Abstract

The novelty of additive manufacturing (AM) involves new requirements, restrictions and rules, that are considerably different to those of conventional manufacturing methods. Therefore, designers often lack experience and knowledge about identifying AM-suited components. However, to ensure profitability, it is essential to choose components, that are well suited for additive manufacturing. State-of-the-art user-support methods for identifying AM potential widely focus on either economic potential or manufacturability but fail to address both aspects. While machine learning solutions are considered highly efficient, the assessment outcome lacks process transparency, inhibiting troubleshooting, plausibility checks and problem-oriented considerations. This paper proposes a holistic, yet detailed and transparent approach to identify conventionally manufactured parts for AM from an existing product portfolio, enabling decision-making based on quantifiable results. It combines and advances state-of-the-art methods, considering manufacturability, economic profitability and socio-ecological aspects. Besides evaluating AM potential, the method additionally assesses the components' potential for re-design-based enhancement for AM suitability. Besides understanding product functions and present production processes, users are expected to have a basic understanding of company goals. The approach involves inquiries regarding company- and product-specific priorities, enabling a weighted assessment. The weights are determined based on individual company philosophies regarding AM value propositions such as differing stakeholder interests and priorities. Additionally, the approach allows users to investigate different development goals by weighting opportunistic and restrictive assessment. The method application is demonstrated via an assembly comprising 11 parts in a scenario focusing on serviceability, eventually determining suitability statements.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

An increasing number of companies are eager to incorporate additive manufacturing (AM) in their production processes, as AM bears outstanding potential for obsolescence management, functional integration and spare part supply in cases of end-of-service scenarios. Besides high initial investments, lacking knowledge regarding AM-specific requirements, restrictions and rules still play a significant role in hesitation towards AM. Since AM production costs (e.g., powder costs, machine costs) constantly declined over the past decade, solutions to compensate AM knowledge deficits should be addressed.

It is challenging to maintain an overview of the new possibilities and restrictions in this new field of technology, especially because possibilities and restrictions in AM deviate substantially from those in the conventional manufacturing processes. Identifying and (re-)designing parts, originally designed for subtractive production processes, present a major challenge for less-experienced users. For this reason, it is useful to include tools which assist designers in working with this new technology. Worksheets, automatized filter algorithms, workshops or databases filled with information or inspiration are conceivable tools. Dependent on varying boundary conditions, some approaches are more suitable than others, which will be further analyzed in Sect. 3.1.

The proposed method supports users in choosing AM-suited parts from an existing product portfolio, enabling a decision-making process based on a quantifiable approach. It covers a wide range of relevant aspects for decision-making, including opportunistic and restrictive approaches. Besides assessing the AM potential, the proposed method additionally considers potential geometric adaptations that might increase AM suitability, especially for components with low AM potential.

2 State-of-the-art

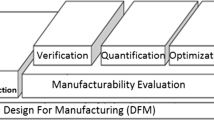

This section presents a brief overview of prior findings related to this work. The present paper introduces an AM assisting tool, and hence, the examined literature is required to place a focus on this topic as well. Kumke et al. (2017), referring to Laverne et al. (2015), further distinguish opportunistic from restrictive approaches. Focusing on design for additive manufacturing (DFAM), the opportunistic approaches within Kumke et al. (2017) emphasize design freedom enabled by AM. Accordingly, the restrictive approach addresses limitations caused by AM, mainly by defining “design rules that ensure manufacturability” (Kumke et al. 2017).

The following Sects. 2.1, 2.2 and 2.3 examine the literature regarding restrictive approaches, opportunistic approaches and combinations of both. Tables 1, 2 and 3 provide an overview of the discussed works, considering respective AM technologies, i.e., material extrusion (MEX), vat photopolymerization (VPP), and powder bed fusion (PBF). They summarize the literature of the respective subsection and identify correspondent shortcomings.

2.1 Restrictive approach

Simple, yet effective AM applicability validation tools for manageable batch sizes are worksheets. The assessment can be done by rating properties (e.g., material removal, overhangs, self-supporting angles) as described by Booth et al. (2017) and Bracken et al. (2020). The “Geometry for Additive Part Selection (GAPS) Worksheet” in Bracken et al. (2020) is based on the “Design for Additive Manufacturing Worksheet” in Booth et al. (2017); consequently, both worksheets work similarly: the examined properties are manually rated between 1 and 5. Eventually, the scores are summed up to a total score. Both worksheets give a final statement on AM suitability including a recommendation for action (i.e., “needs redesign” or “AM not recommended”). Additionally, certain properties (e.g., low production complexity) are regarded as particularly critical. Given one of these critical properties is rated with the lowest possible score of 1, users are immediately advised against AM, regardless of the total score. While Booth et al. (2017) mainly focus on properties addressing production processes (e.g., production complexity or material removal), Bracken et al. (2020) focus on geometric features (e.g. overhangs, pocket size, etc.).

Ley et al. (2017) introduce an automatized filter system, which can analyze a company’s entire product portfolio and identify AM-suited parts. The approach is a multi-step filter, examining several properties (e.g., legal aspects, complexity or feasibility of the conventional production process). Nevertheless, this method fails to address the additive manufacturability of the part, except for inspecting part dimensions to fit the part into the build space. Only if all requirements are fulfilled, a part will be considered as a potential AM part. The algorithm presented by Kim et al. (2019) is an ontology-based multi-step filter, where four aspects (geometry, clearance, overhangs and support structure) are examined. Every step either returns the feedback “manufacturable” or, if the part is not manufacturable, a precise design recommendation to enhance AM suitability. The approach of Ley et al. (2017) considers a wider range of AM-affecting aspects than Kim et al. (2019). However, Ley et al. (2017) merely identify AM-suited parts by classifying the parts into “suitable for AM” and “not suitable for AM”. The approach of Kim et al. (2019), on the contrary, strives to obtain AM-suited parts by additionally proposing design modification suggestions in case of a negative assessment outcome.

