [δ1δ2]. The minimum total expected cost pertaining to these control chart parameters is TE(L*).

-

(3)

Substitute the control chart parameters obtained by minimizing the E(L) in the total expected loss-cost function [Eq. (6)] in order to find out TE(L0).

-

(4)

Finally, the percentage of cost reduction due to the consideration of shift distribution over a single parameter for process shift can be calculated as:

The cost values obtained for the designs under consideration are shown in the Table 6.

Results

It can be observed from the results that the cost values are influenced by the type of shift distribution and the range of the shift parameter. The advantage of using the present methodology is striking for positively skewed distribution and also for uniformly distributed shift parameters. The benefits are not remarkable for negatively skewed shift distributions. Also, when the shift range is wide, the advantage of using the present methodology is high. Figure 2 shows the variation of the maximum reductions in loss-cost obtained under consideration of different beta parameters and shift ranges.

From the present study, it can be observed that a maximum reduction in the loss-cost up to 36.90 % is achieved when the shift follows a uniform distribution. Similarly, a cost reduction of up to 40.15 % is achieved for a positively skewed shift distribution. Economic designs with the process shift following a negatively skewed distribution do not offer much monetary benefits with the present methodology.

Conclusions

Economic designs which consider a fixed shift to occur in the process for an assignable cause are criticized by earlier researchers to be totally unrealistic. Hence, there is a need to consider different shifts produced by the assignable cause. In the long run, the shifts may produce a distribution which may be positively skewed, negatively skewed or uniformly distributed. In the present work, for a given assignable cause, the process shift is considered to follow a probability distribution which can represent different situations. Beta distribution is considered for representing the process shift. Duncan’s (1956) model of economic design has been extended to accommodate the process shift distribution. The extended model uses total expected loss-cost per hour incurred by the process for obtaining optimum designs. GA based search has been used for minimizing the total expected loss-cost function. The cost and process parameters have been drawn from Duncan (1956) and Panagos et al. (1985). Economic designs have been obtained when the shift follows positively skewed, negatively skewed and uniform distributions by varying the parameters of the beta distribution with different shift ranges.

The control chart designs obtained using a distribution for process shift and the designs with a single process shift based on the average of the extreme values of shift parameters have been compared. Hence, it can be concluded that the present methodology has to be adopted when the shift distributions are either positively skewed or uniform. For a negatively skewed distribution, as the benefits are not remarkable, designs can be made based on a single process shift instead of using the shift distribution.

Abbreviations

- a 1 :

-

Fixed cost of sampling ($)

- a 2 :

-

Variable cost of sampling ($)

- a 3 :

-

Cost of finding an assignable cause ($)

- a 4 :

-

Cost of investigating a false alarm ($)

- a 5 :

-

Hourly penalty cost for operating in the out-of-control state ($)

- λ :

-

Process failure rate (h−1)

- g :

-

Time to test and interpret the result per sample unit (h)

- D :

-

Time required to find the assignable cause (h)

- δ :

-

Process shift parameter when a single shift is considered

- α :

-

Probability of type I error

- β :

-

Probability of type II error

- τ :

-

Expected time of occurrence of the assignable cause between consecutive samples

- ϕ(·):

-

Distribution function of standard normal random variable

- n :

-

Sample size

- h :

-

Sampling interval (h)

- k :

-

Width of the control limit

- Γ(·):

-

Gamma function

- y :

-

Beta distributed random variable of process shift

- δ 1 :

-

Lower limit of the process shift parameter range

- δ 2 :

-

Upper limit of the process shift parameter range

- p, q:

-

Parameters of beta distribution

- E(L):

-

Expected loss-cost per hour ($ h−1)

- TE(L):

-

Total expected loss-cost per hour ($ h−1)

References

Arunkumar N, Karunamoorthy L, Uma Makeshwaraa N (2007) An optimization technique for vendor selection with quantity discounts using genetic algorithm. J Ind Eng Int 3:1–13

Chen FL, Yeh CH (2009) Economic statistical design of non-uniform sampling scheme x control charts under non-normality and Gamma shock using genetic algorithm. Expert Syst Appl 36:9488–9497

Chiu WK, Wetherill GB (1974) A simplified scheme for the economic design of x control charts. J Qual Technol 6:63–69

Duncan AJ (1956) The economic design of x charts used to maintain current control of a process. J Am Stat Assoc 51:228–242

Goldberg DE (1984) Genetic algorithms in search, optimization and machine learning. Addison Wesley Logman Inc, USA

Ho CC, Case K (1994) Economic design of control charts: a literature review for 1981–1991. J Qual Technol 12:39–53

Izadi A, Kimiagari AM (2014) Distribution network design under demand uncertainty using genetic algorithm and Monte Carlo simulation approach: a case study in pharmaceutical industry. J Ind Eng Int 10:1–9

Linderman K, Choo AS (2002) Robust economic control chart design. IIE Trans 34:1069–1078

Montgomery DC (1980) The economic design of control charts: a review and literature survey. J Qual Technol 12:75–87

Niaki STA, Khedmati M (2013) Identifying the change time of multivariate binomial processes for step changes and drifts. J Ind Eng Int 9:1–11

Panagos MR, Heikes RG, Montgomery DC (1985) Economic design of x control charts for two manufacturing process models. Nav Res Logist Q. 32:631–646

Pignatiello JJ Jr, Tsai A (1988) Optimal economic design of x control charts when cost model parameters are not precisely known. IIE Trans 20:103–110

Saniga EM (1992) Robustness and flexibility of constrained economic designs: In frontiers in statistical quality control 4. Phys Verl, Heidelberg 191–200

Vommi VB, Seetala SNM (2007a) A simple approach for robust economic design of control charts. Comp Oper Res 34:2001–2009

Vommi VB, Seetala SNM (2007b) A new approach to robust economic design of control charts. Appl Soft Comput 7:211–228

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Vommi, V., Kasarapu, R.V. Economic design of control charts considering process shift distributions. J Ind Eng Int 10, 163–171 (2014). https://doi.org/10.1007/s40092-014-0086-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40092-014-0086-2