Abstract

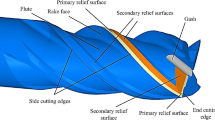

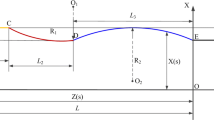

This paper presents a set of mathematical models for the design and manufacture of the helical flute and cutting-edge curve of a toroid-cone shaped revolving cutter. The study not only considers the section profile and relative feeding velocities of the grinding wheel used in the NC machining of the cutter, but also addresses the deviation of the cutting-edge curve, the residual material which exists between adjacent flutes, and the lack of cutter land. Through a process of numerical simulation, a compensation technique is developed which reduces the residual material and rebuilds the missing land. The accuracy of the theoretical models is verified by means of an experimental machining test using a WALTER CNC grinding machine. The experimental results are in good agreement with those predicted theoretically, thereby confirming the accuracy and reliability of the proposed models. This study serves as a valuable reference for researchers investigating the NC machining of cutters with special forms.

Similar content being viewed by others

References

Rodin P (1977) Fundamentals of surface forming by cutting. Kiev, Vishta Shkola

Rodin P (1966) Cutting tools. Graphical calculations and laboratory experiments, Kiev, Tehnika

Belyaev S, Gordev B (1982) Automated calculation of disk tool profile for helical surfaces. J Stanki I Instr 6:53–57

Lio HX (1993) Smooth connecting of cutting edge curve on ball-end milling cutter. Tool Eng 2:10–12

Tang YY, Chen CK, Wang S (1996) Geometry model and 2-axis NC machining of milling cutters with constant helical angle. J Harbin Inst Technol 28(5):5–7

Ya DC (1984) New manufacturing technology of conical type tool with helical groove. Tool Eng 1:1–10

Kang DC, Shiu S, Yau NS (1994) Calculation and measurement of cutting parameter of finger shape gear milling with helical groove. Tool Eng 5:15–20

Chang H, Ya DC (1997) General calculation on cutting edge of revolution tool with constant helical angle. Trans Ta-Lien Univ Technol 37(1):63–67

Hauran L (1995) Study on smooth connecting of edge curve of ball end mill. Tool Eng 29(2):11–13

Kung CH, Pin HC (1994) Broad definition and applications of helical angle. Mech Eng 1:14–15

Lio HX (1997) The forming theory and structure of edge line on revolution file with sideways knife. Tool Eng 31(2):15–16

Lio CM (1989) Calculation assistant design on molding milling cutter of end milling groove. Tool Eng 1:6–9

Lee YH, Tung YW (1987) Optimum design of cross section of end milling—a orthogonal test method. Tool Eng 11:36–38

Li LF (1995) Calculating the normal section of helical groove of milling cutter by computer. Tool Eng 5:15–19

Wu XT (1983) Machining theory of toroid-cone helical surface and it’s application. Technique Report, ChiaoTung University, His-An

Lo I (1995) Machining of cone milling using CNC machine. Tool Eng 12:14–16

Jou CH, Shen C, Wang M (1995) Study on the mathematical model of machining non-conventional form millers by NC methods. J Southeast Univ 25(2):25–29

Kung CH, Pin HC (1997) CNC grinding method of trace on cutting point and it’s application on toroid-cone shaped cutters. Tool Eng 31(9):19–24,

Tai CC, Fuh KH (1995) Model for cutting forces prediction in ball-end milling. Int J Mach Tools Manuf 35(4):511–524

Lee P, Altintas Y (1996) Prediction of ball-end milling forces from orthogonal cutting data. Int J Mach Tools Manuf 36(9):1059–1063

Yang M, Heeduck P (1991) The prediction of cutting force in ball-end milling. Int J Mach Tools Manuf 31(1):45–54

Yucesan G, Altintas Y (1996) Prediction of ball end milling forces. J Eng Ind 118(2):95–103

Sheth DS (1988) CAD software for geometry and process analysis of helical machining. Dissertation, University of Massachusetts

Altintas Y, Lee P (1996) A general mechanics and dynamics model for helical end mills. Ann CIRP 45(1):59–63

Mannan MA, Lindstrom B (1986) Performance for end mills made of different tool materials with regards to tool life and stability. Ann CIRP 35(1):37–44

Kops L, Vo DT (1990) Determination of the equivalent diameter of an end mill based on its compliance. Ann CIRP 39(1):93–96

Kang SK, Ehmann KF, Lin C (1997) A CAD approach to helical groove machining: numerical evaluation and sensitivity analysis. Int J Mach Tools Manuf 37(1):101–117

Lio CY, Lio HM (1997) Mathematical model of helical groove on toroid-cone shaped cutters. Tool Eng 34:3–6

Kang SK, Ehmann KF, Lin C (1996) A CAD approach to helical flute machining-I. Mathematical model and model solution. Int J Mach Tools Manuf 36(1):141-153

Jou CH, Ya DC, Wu XT (1991) The forming theory of special revolution tools of plane type rake face. Tool Eng 25(5):17-21

Chang JC, Shen P, Wang HC, Wu HT (1998) Machining sculptured surfaces by second order curvature cuttering. Chin J Mech Eng 34(2):87–92

Bedi S, Gravelle S, Chen YH (1997) Principal curvature alignment technique for machining complex surfaces. J Manuf Sci Eng Trans ASME 119:756–765

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hsieh, JM., Tsai, YC. Geometric modeling and grinder design for toroid-cone shaped cutters. Int J Adv Manuf Technol 29, 912–921 (2006). https://doi.org/10.1007/s00170-005-2613-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-005-2613-1