Abstract

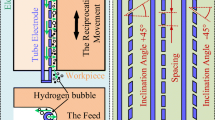

This study discusses the improvement of surface finish of medium or large holes beyond traditional drilling, boring, rough turning, or extruding by electrochemical smoothing using inserted rib-plate electrodes. High electrical current is not required when the rib plate is used to reduce the engaged area for large hole. Traditionally, the hole polishing requires a sequence of complicated premachining or scarce manual skill. In the current experiment, six types of electrode are completely inserted and connected to both continuous and pulsed direct currents. The controlled factors include the chemical composition and the concentration of the electrolyte, and the diameter of the electrode. The experimental parameters are the current density, on/off period of pulsed current, rotational speed of electrode, and the electrode geometry. For the inserted electrodes, a thin rib plate with small wedge angle towards the root of the plate provides more sufficient discharge space, which is advantageous for polishing. The electrode of single plate performs better than the double-plate electrode. The electrode of a single plate with slant discharge flute performs the best polishing effect. Pulsed direct current can slightly improve the polishing effect at the expense of increased machining time and cost. It was also found that electrobrightening after reaming or precise turning uses quite a short time to make the hole bright, and the electrochemical smoothing saves the need for reaming or precise turning, making the total process time less than the electrobrightening.

Similar content being viewed by others

References

Institute of Advanced Manufacturing Sciences (1980) Machining data handbook, 3rd edn. 2(18):11

Phillips RE (1986) What is electrochemical grinding and how does it work. Carbide Tool J 18(6):12–14

Jain VK, Pandey PC (1980) Tooling design for ECM. Precis Eng 2:195–206

McGeough JA (1974) Principles of electrochemical machining. Chapman and Hall, London

Wilson JF (1971) Practice and theory of electrochemical machining. Wiley, New York, pp 79–161

Shen WM (1995) The study of polishing of electric discharge-machined mold with ECM. MSc thesis, National Yunlin Institute of Technology, Taiwan, ROC

Rajurkar KR, Wei B, Kozak J, McGeough JA (1995) Modeling and monitoring interelectrode gap in pulse electrochemical machining. Annals CIRP 44(1):177–180

Tönshoff HK, Egger R, Klocke F (1996) Environmental and safety aspects of electrophysical and electrochemical processes. Annals CIRP 45(2):553–568

Rajurkar KR, Zhu D, McGeough JA, Kozak J, De Silva A (1999) New developments in electrochemical machining. Annals CIRP 48(2):567–579

Kashcheev VD, Merkulova NS, Davydov AD (1966) Appl Electr Phenom (5):207–214

Datta M, Landolt D (1983) Electrochemical saw using pulsating voltage. J Appl Electrochem 13(6):795–802

Kozak J, Rajurkar KR, Wei B (1994) Modeling and analysis of pulse electrochemical machining (PECM). J Eng Ind—Trans ASME 116(3):316–323

Rybalko AV, Dikusar AI (1995) Electrochemical machining with microsecond pulses. In: Proceedings of the 10th International Symposium for Electromachining (ISEM-XI), Lausanne, Switzerland, April 1995, pp 491–504

Budzynski AF (1986) Electrochemical honing-studies on shape precision of holes being processed. In: Proceedings of the 8th International Symposium for Electromachining (ISEM-8), Moscow, Russia

McGeough JA (1988) Advanced methods of machining. Chapman and Hall, London

Kozak J, Budzynski AF, Domanowski P (1998) Computer simulation of electrochemical shaping (ECM-CNC) using an universal tool electrode. J Mater Process Technol 76(1):161–164

Cagnon L, Kirchner V, Kock M, Schuster R, Ertl G, Gmelin WT, Kück, H (2003) Electrochemical micromachining of stainless steel by ultrashort voltage pulses. Z Phys Chem 217(4):299–313

Jain VK, Yogindra PG, Murugan S (1987) Prediction of anode profile in ECBD and ECD operations. Int J Mach Tools Manufact 27(1):1135–1349

Hocheng H, Pa PS (2000) Ring-form electrode in electropolishing of external cylindrical surface. Int J Electr Mach 5:7–15

Hocheng H, Pa PS (2002) Application of turning tool as electrode in electropolishing. J Mater Process Technol 120:6–12

Hocheng H, Pa PS (2003) Electropolishing of cylindrical workpiece of tool materials using disc-form electrodes. J Mater Process Technol 142(1):203–212

Hocheng H, Pa PS (2004) Design of arrow-head electrode in electropolishing of cylindrical part. Int J Mater Prod Technol 20(4):312–326

Rao SS (1996) Engineering optimization. Wiley, New York, pp 162–163

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pa, P.S., Hocheng, H. Design of rib plate of electrode in electrochemical smoothing and electrobrightening of large hole. Int J Adv Manuf Technol 34, 517–526 (2007). https://doi.org/10.1007/s00170-006-0621-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0621-4