Abstract

Based on a recent formulation for parametric design of mechanical systems using kinematic analysis, we reported an approach to automated design by converting mechanical part geometry into a mechanism by breaking the part into sub-parts attached by higher pair joints. In order to evaluate the performance of a mechanism where a design change has been introduced into one of its links, we extend the formulation in this paper to address the propagation of this change and its effect on the velocity of other members. This analysis will limit itself to mechanisms. Velocity propagations due to modifications in the design of a mechanical part are analytically addressed using a proposed working coordinates formulation based on the cut-joint kinematic constraint method (presented earlier). Velocity vectors in state-vector notation are derived and treated as variables such that propagations of working coordinates of a link are obtained with respect to position and orientation. The underlying theory is presented and several planar and spatial mechanisms are treated.

Similar content being viewed by others

References

Abdel-Malek K, Maropis N (1998) Design-to-manufacture case study: automatic design of post-fabrication mechanisms for tubular components. J Manuf Syst 17(3):183–195

Abdel-Malek K, Zou HL, Wang JY, Othman S (1999) Automated design and parameterization of mechanical part geometry. Res Eng Des 11:206–217

Ashrafiuon H, Mani NK (1990) Analysis and optimal design of spatial mechanical systems. J Mech Transm-T ASME 112(2):200–207

Bagci C, Burke D (1993) Optimum synthesis of coupler curve and uniform rotary motion driven multiloop mechanisms generating complex output motions. J Mech Des-T ASME 115(4):967–977

Computer Aided Design Software Inc (1999) DADS user's manual. CADSI, Oakdale, Iowa

Dixit DS, Shanbhag SH, Mudur SP, Isaac K, Chinchalkar S (1999) Object oriented design of an interactive mechanism simulation system-Clodion. Comput Graph 23(1):85–94

Fung RF, Hwang CC, Huang CS (1997) Kinematic and sensitivity analyses of a new type toggle mechanism. JSME Int J C-Mech Syst 40(2):360–365

Haug EJ (1989) Computer aided kinematics and dynamics of mechanical systems, vol I. Allyn & Bacon, Boston

Hoffmann CM, Vermeer PJ (1995) Geometric constraint solving in R2 and R3. Computing in Euclidean geometry, 2nd edn. World Scientific, River Edge, New Jersey

Kang HY, Suh CH (1994) Synthesis and analysis of spherical-cylindrical (SC) link in the McPherson strut suspension mechanism. J Mech Des-T ASME 116:599–606

Liu JF, Abdel-Malek K (1999) On the problem of scheduling parallel computations of mulitbody dynamic analysis. J Dyn Syst-T ASME 121(3):370–376

Mills JK, Notash L, Fenton RG (1993) Optimal design and sensitivity analysis of flexible cam mechanisms. Mech Mach Theory 28(4):563–581

NADSdyna Core Software (2000) US national advanced driving simulator (NADS), vehicle dynamics software, release 3.0. The University of Iowa, Iowa City, IA

Watanabe K, Ichikawa K, Asano H (1993) Kinematic analysis of the constant velocity joint of the Rzeppa type. C Hen/Nihon Kikai Gakkai Ronbunshu, part C 59(560):1166–1174

Werghi N, Fisher R, Robertson C, Ashbrook A (1999) Object reconstruction by incorporating geometric constraints in reverse engineering. Comput Aided Des 31(6):363–399

Wittenburg J (1977) Dynamics of systems of rigid bodies. B.G. Teubner, Stuttgart

Wittenburg J, Wolz U (1985) MESA VERDE: a symbolic program for nonlinear articulated-rigid-body. ASME 85-DET-151

Zou HL, Abdel-Malek K, Wang JY (1996) Computer-aided-design using the method of cut-joint kinematic constraints. Comput Aided Des 28(10):795–806

Zou HL, Abdel-Malek K, Wang JY (1997) A variational approach for the design of the spatial four-bar mechanism. Mech Struct Mach 25(1):41–59

Zou HL, Abdel-Malek K, Wang J (1997) Design propagation in mechanical systems: kinematic analysis. J Mech Des-T ASME 119(3):338–345

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

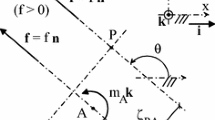

A pair of bodies i and j shown in Fig. 14 are connected by a joint. The global reference frame is xyz, the body reference frame is x'y'z', and the joint reference frame is \(x^{{\prime \prime }}_{i} y^{{\prime \prime }}_{i} z^{{\prime \prime }}_{i} \).

The position and orientation of body i is uniquely determined by vector r i and Euler parameter P i where \({\mathbf{P}}_{i} = [\begin{array}{*{20}c} {{e_{o} }} & {{{\mathbf{e}}^{T} }} \\ \end{array} ]^{T} \)and where e o and \({\mathbf{e}}^{T} = [\begin{array}{*{20}c} {{e_{1} }} & {{e_{2} }} & {{e_{3} }} \\ \end{array} ]^{T} \) are minimal representation Euler parameters specifying the orientation of link i. The transformation matrix A i , written as

where I is the identity matrix, is an orthogonal transformation matrix which transforms a vector in the body i reference frame to the global reference frame.

