Abstract

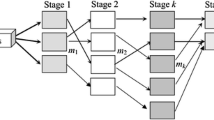

The problem of scheduling in dynamic shops is an important operational problem in view of its complexity and significance in terms of associated costs of scheduling. While a number of research studies have investigated the problem of scheduling in flow shops and job shops, only some attempts have been done to study the problem of scheduling in assembly job shops that manufacture multi-level jobs. The problem of scheduling in dynamic assembly job shops with jobs having weights for holding and tardiness of jobs deserves due attention. In this study an attempt has been made to propose new priority dispatching rules that minimize the performance measures related to weighted flowtime and weighted tardiness of jobs. The existing unweighted dispatching rules have been modified in view of the consideration of weights for flowtime and tardiness of jobs. The performances of the (modified) existing dispatching rules and the proposed dispatching rules are compared through exhaustive simulation experiments with the consideration of a number of different experimental settings involving due-date setting, utilization levels and types of job structures. The proposed dispatching rules are found to perform better than the existing ones in most experimental settings and with respect to a number of measures of performance.

Similar content being viewed by others

References

Ramasesh R (1990) Dynamic job shop scheduling: a survey of simulation research. OMEGA 18:43–56

Day JE, Hottenstein MP (1970) Review of sequencing research. Naval Research Logist Q 17:11–39

Blackstone JH, Phillips DT, Hogg GL (1982) A state of the art survey of dispatching rules for manufacturing job shop operations. Int J Prod Res 20:27–45

Haupt R (1989) A survey of priority rule based scheduling. Oper Res Spectrum 11:3–16

Holthaus O, Ziegler H (1997) Improving job-shop performance by coordinating dispatching rules. Int J Prod Res 35:539–549

Holthaus O, Rajendran C (1997) Efficient dispatching rules for scheduling in a job shop. Int J Prod Econ 48:87–105

Holthaus O, Rajendran C (2000) Efficient job-shop dispatching rules: further developments. Prod Plan Control 11:171–178

Holthaus O, Rajendran C (2002) A study on the performance of scheduling rules in buffer-constrained dynamic flowshops. Int J Prod Res 40:3041–3052

Jayamohan MS, Rajendran C (2000) New dispatching rules for job-shop scheduling: a step toward. Int J Prod Res 38:563–586

Framinan JM, Ruiz-Usano R, Leisten R (2001) Sequencing CONWIP flow-shops: analysis and heuristics. Int J Prod Res 39:2735–2749

Russell RS, Dar-el EM, Taylor BW (1987) A comparative analysis of the covert job sequencing rule using various shop performance measures. Int J Prod Res 25:1523–1540

Maxwell WL, Mehra M (1968) Multiple factor rules for sequencing with assembly constraints Naval Res Logist Q 15:241–254

Maxwell WL (1969) Priority dispatching and assembly operation in a jobshop. Rand Corporation Memorandum, RM-5370-PR

Sculli D (1980) Priority dispatching rules in job shops with assembly operations and random delays. OMEGA 8:227–234

Sculli D (1987) Priority dispatching rules in an assembly job shop. OMEGA 15:49–57

Plossl GW (1980) MRP yesterday, today and tomorrow. Prod Inv Manage, Third Q pp 1–10

Philipoom PR, Markland RE, Fry TD (1989) Sequencing rules, progress milestones and product structure in multistage job shop. J Oper Manage 8:209–229

Russell RS, Taylor BW (1985) An evaluation of sequencing rules for an assembly shop, Dec Sci 16:196–212

Goodwin JS, Goodwin JC (1982) Operating policies for scheduling assembled products. Decis Sci 13:585–603

Adam NR, Bertrand JWM, Surkis J (1987) Priority assignment procedures in multi-level assembly job shops. IIE Trans 19:317–328

Fry TD, Oliff MD, Minor ED, Leong GK (1989) The effects of product structure and sequencing rule on assembly shop performance. Int J Prod Res 27:671–686

Philipoom PR, Russell RS, Fry TD (1991) A preliminary investigation of multi-attribute based sequencing rules for assembly shops. Int J Prod Res 4:739–753

Conway RW (1965) Priority dispatching and job lateness in a job shop. J Ind Eng 16:228–237

Vepsalainen APJ, Morton TE (1987) Priority rules for job shops with weighted tardiness costs. Manage Sci 33:1035–1047

Acknowledgement

The authors acknowledge the financial support extended by Department of Science and Technology (DST), New Delhi to accomplish the research work presented in this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Natarajan, K., Mohanasundaram, K.M., Babu, B.S. et al. Performance evaluation of priority dispatching rules in multi-level assembly job shops with jobs having weights for flowtime and tardiness. Int J Adv Manuf Technol 31, 751–761 (2007). https://doi.org/10.1007/s00170-005-0258-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-005-0258-8