Lu (2016) introduces a “3D Printability Checker” based on machine learning (ML) algorithms. 3D CAD models are automatically analyzed and feedback of either “printable” or “not printable” is given to the user. It does not become apparent, how (e.g., based on which parameters and thresholds) the outputs are generated, which is typical for ML applications. Mayerhofer et al. (2021) propose a method to automatically analyze the additive manufacturability of designed parts. The backend is primarily based on two components. First, knowledge about AM materials, processes and manufacturability requirements is managed ontology based. Second, a mesh analyzer automatically inspects the parts for critical geometries (e.g., wall thickness, gap width, overhangs, inner or outer radii), based on the saved knowledge.

2.2 Opportunistic approach

While the previously mentioned tools emphasize restrictive aspects, Bin Maidin et al. (2012) focus on the opportunistic perspective. The “design feature database” inspires designers and outlines the possibilities that AM implies, by providing design features from different industries. The features are assigned to corresponding applications (e.g., weight reduction, dual material features, internal structures) and reasons for AM usage (e.g., functionality improvement, aesthetics, parts consolidation). Besides differentiating between opportunistic and restrictive approaches, Kumke et al. (2017) provide a broad overview of opportunistic AM potentials with a semantic network, e.g., several kinds of complexity, higher/additional product value or cost reduction. Additionally, further DFAM methods and tools are developed, such as a case study collection or physical models for AM design potentials.

Ahtiluoto et al. (2019) merely focus on a weighted assessment by comparing additive manufacturing to the conventional manufacturing in terms of product performance, manufacturing speed and part cost. Concerning manufacturing speed and part cost, the design process and production process are considered. The weighted assessment allows individual customization of the evaluation process. In contrast, Schneck et al. (2019) propose a method, which includes a wider range of assessment criteria. Initially, Schneck et al. (2019) categorize the identified opportunistic aspects into “enablers” and “objectives”. Enablers directly address technological aspects (e.g., manufacturing process, functional integration, reduction of component mass) and result in corresponding objectives. The said objectives describe beneficial aspects, which have a positive effect on the business case in general (e.g., lead time, logistics, maintenance). Additionally, enablers and objectives are categorized into four levels: product, process chain, life cycle and company.

Winkler et al. (2020) identify part complexity as the “most important factor in the decision for AM” when it comes to an opportunistic approach and focuses on this attribute. The complexity of CAD files is analyzed using a decision tree and an artificial neural network while making use of Data Mining. Both tools classify analyzed parts into two classes: “complexity supports AM” and “complexity does not support AM”. Yang et al. (2020) focus on opportunistic aspects in general. Utilizing a combination of automatically imported CAD data for geometric information and manually imported information on further model features and economic aspects, the introduced ML-based software can provide potential scores about certain AM potentials (e.g., lightweight, part consolidation, internal channel, customization and economic potential).

Molina et al. (2022) introduce a part identification method for assemblies suited for part consolidation and functional integration. The method is developed in an adaptation scenario (see Sect. 3.1.3) with the aim of redesigning components. This approach identifies parts based on specific indicators, which point out parts with a high AM potential, i.e., aspects regarding performance-oriented design, on-demand-manufacturing and integrated design.

Nevertheless, the scope of this work is set around the approach of directly replacing currently conventionally manufactured parts in a service scenario context. Part geometries and functionality are not supposed to be changed excessively due to compatibility reasons within this AM design approach (see Sect. 3.1.3). Therefore, design optimization and redesign approaches are not the main focus of this literature review.

2.3 Combined opportunistic and restrictive approach

Knofius et al. (2016) introduce a weighted ranking method, which considers both opportunistic and restrictive aspects. The first part of this method is an exclusion criteria filter. Components which do not fulfil basic requirements are detected and excluded from further inspections. This filter is kept very simple, since the goal of this method is to scan a large number of parts in a short time. AM-specific geometric restrictions (minimum wall thickness, maximum hole diameters, etc.) are not considered by this filter. Afterwards, the prefiltered components are rated based on a weighted ranking system. The ranking attributes can be associated with different company goals. Based on the priority of the companies and respective associations, the attributes are weighted individually. The company priorities are determined with a “pairwise comparison following the analytical hierarchy process” (Knofius et al. 2016). Leutenecker-Twelsiek (2019) proposes a very brief, yet comprehensive rating tool. The final score includes weighted ratings of technological feasibility, post-processing effort, user benefit and OEM benefits, utilizing a rating range of 0 (negative impact) to 5 (very positive impact). The weights can be individually adjusted according to use case needs. The final score places a special focus on user and OEM benefits by including an additional separately adjustable addend containing a repetition of these two aspects.

Lindemann et al. (2015) propose a method, which aims to support users in identifying parts from the existing company portfolio, that are most suited to undergo an AM optimizing redesign process. First, potential transformation parts of the companies’ product portfolio are identified within a brainstorming workshop, which results in a list of potential parts. Next, the parts on this list are rated using the “Trade-off-Methodology (TOM) Matrix”. This TOM Matrix is a multiple-step rating system, where the previously identified parts are narrowed down to no more than three parts. Kruse et al. (2017) modify the TOM Matrix by integrating questionnaires. The first questionnaire deals with company strategy orientation and the second with development goals. The questionnaires are filled manually by a company member. Based on these questionnaires, a TOM Matrix expert adjusts the TOM Matrix weights before both experts complete the TOM Matrix by answering the final questions together (Kruse et al. 2017).

Ghiasian et al. (2018) present a framework to evaluate AM feasibility compared to the conventional manufacturing methods, including opportunistic and restrictive aspects, which is developed for FDM technology. The first filter identifies critical areas (e.g., thin walls, bores, small gaps) using a voxel-based approach for geometry evaluation. Next, a second filter approximates the optimum orientation of the part in the build space, by minimizing the required support structure. Finally, the third filter executes and evaluates a resource estimation regarding time and cost, based on the previously collected data. Moreover, Ghiasian and Lewis (2022) introduce a fully automated component assessment utilizing the approach introduced by Ghiasian et al. (2018). This approach additionally includes an ML-based inspection of potential geometric adaptations and an automated redesign process, which provides AM-optimized STL files as final output.

