Abstract

The design of circular products is gaining relevance among academics, practitioners, and industry as a critical step to face material scarcity, the unsustainability of industrial processes, and excessive waste generation. Therefore, product design is a powerful research field to promote material, component, and product circularity throughout several lifecycles. However, there is a lack of formal methods to measure the circularity of products, especially from the early design stages. Therefore, this paper proposes a diagnostic tool for measuring circularity, identifying potential improvement opportunities, and redesigning interventions in the conceptual design phase. The tool consists of eight single indicators that measure disassemblability, reassemblability, durability, modularity, simplicity, standardization, commonality, relative costs, and the number of secondary functions of products. A case study is presented to validate the tool, considering several improvement scenarios around the 6R strategies. Finally, a list of redesign interventions for each improvement scenario was assembled as a primary output of the proposed tool.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Circular Economy (CE) is a trending topic that aims to minimize resource use and emissions by slowing, closing, and narrowing products, parts, materials, and energy flow loops (Bocken et al. 2016). In recent years, research efforts have concentrated on overall lifecycle interventions that include selecting low-impact materials, reducing material use, optimizing production techniques or technologies, distribution systems, and lifetime (Mestre and Cooper 2017). Circularity strategies can be divided into two main groups. The first one includes strategies for recirculating parts and products, such as upgrade, repair and maintenance, reuse, refurbishing, remanufacturing, and repurposing. The second group, dedicated to material recirculation, involves recycling, cascade, and recovery (Blomsma et al. 2019).

The design phase system considers all possible strategies to increase the circularity of products, components, and materials (Ellen MacArthur Foundation 2015). Nevertheless, design approaches and guidelines to identify or determine which product attributes or characteristics need to be modified to increase circularity are still under development (Bocken et al. 2016), especially when implementing more than one strategy. On the other hand, most research efforts focus on material recirculation strategies, especially around recycling, which is commonly included in methodological approaches, design guidelines, and indicators for measuring product circularity (Allwood 2014). Therefore, there is a need for more research to cover product and component circularity to enhance product lifespans. There is limited literature on detailed design interventions to improve circularity for products and components. Instead, the vast majority of approaches are based on measuring circularity potential for material recycling like the Material Circularity Indicator—MCI (Ellen MacArthur Foundation—EMAF 2015), the Circular Economy Index—CEI (di Maio and Rem 2015), or the Recycling Rates—RR (Haupt et al. 2016)), while other approaches are focused on specific CE strategies (i.e., reuse, refurbish, remanufacture, and repair) like Reuse Potential Indicator—RPI (Park and Chertow 2014), or the Resource Duration Indicator—RDI (Franklin-Johnson et al. 2016). As a common denominator of previous research, there is no formal approach to identifying product attributes that need to be addressed during the design phase to enhance their performance in products and components.

This paper proposes a diagnostic tool to measure product circularity and identify potential improvement interventions for redesign scenarios. This proposed tool is meant to help designers, manufacturers, and practitioners identify product attributes and features that affect product circularity and to encourage the generation of more circular redesign alternatives during the conceptual design stage. The proposed tool includes eight product attributes that provide a quantitative analysis of circularity performance in terms of upgrade, repair and maintenance, reuse, refurbish, remanufacture, and repurposing. A case study revealed single and combined interventions that positively impact the circularity performance of the product.

The remainder of this paper is organized as follows. Section 2 presents the research background around the design of circular products, attributes, and circularity metrics. Section 3 describes the proposed tool, with emphasis on the methodological steps. Section 4 evaluates the proposed tool through a case study, while results are discussed in Sect. 5. Finally, in Sect. 6, conclusions are presented.

2 Background

2.1 Circular economy strategies

CE emphasizes the design—or, perhaps, more accurately—the redesign of products and services to facilitate restorative mechanisms (Tam et al. 2019). Figure 1 shows the classification of nine CE strategies based on recirculation of parts and products and the recirculation of materials. Commonly, a better circularity performance is often achieved through the top eight strategies, since the last three imply additional energy and resource consumption. For example, recycling and cascade typically require energy and water for cleaning, handling, and homogenizing materials. Here, virgin material helps to ensure an acceptable quality of the resulting raw material. In addition, the inefficiencies of all equipment and handling systems need to be considered.

Degree of circularity for 9R's strategies. Comparison of desirability and consumption of resources. Based on Blomsma et al. (2019)

In the case of recovery, thermal energy generation from materials is the less-preferable strategy, especially for non-biological materials, because of the potentially harmful emissions. Nevertheless, in some cases, recycling, cascade, and recovering are more suitable due to risk elimination (e.g., medical disposable products). However, as mentioned earlier, all those strategies involve a certain degree of circularity. In the case of product design, strategies related to the recirculation of parts and products can be employed to extend the existing lifecycle of products or to promote their incorporation into new ones. Each one of these strategies is described below.

