Abstract

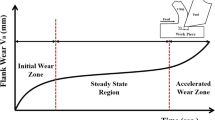

The conventional methods of tool life estimation take a long time and consume a lot of work piece material. In this paper, a quicker method for the estimation of tool life is proposed, which requires less consumption of work piece material and tools. In this method the tool life is estimated by fitting a best-fit line on the data falling in the steady wear zone and finding the time till tool failure by extrapolation. Neural networks are used to predict lower, upper and most likely estimates of the tool life. Comparison between neural networks and multiple regression shows the superiority of the former. The paper also proposes a methodology for continuous monitoring of tool use in the shop floor and updating/obtaining the tool life estimates based on the shop floor feed back.

Similar content being viewed by others

References

Gilbert WW (1950) Economics of machining: machining theory and practice. American Society of Metals, Cleveland, OH

Ermer DS (1971) Optimization of constrained machining economics problem by geometric programming. Trans ASME J Eng Ind 93:1067–1072

Petropoulos PG (1973) Optimal selection of machining rate variables by geometric programming. Int J Prod Res 11(4):305–314

Lambert BK, Walvekar AG (1978) Optimization of multipass machining operations. Int J Prod Res 16(4):259–265

Shin YC, Joo YS (1992) Optimization of machining condition with practical constraints. Int J Prod Res 30(12):2907–2919

Kee PK (1996) Development of constrained optimization analysis and strategies for multipass rough turning operations. Int J Mach Tools Manuf 36(1):115–127

Gupta R, Batra JL, Lal GK (1995) Determination of optimal subdivision of depth of cut in multipass turning with practical constraints. Int J Prod Res 33(9):2555–2565

Chen MC, Tsai DM (1996) A simulated annealing approach for optimization of multipass turning operation. Int J Prod Res 34(10):2803–2825

Liang M, Mgwatu M, Zuo M (2001) Integration of cutting parameter selection and tool adjustment decisions for multipass turning. Int J Adv Manuf Technol 17:861–869

Onwubolu GC, Kumalo T (2001) Optimization of multipass turning operations with genetic algorithm. Int J Prod Res 39(16):3727–3745

Al-Ahmari AMA (2001) Mathematical model for determining machining parameters in multipass turning operations with constraints. Int J Prod Res 39(15):3367–3376

Baykasoglu A, Dereli T (2002) Novel algorithm approach to generate the ‘number of passes’ and ‘depth of cuts’ for the optimization routines of multipass machining. Int J Prod Res 44(7):1549–1565

Wu SM (1964) Tool life testing by response surface methodology-part 1. Trans ASME J Eng Ind 86:105–110

Wu SM (1964) Tool life testing by response surface methodology-part 2. Trans ASME J Eng Ind 86:111–116

Vilenchich R, StrobeleK, Vebter R (1962) Tool life testing by response surface methodology coupled with a random strategy approach. Proc, 13th Int MTDR Conference. Birmingham, UK, pp 261–266, September 1962

Ezugwu EO, Arthur SJ, Hines EL (1995) Tool wear prediction using artificial neural networks. J Mater Process Technol 49:255–264

Tosun N, Özer L (2002) A study of tool life in hot machining usingartificial neural networks and regression analysis methods. J Mater Process Technol 124:99–104

Dos Santos ALB, Duarte MAV, Abrato AM, Machado AR (1999) An optimization procedure to determine the coefficient of the extended Taylor’s equation in machining. Int J Mach Tools Manuf 39:17–31

Axinte DA, Belluco W, De Chiffre L (2001) Reliable tool life measurements in turning – an application to cutting fluid efficiency evaluation. Int J Mach Tools Manuf 41:1003–1014

Armarego EJA, Jawahir IS, Osfaviev VA, Patri VK (1996) Modeling of machining operations. In working paper STC ‘C’ working group. Hallway Publishers, Paris, France

Stephenson DA, Agapiou JS (1997) Metal cutting theory and practice. Dekker, New York

Hegginbotham WB, Pandey PC (1967) A variable rate machining test for tool life evaluation. Proc, 8th International MTDR conference, Manchester, September 1967

Kohli A, Dixit US (2004) A neural network based methodology for prediction of surface roughness in turning process. Int J Adv Manuf Technol (online first)

Dieter GE (1991) Engineering design: a materialistic and processing approach, 2nd edition. McGraw-Hill, New York

Ishibuchi H, Tanaka H (1991) Regression analysis with interval model by neural networks. Proc IEEE Int Joint Conf on Neural Networks. Singapore, pp 1594–1599

Rao SS (1996) Engineering optimization: theory and practice, 3rd edition. New Age International, New Delhi

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ojha, D., Dixit, U. An economic and reliable tool life estimation procedure for turning. Int J Adv Manuf Technol 26, 726–732 (2005). https://doi.org/10.1007/s00170-003-2049-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-003-2049-4