Bracken Brennan et al. (2021) propose a comprehensive and general multi-step method. The initial goal is to consider a maximum number of relevant features while keeping the method as general as possible. The approach is not limited towards specific design situations or AM production processes. It considers restrictive and opportunistic aspects and allows users to incorporate quotes, when available, while not necessarily requiring them.

Page et al. (2019) introduce a machine learning-based “semi-automated decision support system (DSS)”. The DSS supports users in evaluating AM suitability of a traditionally manufactured part, observing opportunistic and restrictive aspects. The restrictive assessment solely considers economic feasibility, and the opportunistic assessment evaluates six types of AM potentials (e.g., light weighting customization, part consolidation). The economic feasibility is evaluated automatically, based on enterprise resource planning (ERP) system data. The AM potential analysis is mainly based on user inputs.

2.4 Research needs

It becomes apparent that a majority of existing rating tools either focus on opportunistic approaches or emphasize a restrictive perspective. Research that takes both points of view into account is kept very simple and solely considers a relatively limited number of aspects. Further, weighted rating tools do not take differentiating stakeholder interests into account.

In general, state-of-the-art rating solutions are limited towards specific aspects and fail to highlight the overall picture. Especially for a first assessment of general AM potential, a broad but traceable assessment is necessary to enable well-informed decisions about further proceedings. As most evaluation methods focus on scenarios, where the parts are rated after an AM-adapted (re-)design, they do not take potential geometric adjustments into account, which could elevate the AM potential scores with very little design effort (referred to as AM adaptation potential). Assessments considering potential design changes and having recommendations made follow very heuristic approaches. None of the state-of-the-art approaches considers differing stakeholder interests and importance, especially regarding opportunistic aspects.

This research aims to develop a comprehensive yet easy-to-operate method, which assesses opportunistic and restrictive aspects of its rating system. It should be possible to include different stakeholder interests. Additionally, the results of the restrictive assessment should be examined towards conceivable adjustments, highlighting potential quick and effective geometric adjustments towards AM suitability.

3 Comprehensive rating method

The following section outlines the proposed rating method. First, the scope of the application is illustrated while clearly defining the present scenario. Next, the accordingly developed assessment process is introduced in detail. Finally, assumptions made throughout the assessment process and usage instructions are introduced.

The concept and terminology of “restrictive” versus “opportunistic” approaches by Kumke et al. (2017) were adopted for this work. The opportunistic approach is expanded by adding further benefits caused by AM (e.g., economic, ecological or efficiency aspects) besides benefits on the design/functionality level. The restrictive approach additionally considers further counterproductive or limiting impacts (e.g., standardization level, conventional production effort or legal aspects). Kumke et al. (2016) distinguish between three approaches for integrating the existing tools and methods, i.e., “type 1: direct integration of general design methods and tools”, “type 2: direct integration of DFAM-specific approaches” and “type 3: synthesis of similar DFAM approaches”. The proposed method is based on the approach of type 3, aiming to combine several approaches with similar objectives, extended with the addition of a novel aspect of considering potential adaptations (see Sect. 3.2.3).

3.1 Scope of application

Depending on the overall situation (e.g., production method, design approach etc.), the focus of a potential assessment should differ. Therefore, the following scope of application was chosen and defined beforehand.

3.1.1 General assumptions

The proposed method is developed with a focus on powder bed fusion (PBF) processes. Nevertheless, it could be applicable in the context of other AM technologies too, depending on restrictions and thresholds of respective production processes.

For a meaningful geometric assessment, the part orientation within the build space must be set in advance. Further, it is assumed that there have not been any standard AM adaptations made beforehand (e.g., rounding edges). For this reason, these properties are not examined within the assessment. These standard adaptations are expected to be performed after the assessment, followed by simulations and tests on load capacity, before entering prototyping or even production processes.

Target users are designers and all kinds of employees working on product planning processes, interested in utilizing AM, despite having comparably little AM knowledge. Even though users are not expected to be AM experts, they should have acquired a basic understanding of AM processes and problems or difficulties that might occur when working with AM (e.g., the overhang issue or the support structure topic). It is expected that users have satisfactory knowledge about product/part requirements, the (original) production process and ideally a basic understanding of the company goals, strategy or vision. In case of lack of the afore-described competences, the information/data inputs should be split up between divisions.

Figure 1 proposes the assumed usual workflow for AM conception processes. If the parts of interest already concern a manageable number of components, the first step of the process can be skipped. This paper focuses on the second step of the proposed process, the identification of high potential conventionally manufactured parts for additive manufacturing from the existing product portfolio.

3.1.2 Mindset based on product development trigger

Based on the initial reason for adjusting current production processes (hereafter referred to as “development triggers”), the mindset in the development process differs. Figure 2 provides an overview of conceivable triggers for incorporating AM, exemplary use cases and the resultant mindsets of either “minimize effort” or “higher efforts tolerated”.

The triggers can be categorized according to their origin, meaning either company-external or -internal. External triggers usually require a reaction based on minimum effort, as the main goal is an unintended, but necessary adoption to a changing environment. Furthermore, triggers can be classified according to the level they occurred on, in particular on the product level or strategy level (i.e., higher management). In most cases, triggers on strategy level will require rigorously narrowing down potential products/components from the entire product portfolio, before moving over to a more detailed examination afterwards. In contrast, a trigger on the product level allows the user to immediately carry out a more detailed analysis of the components, as the number of parts is already limited from the beginning. Depending on the mindset, certain aspects will be more or less important to be rated during a potential assessment.

The proposed method is developed with a “minimize effort” mindset, initiated by an internal development trigger on the product level. The initial consideration was the potential occurrence of an End of Service scenario.

3.1.3 AM design approach

Diegel et al. (2019) distinguish between three AM design approaches: direct part replacement, adapt for AM and design for AM.

