Abstract

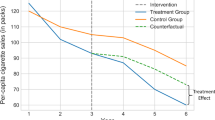

The observations from the process output are always assumed independent when using a control chart to monitor a process. However, for many processes the process observations are autocorrelated. This autocorrelation can have a significant effect on the performance of the control chart. This paper considers the problem of monitoring the mean of a quality characteristic X on the first process step and the mean of a quality characteristic Y on the second process step, in which the observations X can be modeled as an AR(1) model and observations Y can be modeled as a transfer function of X since the state of the second process step is dependent on the state of the first process step. To effectively distinguish and maintain the state of the two dependent process steps, the Shewhart control chart of residual and the cause-selecting control chart are proposed. The proposed control charts’ performance is measured by the rate of alarm on the proposed charts. From numerical analysis, it shows that the performance of the proposed control charts is much better than the misused Hotelling T2 control chart and the individual Shewhart X and Y control charts.

Similar content being viewed by others

References

Shewart W (1931) Economic control of quality of manufactured product. Van Nostrand, Princeton, NJ

Abraham B, Kartha CP (1979) Forecast stability and control charts. ASQC Tech Conf Trans, Am Soc Qual Control, pp 675–685

Alwan LC (1991) Autocorrelations: fixed and versus variable control limits. Qual Eng 4:167–188

Alwan LC, Roberts HV (1988) Time-series modeling for statistical process control. J Bus Econ Stat 6:87–95

Berthouex PM, Hunter WG, Pallesen L (1978) Monitoring sewage treatment plants: some quality control aspects. J Qual Technol 10:139-149

Dooley KJ, Kapoor SG, Dessouky MI, Devor RE (1986) An integrated quality systems approach to quality and productivity improvement in continuous manufacturing processes. Trans ASME J Eng Ind 108:322–327

Delves LM, Mohamed JL (1985) Computational methods for integral equations. Cambridge University Press, New York

Ermer DS (1980) A control chart for dependent data. ASQC Tech Conf Trans Am Soc Qual Control, pp 121–128

Harris YJ, Ross WH (1991) Statistical process control procedures for correlated observations. Can J Chem Eng 69:48–57

Montgomery DC (2001) Introduction to statistical quality control, 3rd edn. Wiley, New York

Montgomery DC, Mastrangelo CM (1991) Some statistical process control methods for autocorrelated data. J Qual Technol 23:179-193

Wardell DG, Moskowitz H, Plante RD (1992) Control charts in the presence of data correlation. Manage Sci 38:1084–1105

Wardell DG, Moskowitz H, Plante RD (1994) Run length distributions of special-cause control charts for correlated processes. Technometrics 36:3–17

Longnecker MT, Ryan TP (1992) Charting correlated process data. Technical Report No.166. Department of Statistics. Texas A & M University. Collage Station, TX

Yashchin E (1993) Performance of CUSUM control schemes for serially correlated observations. Technometrics 35:37–52

Kramer H, Schmid W (1997) Control charts for time series. Nonlinear Anal 30:4007–4016

Schmid W (1995) On the run length of a Shewhart chart for correlated data. Stat Papers 36:111–130

Lin WS, Adams BM (1996) Combined control charts for forecast-based monitoring schemes. J Qual Technol 28:289–301

Schmid W (1997a) CUSUM control schemes for Gaussian processes. Stat Papers 38:191–217

Padgett CS, Thombs LA, Padgett, WJ (1992) On the α-risks for Shewhart control charts. Commun Stat-Simul Comput 21:1125–1147

Runger GC, Willemain TR, Prabhu S (1995) Average run lengths for CUSUM control charts applied to residuals. Commun Stat-Theory Methods 24:273–282

Vander Well SA (1996) Modeling processes that wander using moving average models. Technometrics 38:139–151

Timmer DH, Pigantkiello JJ, Longnecker M (1998) The development and evaluation of CUSUM-based control charts for an AR(1) process. IIE Trans 30:525–534

Schmid W (1997b) On EWMA charts for time series, in Frontiers of statistical quality control. In: Lenz HJ, Wilrich P-T (eds) Physica-Verlag, Heidelburg

Zhang NF (1997) Detection capability of residual control chart for stationary process data. J Appl Stat 24:363–380

Schmid W, Schone A (1997) Some properties of the EWMA control chart in the presence of autocorrelation. Ann Stat 25:1277–1283

Alwan LC, Radson D (1992) Time-series investigation of subsample mean chart. IIE Trans 24:66–80

Lu C, Reynolds M (1999) EWMA control charts for monitoring the mean of autocorrelated processes. J Qual Technol 31:166–188

Zhang G (1984) A new type of control charts and a theory of diagnosis with control charts. World Qual Congress Trans, Am Soc Qual Control, pp 75–85

Wade R, Woodall W (1993) A review and analysis of cause-selecting control charts. J Qual Technol 25:161–169

Yang S (1997) The economic design of control charts when there are dependent process steps. Int J Qual Reliab Manage 14:606–615

Yang C (1999) Economic process management and its application on bank industry. Qual Quant 31:381–394

Yang S (2003) Optimal processes control for a failure mechanism. Commun Stat 4:1285–1314

Yang S (2003) Dependent processes control for over-adjusted process means. Int J Adv Manuf Technol (in press)

Yang S, Chen Y (2003) Processes control for two failure mechanisms. J Chin Inst Ind Eng 20:481–493

Box G, Jenkins G, Reisel G (1994) Time series analysis, forecasting and control. Prentice-Hall, Englewood Cliffs, NJ

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, SF., Yang, CM. An approach to controlling two dependent process steps with autocorrelated observations. Int J Adv Manuf Technol 29, 170–177 (2006). https://doi.org/10.1007/s00170-004-2490-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-004-2490-z