Abstract

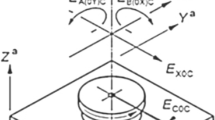

Current five-axis machining path planning is based on cutter location points, and only the scallop height of the points are calculated roughly to evaluate the planning precision, but the height of the scallop formed in the whole movement of the cutter can’t be calculated effectively, therefore, the machining precision can’t be controlled reasonably. This paper presents a new method to calculate the scallop height of the whole movement of the cutter and control the machining precision, which derives a five-axis machining cutter movement envelope equation, calculates the intersection of the cutter enveloping surfaces of adjacent paths to acquire the scallop curve and calculates the distance from the curve to the design surface to acquire the maximal height. Based on the method, the precision evaluation can be realized accurately and the machining precision can be controlled effectively by adjusting the cutter pose and optimizing the machining path interval.

Similar content being viewed by others

References

Choi BK, Lee CS, Hwang JS et al. (1988) Compound surface modelling and machining. Comput Aided Des 20:127–136

George KK, Ramesh Babu N (1995) On the effective tool path planning algorithms for sculptured surface manufacture. Comput Ind Eng 28:823–838

Chen T, Ye P (2002) A tool path generation strategy for sculptured surface machining. Mater Process Technol 127:369–373

Roth D, Bedi S, Ismail F, Mann S (2001) Surface swept by a toroidal cutter during 5-axis machining. Comput Aided Des 33:57–63

Sheltami K, Bedi S, Ismail F (1998) Swept volumes of toroidal cutters using generating curves. Mach Tools Manuf 38:855–870

Blackmore D, Leu MC, Wang LP (1997) The sweep-envelope differential equation algorithm and its application to NC machining verification. Comput-Aided Des 29:629–637

Feng DK, Ma XF (1994) Envelope principle and its application on mechanics. China Metallurgy Industry Press, Beijng, China, in Chinese

Su BQ (1988) Differential geometry. Higher Education Press, Beijing, China, in Chinese

Su BQ, Liu DY (1981) Computation geometry. Shanghai Scientific & Technical Publishers, Shanghai, China, in Chinese

Bajaj CL, Hoffmann CM, Lynch RE, Hopcroft JEH (1988) Tracing surface intersections. Comput Aided Geom Des 5:285–307

Barnhill RE, Kersey SN (1990) A marching method for parametric surface/surface intersection. Comput Aided Geom Des 7:257–280

Heo H-S, Kim M-S, Elber G (1999) The intersection of two ruled surfaces. Comput Aided Des 31:33–50

Ye X, Maekawa T (1999) Differential geometry of intersection curves of two surfaces. Comput Aided Geom Des 16:767–788

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, Yf., Li, B. & Yan, Sj. Research on the method of precision evaluation and controlling for the cutter location path in five-axis machining. Int J Adv Manuf Technol 26, 342–350 (2005). https://doi.org/10.1007/s00170-003-1992-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-003-1992-4