Figure 3 provides an overview of all three design approaches, additionally addressing the consequences, the approaches have on design and production processes. The direct part replacement approach solely modifies the production process, the form of the part must not be changed (Diegel et al. 2019). This approach emerges when a product has been in circulation for some time already. The goal is to keep the product on the market without changing the functionality and the performance, adaptations or improvements are not desired. The adapt for AM approach allows changes of the parts production process and shape, to improve the product performance. Usually, this involves redesign processes (Diegel et al. 2019). The design for AM approach occurs during new product conceptions. Former processes, product shapes and fits, such as the product function, can be modified for this approach (Diegel et al. 2019).

Design approaches (compare Diegel et al. 2019)

Most state-of-the-art assessments are designed for adapt for AM- or design for AM approaches. The introduced method addresses direct part replacement approaches in service scenario contexts (see Fig. 3). Following this approach, respective part geometries must not be changed too drastically during redesign or adaptation processes. Functional surfaces and geometries of the part (e.g., threads or flange surfaces) have to remain the same, to ensure comparable functionality. Hence, rating aspects regarding performance improvement are not considered within this work. The addressed product development processes are driven by internal triggers on a product level (see product development triggers in Fig. 2). Therefore, the goal of the introduced method is to provide a detailed, yet comprehensive rating of an already-known product. Narrowing down or brainstorming potential products/ components is part of the scope. The internal trigger allows a certain amount of (economic) effort and time expenditure.

3.2 Assessment process

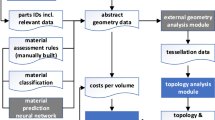

The rating process consists of several sub-assessments. Figure 4 provides an overview of the entire method. Orange elements represent inputs and outputs, navy blue elements stand for assessment processes, and dark grey elements (w1.1, w1.2 and w2) represent weights of the assessment process.

First, the prefilter examines the parts for a set of exclusion criteria, assuring basic manufacturability (see Sect. 3.2.1) and determining a score of 1 or 0. Next, the primary assessment examines restrictive and opportunistic aspects within the in-process, post-process and AM driver assessment. The prefilter result multiplied by the primary assessment output eventually results in the AM potential. Hence, if the prefilter score is rated 0 (indicating that a basic requirement is not fulfilled), the entire AM potential score results in 0, implying the component is not suited for AM. The AM adaptation potential is determined independently from the AM potential, based on the restrictive inspection outcome.

Appendix 1 contains exemplary assessment sheets. Every single component passes the entire assessment of the presented assessment sheets. To assure an easier handling of an entire assembly assessment with several components and to enable as many employees as possible to utilize, understand and adapt the assessment, the proposed method was implemented in spreadsheets. The different sections were distributed onto several sheets, to ensure clarity and user-friendliness.

3.2.1 Prefilter

The prefilter examines the component based on fundamental preconditions assuring basic manufacturability without major redesign. Parts that fulfil these preconditions can be considered for AM and continue the assessment, and parts that do not pass this filter should not be further considered for AM. It is assumed, that the optimum build direction for each part has been determined before this step. This can either be done through experienced AM users or by software tools, that suggest AM-suited part orientations to support less-experienced users. If a part performs unexpectedly badly, the part orientation might be reexamined regarding an alternative build direction.

Besides examining, if the parts fit into the build space and that suitable material is available, certain AM-sensitive geometries (e.g., overhangs) are inspected. Additionally, the assessment tool requires the user to confirm that there are no legal restrictions for building the part (e.g., patents) and that current standardization and production strategies are not significantly more cost-efficient than AM.

Certain geometric aspects (e.g., bridges) are examined again in the restrictive in-process assessment, since fulfilling the fundamental preconditions only assures basic manufacturability, but does not assure high manufacturing quality (compare scoring thresholds in Tables A1.1 and A1.2 of appendix 1 for further details). The examined aspects are a collection of aspects from Booth et al. (2017), Bracken et al. (2020) and Ley et al. (2017). Table 4 presents a first overview of considered aspects and sources, further assessment details are provided in table A1.1 of appendix 1. Each aspect is rated 1 (acceptable) or 0 (not acceptable), before multiplying all scores. As a result, whenever one of the aspects is rated 0, the total prefilter score will become 0 immediately, and with that the entire AM potential score (see Fig. 4). This calculation method and the general concept of implementing a prefilter for exclusion criteria are adopted from Knofius et al. 2016.

3.2.2 Primary assessment

While the prefilter process solely ensured certain minimum or maximum levels (binary rating), the primary assessment results in an assessment range from 0 (worst) to 4 (best). This range differentiates from the 1 or 0 to 5 scale of state-of-art works and is selected based on the VDI guideline VDI 2225–3, (1998) to comply with current industry standards. A standardized value range enables users to compare the assessment results with other standardized part analyses (e.g., assessments of alternative conventional production processes). Additionally, a range from 0 to 4 allows users to choose a score of 2 as the median, which does not exist for a range from 0 to 5. As the aspects within the three assessment blocks are considered equally important, mean values are determined for interim statements.

The primary assessment consists of a restrictive and an opportunistic inspection (see Fig. 4). The restrictive inspection consists of an in-process and a post-process assessment, the opportunistic inspection solely assesses the AM drivers. The outcomes of these three assessments are individually weighted (w1.1, w1.2 and w2 in Fig. 4), to enable scenario-based adaptation of the primary assessment towards different product development triggers and design approaches. The in-process assessment focuses on geometric features (e.g., holes, pockets, overhangs etc.). The post-process assessment evaluates necessary post-processing procedures, to meet part-specific requirements (e.g., for functionality or aesthetics). The assessed aspects of the restrictive inspection are largely adopted from those examined in Booth et al. (2017), Bracken et al. (2020) and Ley et al. (2017). Table 5 provides a first overview of assessed in-process aspects and respective sources, Table 6, respectively, for the post-process assessment. Further assessment details are provided in table A1.2 and table A1.3 of appendix 1. The scoring thresholds for each score (0 to 4) were chosen based on literature review (compare sources in Tables 5 and 6) and expert knowledge and should be adjusted based on the respective situation (e.g., machine performance, material characteristics), which can be done by test printing reference parts.

