Abstract

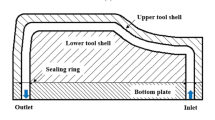

This study is on the finite element and abductive network method application to die-casting dies with free-form surfaces. The study aims to find the optimal cooling system parameters and decrease in deformation of a die-casting die. In order to avoid the numerous influencing factors, the free-form surface of a die-casting die is created as a non-linear Eq. of a polynomial function. The parameters of the cooling system, including the channel space and channel diameter, are adjusted according to the non-linear Eq.. An abductive network has been built for modelling the die-casting cooling parameters. The abductive network is composed of a number of functional nodes. Once the cooling system parameters are given, this network can predict the deformation of the die-casting accurately. A simulated annealing optimisation algorithm with a performance index is then applied to the neural network for searching for the optimal cooling system parameters and to obtain a satisfactory result.

Similar content being viewed by others

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, J. The Optimal Design of a Cooling System for a Die-Casting Die With a Free Form Surface . Int. Journ. Adv. Manufac. Tech. 21, 612–619 (2003). https://doi.org/10.1007/s00170-002-1331-1

Issue Date:

DOI: https://doi.org/10.1007/s00170-002-1331-1