Abstract

This paper presents an experimental investigation on feed rate [mm/min] limitations when milling free form surfaces, commonly found in dies and moulds, applying the high speed cutting technology-HSC. The results appoint feed rate as the bottleneck to achieve the real benefits of HSC in terms of machining time, surface quality and process stability. That is due to unwanted large variations on the initially programmed feed rate, mainly when milling free form surfaces. These “ups” and “downs” on feed rate result in several setbacks for the machining process itself and it can be found even when using a suitable HSC milling machine available in the market. This paper addresses some of the causes for feed rate variations and evaluates an alternative approach to describe a tool path using spline polynomial technique. In order to focus industrial applications, all equipment, materials and software used are accessible in the market. The milling experiments were accomplished on a high-speed milling machine controlled by an open architecture CNC and a high-end CAD/CAM software was used. A 3D free form workpiece was designed and a real-time monitoring system was developed to investigate the feed rate variations during milling operation. The surface quality after milling and the machine tool/CNC performance were also assessed.

Similar content being viewed by others

References

Boujelbene M, Moisan A, Tounsi N, Brenier B (2004) Productivity enhancement in dies and molds manufacturing by the use of C1 continuous tool path. I J Mach T Man 44(1):101–107

Rigby P (1993) High speed milling in the mold and die making industry. Diamond and CBN Ultrahard Materials Symposium, Ontario, Canada

Urbaniski JP, Koshy P, Dewes RC, Aspinwall DK (2000) High speed machining of moulds and dies for net shape manufacture. Mater Des 21(4):395–402

Eberlein W (1999) Modern CNC control systems for high speed machining. International Scientific Conference On Production Engineering, Opatija. pp ii108–ii121

Schulz H, Finzer TH (1999) Optimization of the cutting process using HSC in die and mold manufacturing. 5th International Scientific Conference on Production Engineering - CIM’99 Zagreb

Geist J (1999) Influence of HSC-appropriate machining parameters on NC programming. Seminário Internacional de Alta Tecnologia – Santa Bárbara, Brazil pp 57–68

Finzer TH (1998) High-speed machining (HSC) of sculptured surfaces in die and mold manufacturing. SSM 98 Sculptured Surface Machining Conference, “Machining Impossible Shapes”, Auburn Hills, MI, USA, pp 9–11

Armone A (1998) Motion control (CNC) and drive train. High performance machining. Hanser Gardner, Cininnati, OH, pp 65–116

Souza FA, Shutzer K (2001) Interpolating free form tool path for high speed cutting technology. The 7th International Scientific Conference on Production Engineering-CIM 2001. Zagreb, Croatia. Jun 2001, pp i146–i154 (in Portuguese)

LO C-C (2000) CNC machine tool surface interpolator for ball-end milling of free form surfaces. I J Mach T Man 40:307–326

Monreal M, Rodrigues CA (2003) Influence of tool path strategy on the cycle time of high-speed milling. Comp Aid Des 35:395–401

Bedworth DD, Henderson MR, Wolpe PM (1991) Computer - integrated design and manufacturing, New York

Bates C (1997) Some well-defined curves. Am Mach 141(11):51–54

Larent P, Sablonniere P (2001) Pierre Bézier: an engineer and a mathematician. Comp Aid Geom Des 18:609–617

Mahon Mc, Browne J (1993) CAD/CAM From principles to practice. Addison–Eesley, Suffolk, UK, ISBN 0-210-56502-1

Dürr H, Schünemman R (1999) Industrial aplication of new approaches of the CAD/CAM process chain for high speed machining of sculptured surfaces. International German and French Conference 2nd. Darmstadt: PTW, pp 117–120

Yau HT, Kuo MJ (2001) Nurbs machining and feed rate adjustment for high-speed cutting of complex sculptured surfaces. Int J Prod Res 39(1):21–41

Cheng M-Y, Tsai M-C, Kuo J-C (2002) Real-time NURBS command generator for CNC servo controllers. Int I J Mach T Man 42:801–813

Qui H, Cheng K, Li Y (1997) Optimal circular arc interpolation for NC tool path generation in curve contour manufacturing. Compt Aided Des 29:751–760

Koninckx B, Brussel HV (2002) Real-time NURBS interpolator for distributed motion control. CIRP 51(1):315–318

Farouki RT, Manjunathaiah J, Yan GF (1999) G codes for the specification of pythagorean- hodograph tool paths and associated feed rate functions on open-architecture CNC machines. I J Mach T Man 39(1):123–142

Tikhon M, Ko TJ, Lee SH, Kim HS (2004) NURBS interpolator for constant material removal rate in open NC machine tools. I J Mach T Man 44:237–245

Lartigue C, Thiebaut F, Maekawa T (2001) CNC tool path in terms of B-Spline curves. Compt Aided Des 33(4):307–319

Ferraz J, Oliveira JFG, Souza AF (2005) Supervision and monitoring technologies in machine tools with open architecture CNC. Congresso Brasileiro de Engenharia de Fabricação. Joinville Brazil

Ferraz F, Oliveira JFG (2005) Integration and information management in open architecture CNC’s. CIRP 55

Acknowledgements

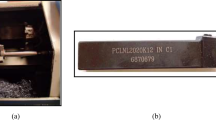

The authors thank Prof. Dr. Marcelo Teixeira dos Santos, Sociedade Educacional Santa Catarina (SOCIESC) and Laboratory for Optimization of Manufacturing Processes (OPF), from University of Sao Paulo. The authors also wish to thank Sandvik Coromant, for supplying the cutting tools used in the experiments; Unigraphics Solutions Brazil, for helping the development of the post-processor used for Spline NC code; SIEMENS and HERMLE Brazil, for all technical support; Villares Metals for supplying the rough material; and the Foundation FAPESP for supporting the HSC Thematic Project under the grant number 00/02962–4.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

de Souza, A.F., Coelho, R.T. Experimental investigation of feed rate limitations on high speed milling aimed at industrial applications. Int J Adv Manuf Technol 32, 1104–1114 (2007). https://doi.org/10.1007/s00170-006-0445-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0445-2