The complexity is measured with a complexity parameter, based on two approaches. One is the “Spies Ratio” (proposed in Spies 1959), which is defined as follows:

The other is an approach proposed by Valentan et al. (2011), described as

A combination of these two approaches finally results in the Complexity Parameter (CP) used within this paper

The scoring thresholds of the complexity assessment were distributed relatively to the CP values of the present assembly and should be adjusted based on individual complexity levels of assessed components.

The AM drivers are repercussions of AM, affecting the product or production process, leading to various AM value propositions for manufacturers, customers or societies in general (see Fig. 5). This includes economic aspects, eco-social impacts and improvements in product functionality or production processes. This AM driver concept is based on the “enablers” and “objectives” proposed in Schneck et al. (2019). Assessed AM drivers and their respective sources are displayed in Table 7. Further assessment details are provided in table A1.4 of appendix 1. As the relevance of these aspects might differ dependent on boundary conditions (see Sect. 3.1), AM drivers are individually weighted instead of just determining the mean value.

Figure 5 illustrates the identification of the AM driver weights, which depend on several aspects. As previously mentioned, every AM driver leads to one or more value propositions. Further, these AM value propositions might be regarded with diverging priorities and preferences by the stakeholders involved. The proposed weight determination is based on the fundamentals of utility analysis. Once stakeholder priorities have been rated, AM value propositions are prioritized from stakeholders’ perspectives. The AM value proposition weights are determined utilizing these values. Next, the AM drivers are assigned to value propositions they lead to (multiple links in both directions possible). Eventually, the AM driver weights can be determined based on the assignments and the weights of the corresponding AM value propositions.

3.2.3 AM adaptation potential

A high AM adaptation potential highlights parts that might benefit from marginal changes in non-functional geometries regarding additive manufacturability. It suggests and approximates the efficiency of conceivable changes, which might have a positive impact on the AM potential (compare Kim et al. 2019, Ghiasian and Lewis 2022 and the outlook of Bracken et al. 2020 and Bracken Brennan et al. 2021). This score is automatically calculated based on the prior restrictive inspection, as the AM adaptation potential properties are linked to corresponding aspects of the restrictive inspection (see primary assessment in Sect. 3.2.2).

For example, if the support structure removability obtained the lowest possible score (rating equal to 0), because the components’ support structures are very hard or impossible to remove, the corresponding AM adaptation potential aspect reduce support structure will obtain the highest possible score (rating equal to 5), indicating a high potential for improvement in this respect. Table 8 shows the evaluated aspects of the AM adaptation potential assessment, further details can be found in table A1.5 of appendix 1. These aspects are mainly geometric properties which can be easily adopted (e.g., changing a round hole to a diamond- or teardrop-shaped hole).

3.3 Usage and evaluation instructions

The instructions given in the following are solely recommendations based on the original idea of the method. Any productivity-enhancing adjustments can certainly be made individually throughout the process. Before any product/component-specific rating can take place, the framework must be set. This includes strategic information (namely assessing stakeholder priority and value propositions or matching AM drivers and AM value propositions) and process-related information (e.g., build space, correction factors etc.). This initially set data can be reused company-wide, provided that the same machines and strategic conditions apply.

For efficiency reasons, merely parts which passed the prefilter should be rated in the ensuing primary assessment process. Hence, the first data input package for all considered parts should be the required information for the prefilter process. Next, the in-process and post-process assessment of the qualified parts can take place. Once this step has been finished, the AM adaptation potential should be examined. The AM adaptation potential is determined as fully automated, so reviewing this score does not require any further data inputs. Identifying parts with a high AM adaptation potential, and if necessary, briefly improving their geometry towards AM suitability, might be profitable before moving on to the final opportunistic assessment.

A final evaluation of achieved scores should always be done holistically. An intermediate total AM potential score might originate from intermediate performances in both interim inspections. The interim inspection performances could just as likely have large discrepancies (see Sect. 4). Figure 6 illustrates an overview of recommended actions, based on obtained scores. An overall AM potential score beneath 40% implies low AM suitability. This AM potential occurs when at least two out of ten in-process assessment aspects, one out of four post-process assessment aspects, and one out of seven opportunistic assessment aspects are rated with the lowest score (rating equal to 0), and the remaining aspects receive an intermediate score (rating equal to 2). If the part scores 40%-65%, a careful examination of obtained interim results is recommended (e.g., to identify conspicuities for either of the aspects). Scores within this range imply that AM might be considered. AM potential scores above 65% indicate a general AM suitability for the respective part. This AM score results, when at least three out of ten in-process assessment aspects, one out of four post-process assessment aspects and two out of seven opportunistic assessment aspects are rated with the highest possible score (rating equal to 4) and the remaining aspects receive an intermediate score (rating equal to 2).

An AM adaptation potential of 6 or higher indicates a high potential for improvement, since at least one geometric property scored 5 points. The origin of this potential should be verified, and the chances of AM adaptation should be reviewed. An AM adaptation potential of 3 or lower implies a low AM adaptation potential, as the respective part shows no more than three aspects, that could be adapted, each of those with a low improvement potential.

4 Application, results, and discussion

The introduced assessment method was exemplarily applicated to the components of a gas turbine pilot nozzle assembly.

4.1 Initial preparations

In preparation for the component assessment, the strategic assessments were conducted. This assessment was carried out by the author in cooperation with two industry experts from the producing company. Eventually, the average values were determined. The stakeholder relevance was rated while assuming that the producing company has a customer-centred philosophy. The AM value propositions were ranked by performing pairwise comparisons (compare Bender and Gericke 2021 p. 315 f.) for every stakeholder. The final AM value proposition priorities are presented in Fig. 7. The consequential AM driver weights are displayed in Fig. 8. Due to a lack of information on production processes, the production-time weight of the opportunistic inspection was manually set to 0% (see Fig. 8).

