Abstract

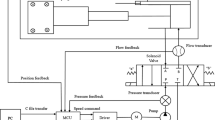

In order to produce precise injection moulding products, a closed-loop controller is employed instead of the open-loop control of a traditional injection moulding machine for monitoring the filling and post-filling phases of the injection processes. Since the injection moulding system has complicated and variable dynamics, the classical control theory is difficult to implement for the precise injection moulding processes. Here, two intelligent neural network control strategies are employed to adjust the injection speed of the filling phase and control the nozzle pressure of the post-filling phase. Since the neural controller has learning ability to track the variation of the injection processes, this control strategy has the advantages of adaptivity and robustness for general purpose application to an injection moulding machine. The experimental results show that this controller has good performance in the actual injection moulding processes.

Similar content being viewed by others

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, SJ., Lee, TH. Application of Neural Networks in Injection Moulding Process Control . Int. Journ. Adv. Manufac. Tech. 21, 956–964 (2003). https://doi.org/10.1007/s00170-002-1417-9

Issue Date:

DOI: https://doi.org/10.1007/s00170-002-1417-9