The position of body j can be defined with respect to body i (Fig. 4) by

where q j are the generalized coordinates. The angular velocity of body j, denoted by ω j , can be expressed as \(\omega _{j} = \omega _{i} + {\mathbf{H}}_{j} {\mathop {\mathbf{q}}\limits^\cdot }_{j} \), where the transformation matrix H j has columns that represent the axes of rotation for each component of the relative velocity vector \({\mathop {\mathbf{q}}\limits^\cdot }_{j} \) of body j with respect to body i . Differentiating Eq. 29 and combining with the equation for ω j as an augmented matrix yields

where the tilde operator (the symbol ∼) is used to denote the skew-symmetric matrix generated by the associated vector. Equation 30 written in state-vector notation is

where B j is the velocity transformation matrix, defined as \({\mathbf{B}}_{j} = {\left[ {\begin{array}{*{20}c} {{\frac{{\partial {\mathbf{d}}_{{ij}} }}{{\partial {\mathbf{q}}_{j} }} + \widetilde{{\mathbf{r}}}_{j} {\mathbf{H}}_{j} }} \\ {{{\mathbf{H}}_{j} }} \\ \end{array} } \right]}\), \(\widehat{{\mathbf{Y}}}_{j} \) is the state-vector velocity of body j, defined as \(\widehat{{\mathbf{Y}}}_{j} = {\left[ {\begin{array}{*{20}c} {{{\mathop {\mathbf{r}}\limits^\cdot }_{j} + \widetilde{{\mathbf{r}}}_{j} \omega _{j} }} \\ {{\omega _{j} }} \\ \end{array} } \right]}\), and the Cartesian velocity vector \({\mathbf{Y}}_{j} = {\left[ {\begin{array}{*{20}c} {{{\mathop {\mathbf{r}}\limits^\cdot }_{j} }} & {{\omega _{j} }} \\ \end{array} } \right]}^{T} \) can be recovered from

where the transformation matrix \({\mathbf{T}}_{j} = {\left[ {\begin{array}{*{20}c} {{\mathbf{I}}} & {{ - \widehat{{\mathbf{r}}}_{j} }} \\ {{\mathbf{0}}} & {{\mathbf{I}}} \\ \end{array} } \right]}\).

1.1 Variational form of the position and velocity state-vectors

We define the term working coordinates (denoted by wc) as the position and orientation of the link that is permitted to undergo design changes denoted by r wc and P wc, respectively. Changes in \({\mathbf{s}}^{\prime }_{{ij}} \) and P ij affect the kinematic relations between bodies and influence the dynamic characteristics of the underlying mechanism. The goal of the derivation in this section is to obtain the variational position and velocity state vectors. To derive the general design propagation equations, the variations of Eq. 29 are determined as

and the virtual rotation vector as

where the global vector δπ, is the virtual rotation of the transformation matrix A from the body reference frame x'y'z' to the global reference frame xyz and \(\delta \widetilde{{\mathbf{\pi }}}\) is its skew symmetric matrix defined as \(\delta \widetilde{{\mathbf{\pi }}} = \delta {\mathbf{AA}}^{T} \) and E ij is the Euler parameter semi-rotation matrix such that

In state-vector notation, Eqs. 33 and 34 are written as

where \(\delta \widehat{{\mathbf{z}}}_{j} = {\left[ {\begin{array}{*{20}c} {{\delta {\mathbf{r}}_{j} + \widetilde{{\mathbf{r}}}_{j} \delta {\mathbf{\pi }}_{j} }} \\ {{\delta {\mathbf{\pi }}_{j} }} \\ \end{array} } \right]}\) \({\mathbf{M}}_{i} = {\left[ {\begin{array}{*{20}c} {{{\mathbf{A}}_{i} }} \\ {{\mathbf{0}}} \\ \end{array} } \right]}\) and \({\mathbf{N}}_{j} = {\left[ {\begin{array}{*{20}c} {{\widetilde{{\mathbf{r}}}_{j} - \widetilde{{\mathbf{d}}}_{{ij}} }} \\ {{\mathbf{I}}} \\ \end{array} } \right]}\). To transform to Cartesian coordinates, the relationship between the variational position state-vector \(\delta \widehat{{\mathbf{z}}}_{j} \) and variational position vector δz j is \(\delta {\mathbf{z}}_{j} = {\mathbf{T}}_{j} \delta \widehat{{\mathbf{z}}}_{j} \) where T j is defined in Eq. 32. Taking the variation of Eq. 5, the variational velocity state-vector is obtained as

where

The relationship between the variational velocity state-vector and the variational velocity vector is

where \(\delta {\mathbf{Y}}_{j} = [\begin{array}{*{20}c} {{\delta {\mathop {\mathbf{r}}\limits^\cdot }_{j} ^{T} }} & {{\delta \omega _{j} }} \\ \end{array} ]^{T} \) and \({\mathbf{Q}}_{j} = - \delta {\mathbf{T}}_{j} \widehat{{\mathbf{Y}}}_{j} = [\begin{array}{*{20}c} {{\delta \widetilde{{\mathbf{r}}}_{j} \omega _{j} }} & {{\text{0}}} \\ \end{array} ]^{T} \) The above formulation will be used to obtain the kinematic sensitivity of propagated changes in design variables.

Rights and permissions

About this article

Cite this article

Abdel-Malek, K., Yang, J. The method of cut-joint kinematic constraint: velocity propagations. Int J Adv Manuf Technol 31, 815–824 (2007). https://doi.org/10.1007/s00170-005-0246-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-005-0246-z