4.2 Assessment of assembly and components

Figure 9 presents the assessed assembly and its components. Table 9 describes the observed components and provides further information about the geometry.

4.3 Results

The proposed method was applied to the introduced assembly. Detailed assessment results of the entire assembly can be found in appendix 2. It becomes apparent that almost half of the components (5 out of 11) did not pass the prefilter, and the reasons were high standardization levels and low production complexity. Most parts can be externally acquired for an equitable price (components A, D, J and K) or be manufactured conventionally with considerably low effort (component C). The remaining parts successfully passed the prefilter (rating equal to 1). Figure 10 further visualizes the assessment outcome, including three different weight-distribution scenarios. Table 10 provides an overview of set weight distributions for each scenario.

Dependent on set priorities, components E, F, G and I obtained differing recommendations for action. These varying weight distributions point out how relevant the strategic mindset is for production decisions. Component H obtained the highest AM adaptation potential of 7, pointing out that the geometry currently requires an exceptionally high amount of support structure. Part B obtained a relatively high AM adaptation potential of 5 due to conspicuously low wall thicknesses. In further process, both parts were considered for subsequent redesign approaches. Furthermore, part B had already obtained a relatively high AM potential in advance. The AM adaptation potential therefore pointed out a potential geometric blind spot, that might not have been determined without a subsequent AM adaptation potential examination. Section 4.6 further examines this matter.

The overall results were discussed with AM experts with satisfactory knowledge about the assessed components, related requirements such as present production details. The assessment outcome was rated comprehensible, as it met their expectations based on former (qualitative and less conceptual) evaluations.

The procurement of required information for the primary assessment turned out rather time-consuming, as it was done manually in this case. Especially, gathering the geometric properties of more complex parts turned into a laborious process. However, in an industrial context, the majority of examined properties can be imported from CAD systems, PLM and/ or ERP systems.

This method and its implementation in spreadsheets allow users to fully understand the assessment outcome, since interim results are accessible throughout the entire process. In contradiction to machine learning approaches, which often lack transparency, the proposed method allows complete plausibility checks and troubleshooting. Despite taking a plethora of information into account, the method is still easy to understand and uncomplicated to use. In contrast to Kruse et al. (2017), critical calculations and weight determinations are performed automatically and do not require an expert to be set. Therefore, any company employee who has acquired sufficient knowledge (see Sect. 3.1 for details) can execute the assessment autonomously.

4.4 Extreme cases and sensitivity towards primary assessment weights

Component B obtained a comparably high AM potential and showed an insensitive response towards varying weight distributions. On the other hand, components E and G showed comparatively high sensitivity towards varying weight distributions, making a final statement highly dependent on previously set weights (see Fig. 10 and Table 11). The robustness of part B towards varying assessment weights was mainly caused by high-level scores in both restrictive and opportunistic inspections. In contrast, the relatively high discrepancy between restrictive and opportunistic inspection outcomes of parts G and E resulted in a high sensitivity towards varying weight distributions.

This finding emphasizes the importance of independently inspecting both aspects. A momentary low AM potential should not strictly entail a decision against AM. A further inspection of restrictive and opportunistic aspects is highly recommended, since individual outcomes provide a significantly clearer statement about the current situation and incorporated potentials. In case the inspection of the primary assessment reveals similar scores for both inspections (components located near the yellow line in Fig. 11), the parts’ assessment results will remain insensitive towards varying weight distributions.

If parts score very low in the opportunistic inspection and very high in the restrictive inspection (i.e., would be additively manufacturable but utilizing AM does not involve significant benefit) the opportunistic inspection and with that the previously set driver weights should be analyzed and challenged. If, for example, a business case reveals a highly economic-added value, the part might be considered nevertheless. If a part scores high in the opportunistic inspection and very low in the restrictive inspection (i.e., turns out to bear very high potential benefits but currently cannot be manufactured additively), users should have a close look at the AM adaptation potential. In case of an intermediate or high AM adaptation potential, a redesign process is highly recommended to reach AM suitability. Summarizing, if one of the aforementioned cases arises, respective components should not be discarded, but placed in the backlog and treated accordingly once company capacities allow it (see grey ellipses in Fig. 11).

4.5 Sensitivity towards AM driver weights

Similar to the primary assessment weights, the sensitivity of a component’s assessment outcome towards the driver weights depends on individually achieved driver scores. If the driver assessment results in similar scores over all drivers, the sensitivity will be comparably low; if a component achieves diverging driver assessment results, the AM potential score will be highly sensitive towards varying driver weights. For certain components, it might even result in completely different recommendations for action, depending on the weight distribution. Figure 12 shows the outcome of an exemplary variation of AM driver weight distributions (the corresponding distribution of driver weights can be found in Appendix 3 in detail). A high scattering implies a high sensitivity towards varying weight distributions. In consideration of the assessment outcomes in Table 12, it becomes apparent that components F and G appear less sensitive towards varying AM driver weights than the remaining parts, because the AM driver assessments showed fewer discrepancies.

4.6 Effect of the AM adaptation potential on the final results

Considering the AM adaptation potential score of 5, component B might achieve an even higher AM potential than it already did, after applying slight geometrical adjustments. This finding additionally underlines the components’ AM suitability. Due to a comparatively low restrictive assessment score, component H permanently remained in the transition range. Nevertheless, a conspicuously high AM adaptation potential indicates that minor geometrical alterations might cause a significant rise in the AM potential level, which could result in AM suitability for component H.

5 Conclusion and outlook

The proposed assessment method supports users with basic AM knowledge in identifying and rating AM suitability of parts. It is especially suited for companies who want to incorporate AM into existing product portfolios and improve existing processes but lack knowledge of AM within the company. The method assists in making justified and less-biased decisions, based on a comprehensive and reproducible examination. In this way, employees have the opportunity to slowly become familiar with the technology while learning on the job.

The implementation in spreadsheets entails a solid level of semi-automatization, while still retaining traceability. The choice of a value range from 0 to 4 (see Sect. 3.2.2) bares the potential of contributing towards a standardized AM potential assessment and making it comparable to assessments of other production methods. This could enable users to determine quantified assessments of several types of production methods. The assessment results would allow users to compare the production processes and choose the best solutions for present use cases. A brief introduction and presentation of the method to AM experts resulted in positive general feedback. Nevertheless, the methods’ practicability and precision of given statements such as set assessment thresholds should be constantly challenged and adjusted towards evolving standards if necessary (e.g., due to evolving technology standards).

Most state-of-the-art works introduce methods, that focus on either restrictive or opportunistic assessments, failing to include both categories (e.g. Booth et al. 2017, Bracken et al. 2020, Ley et al. 2017, Kim et al. 2019, Lindemann et al. 2015; Kruse et al. 2017). Research that considers both aspects evaluates a comparably small number of properties. The proposed method ensures the consideration of a maximum amount of relevant aspects for both perspectives. Users possess a statement about the overall AM potential (AM potential score) and can likewise obtain differentiating statements about manufacturability (restrictive inspection score) and estimated beneficial effects (opportunistic inspection score). Additionally, the proposed approach considers socio-ecological aspects. Dependent on individually rated value propositions and stakeholder priorities, this aspect might have a significant impact on the overall assessment (see Sect. 4.5). Compared to Lindemann et al. 2015 and Kruse et al. 2017, considerable progress has been made regarding the opportunistic assessment, by incorporating value propositions and stakeholder interests while determining AM driver weights. Moreover, potentially AM-critical geometries or aspects are highlighted, ensuring a plausible documentation and traceable rating process, maintaining the advantages of Booth et al. (2017) and Bracken et al. (2020). Besides a statement on AM suitability, users additionally receive feedback on potential geometrical adaptations that might induce an even higher AM potential score, including an estimation of effectiveness. This feedback bares a close resemblance to the approach introduced by Kim et al. (2019) and Ghiasian and Lewis (2022). However, Kim et al. (2019) solely give redesign recommendations, while the AM adaptation score additionally indicates the effectiveness of the respective adaptation. Ghiasian and Lewis (2022) provide automatically redesigned models and their originals as an output. Consequently, the AM adaptation potential of selected optimizations is not assessed either and AM optimizations appear intransparent for users.

The assessment process of this paper is designed for a clearly defined framework (see Sect. 3.1 and Fig. 13). A modification of the assessment process towards other triggers, design approaches, or alternative AM production methods are conceivable enhancements. Adapt for AM- or design for AM approaches require adapted evaluation aspects. Performance improvement, for instance, plays a general role in these approaches. The AM drivers should be completed or modified regarding aspects like conformal cooling, energy consumption, parts consolidation, lifetime or repairability. Assessing externally triggered design processes (see Fig. 13) requires individually set thresholds, based on competitors or new regulations. Processes triggered on a strategic level require prefiltering with an additional, less precise, evaluation system in advance or carrying out (brainstorming) workshops to narrow down potential components from the entire product portfolio.

The part orientation in the build space has a significant impact on assessment results. Thus, it would be useful to execute an algorithm in advance, which considers different options to find the best possible orientation, addressing several aspects (e.g. build space, minimum support structures, etc.) simultaneously.

Finally, an ongoing objective should be automatizing and improving the entire assessment process as much as possible, while nevertheless maintaining the transparency of the assessment at all times. Currently manually assessed properties could be inspected regarding automatically measurable parameters, to expand the degree of automation. For instance, the restrictive inspection and the AM adaptation potential evaluation could be automated, as a majority of necessary data for these inspections can be collected from CAD and ERP systems. With an automatization of these processes, the prefilter process would become unnecessary, since the prefilter was installed for efficiency reasons during a manual assessment. In summary, the entire assessment process could become a two-stage process consisting of an automatized restrictive assessment with a statement about restrictive AM potential and consequent AM adaptation potential, followed by a manual opportunistic assessment of manufacturable parts.

Data availability

The CAD data owner of the assembly assessed in this study did not give written consent for their data to be shared publicly. The spreadsheet templates for part selection and data that support the findings of this study are available from the corresponding author, DG, upon reasonable request.

References

Ahtiluoto M, Ellman AU, Coatanea E (2019) Model for Evaluating Additive Manufacturing Feasibility in End-Use Production. Proc. Int. Conf. Eng. Des.:799–808. https://doi.org/10.1017/dsi.2019.84

Bender B, Gericke K (2021) Pahl/Beitz Konstruktionslehre. Springer, Berlin Heidelberg, Berlin, Heidelberg

Bin Maidin S, Campbell I, Pei E (2012) Development of a design feature database to support design for additive manufacturing. Assembly Automation 32. https://doi.org/10.1108/01445151211244375

Booth JW, Alperovich J, Chawla P, Ma J, Reid TN, Ramani K (2017) The Design for Additive Manufacturing Worksheet. Journal of Mechanical Design Doi 10(1115/1):4037251

Bracken J, Pomorski T, Armstrong C, Prabhu R, Simpson TW, Jablokow K, Cleary W, Meisel NA (2020) Design for metal powder bed fusion: The geometry for additive part selection (GAPS) worksheet. Addit Manuf. https://doi.org/10.1016/j.addma.2020.101163

Bracken Brennan J, Simpson TW, McComb C, Jablokow KW, Hamann J (2021) Part filtering methods for additive manufacturing: A detailed review and a novel process-agnostic method. Additive Manufacturing 47:102115. https://doi.org/10.1016/j.addma.2021.102115

Diegel O, Nordin A, Motte D (2019) A Practical Guide to Design for Additive Manufacturing. Springer Singapore, Singapore

DIN EN ISO/ASTM 52911–1 (2020) Additive manufacturing - Design - Part 1: Laser-based powder bed fusion of metals. DIN Deutsches Institut für Normung e. V.

Ghiasian SE, Lewis K (2022) A Recommender System for the Additive Manufacturing of Component Inventories Using Machine Learning. Journal of Computing and Information Science in Engineering. Advance online publication. https://doi.org/10.1115/1.4051342

Ghiasian SE, Jaiswal P, Rai R, Lewis K (2018) From Conventional to Additive Manufacturing: Determining Component Fabrication Feasibility. In: Volume 2A: 44th Design Automation Conference. American Society of Mechanical Engineers

Kim S, Rosen DW, Witherell P, Ko H (2019) A Design for Additive Manufacturing Ontology to Support Manufacturability Analysis. Journal of Computing and Information Science in Engineering:1107. https://doi.org/10.1115/1.4043531

Knofius N, van der Heijden MC, Zijm W (2016) Selecting parts for additive manufacturing in service logistics. Journal of Manufacturing Technology Management:915–931. https://doi.org/10.1108/JMTM-02-2016-0025

Kruse A, Reiher T, Koch R (2017) Integrating AM into existing companies - selection of existing parts for increase of acceptance

Kumke M, Watschke H, Vietor T (2016) A new methodological framework for design for additive manufacturing. Virtual and Physical Prototyping 11:3–19. https://doi.org/10.1080/17452759.2016.1139377

Kumke M, Watschke H, Hartogh P, Bavendiek A-K, Vietor T (2017) Methods and tools for identifying and leveraging additive manufacturing design potentials. Int J Interact Des Manuf 12:481–493. https://doi.org/10.1007/s12008-017-0399-7

Laverne F, Segonds F, Anwer N, Le Coq M (2015) Assembly Based Methods to Support Product Innovation in Design for Additive Manufacturing: An Exploratory Case Study. Journal of Mechanical Design 137. https://doi.org/10.1115/1.4031589

Leutenecker-Twelsiek B (2019) Additive Fertigung in der industriellen Serienproduktion: Bauteilidentifikation und Gestaltung, ETH Zurich

Ley M, Hilbert K, Buschhorn N, Stephan N (2017) Obsoleszenzmanagement unterstützt durch additive Fertigung: Von der Bauteilidentifikation bis zum fertigen Ersatzteil. Stuttgarter Symposium für Produktentwicklung 2017

Lindemann C, Jahnke U, Reiher T, Koch R (2015) Towards a sustainable and economic selection of part candidates for Additive Manufacturing. Rapid Prototyping Journal

Lu T (2016) Towards a fully automated 3D printability checker:922–927. https://doi.org/10.1109/ICIT.2016.7474875

Mayerhofer M, Lepuschitz W, Hoebert T, Merdan M, Schwentenwein M, Strasser TI (2021) Knowledge-Driven Manufacturability Analysis for Additive Manufacturing. IEEE Open J Ind Electron Soc 2:207–223. https://doi.org/10.1109/OJIES.2021.3061610

Molina VR, Reyes Rey L, Werner S, Göhlich D (2022) Method for Function-Based Identification of Potential AM Components in Conventional Product Architectures. Proc Des Soc 2:505–514. https://doi.org/10.1017/pds.2022.52

Page TD, Yang S, Zhao YF (2019) Automated Candidate Detection for Additive Manufacturing: A Framework Proposal. Proc. Int. Conf. Eng. Des.:679–688. https://doi.org/10.1017/dsi.2019.72

Schneck M, Gollnau M, Lutter-Günther M, Haller B, Schlick G, Lakomiec M, Reinhart G (2019) Evaluating the Use of Additive Manufacturing in Industry Applications. Procedia CIRP 81:19–23. https://doi.org/10.1016/j.procir.2019.03.004

Spies K (1959) Die Zwischenformen beim Gesenkschmieden und ihre Herstellung durch Formwalzen. Forschungsberichte des Landes Nordrhein-Westfalen, vol 728. VS Verlag für Sozialwissenschaften, Wiesbaden, s.l.

Valentan B, Brajlih T, Drstvenšek I, Balič J (2011) Development of a Part-Complexity Evaluation Model for Application in Additive Fabrication Technologies. Strojniški vestnik - Journal of Mechanical Engineering

VDI 2225–3 (1998) Design engineering methodics - Engineering design at optimum cost - Valuation of costs. VDI Verein Deutscher Ingenieure

Winkler M, Jacobs G, Sturmer S, Konrad C (2020) Application of data mining for the identification of parts for additive manufacturing:281–288. https://doi.org/10.1109/ICIEM48762.2020.9160307

Yang S, Page T, Zhang Y, Zhao YF (2020) Towards an automated decision support system for the identification of additive manufacturing part candidates. J Intell Manuf:1917–1933. https://doi.org/10.1007/s10845-020-01545-6

Acknowledgements

The authors would like to thank Simon Purschke and Johannes Albert (Siemens Energy) for their support, and feedback on the method with respect to applicability.

Funding

Open Access funding enabled and organized by Projekt DEAL. The project “WvSC–HTA 2.0: HochTemperaturAnwendungen 2.0” is funded by the European Regional Development Fund (10167551). This work was carried out within the framework of the Werner-von-Siemens Centre for Industry and Science (https://wvsc.berlin/).

Author information

Authors and Affiliations

Contributions

NS: investigation, methodology, and writing—original draft, visualization; VM and SW: conceptualization, supervision, validation, writing—review and editing, and project administration; DG: resources, writing—review and editing, project administration, and funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: exemplary assessment sheets

See Tables 13, 14, 15, 16, 17.

Appendix 2: assessment results

Brief part description

See Tables 18, 19, 20, 21, 22.

Appendix 3: AM driver weight distributions for sensitivity analysis

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Siller, N., Werner, S., Molina, V. et al. Method for potential assessment and adaptation for additive manufacturing of conventionally manufactured components. Res Eng Design 35, 73–96 (2024). https://doi.org/10.1007/s00163-023-00421-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00163-023-00421-7