According to Pialot and Millet (2014), upgrading is a functional enrichment process that applies when a product reaches one of two conditions: (i) physical lifetime, which involves a product failure, and (ii) value lifetime, which occurs when the product is disposed of because its performance, functionality, or appearance cannot satisfy the customer needs anymore. Upgradeability is commonly associated with remanufacturing, which implies the reconditioning of existing products to satisfy a new use cycle. Upgradeability is one of the key criteria for design based on lifecycle aimed at service life extension. A modular structure of products is required to facilitate the transition between different product generations by adding or replacing the modules for the next generation of the product life cycle (Aziz et al. 2016).

Repair and maintenance imply keeping a product usable and in a good state, as long as possible to prolong its lifetime (Ackermann 2018). Therefore, this is a key strategy toward more sustainable consumption based on a circular economy (Aguiar et al. 2022), Hebrok 2014), Mestre and Cooper 2017). Research has been oriented toward facilitating repair and maintenance tasks (van Nes and Cramer 2005), Vezzoli and Manzini 2008). Some of the most relevant design approaches include Design for Disassembly. Furthermore, repair and maintenance are recently gaining relevance in product-service systems (Baines et al. 2007), which implies alternative ways of product use, like renting or sharing instead of purchasing. Reuse is one of the most studied strategies and entails extending the product’s lifetime to the maximum possible. This strategy implies environmental, social, and economic benefits when considered from the early design phases (Zacho et al. 2018), since it avoids manufacturing new products and prolongs the product's use time, even in multiple lifecycles among different users in distinct generations. It facilitates purchasing second-hand products and value recovery for the initial consumer. Additionally, reuse provides higher advantages than other CE processes that imply additional transformation processes (i.e., recycling) and, therefore, a higher implicit environmental desirability (Zink et al. 2014).

Refurbishment is another strategy covered by the circular economy concept, considered the most profitable and environmentally beneficial process, demonstrated by a growing trend of manufacturers with product collection and refurbishment programs (Chen et al. 2018). Refurbishment is defined as “return a used product to a satisfactory working condition by rebuilding or repairing major components that are close to failure, even where there are no reported or apparent faults in those components” [British Standard BS8887-2–2009 Design for Manufacture, Assembly, Disassembly and End-of-Life Processing (MADE), 2009]. Recently, this strategy is also related to circular business models based on leasing, where refurbishment is considered a value recovery strategy (Sumter et al. 2018).

Another crucial strategy is Remanufacturing, which has experienced a gradual rise with solid interest from researchers and government bodies alike to face resource scarcity in the field of product manufacturing (Cao et al. 2021). Remanufacturing consists of restoring used products to a like-new or better state, offering the same warranty as a new product (Burggräf et al. 2021). Remanufacturing includes several industrial processes, such as collection, dismantling, repair, and testing (Krystofik et al. 2018). The most relevant savings of remanufacturing lie in energy consumption (60%), metallic materials (70%), and emission of air pollutants (Kelly et al. 2017). Finally, Repurposing is one of the less-known circular economy strategies. This strategy is defined as the reuse of a product for other applications, not necessarily equal to those that the product had in origin (Cooper and Gutowski 2017). Repurposed products have an environmental advantage compared to market products. In the case of electronic and electric products, it is possible to reach an environmental impact of between 25 and 80% less than in a scenario without repurposing (Pérez-Martínez et al. 2021).

2.2 Attributes of circular products

This subsection expands on the identification and characterization of circular products to define which product attributes need to be considered for each CE strategy. From such attributes, it is possible to identify the interventions regarding materials, geometry, and joints during the early design stages for the six strategies related to the recirculation of parts and products. A literature review in SCOPUS enabled the identification of the main attributes of circular products considered in previous research. The detailed search queries are summarized in Table 1, including the total number of articles identified and selected for this study. Table 2 summarizes eight attributes associated with CE strategies for recirculating parts and products proposed by Blomsma et al. (2019) and identified in the literature.

2.3 Design tools for circular products

A growing trend of product development methodologies related to sustainability resulted in different “Design-for-X” approaches during the last 2 decades. Those approaches consist of design methods, guidelines, and rules to incorporate an “X” attribute, such as environment, durability, and recyclability, among others, during the product development process. At this point, it is possible to identify noteworthy relationships between Design-for-X approaches and CE strategies. Table 3 summarizes 36 Design-for-X approaches and their associations with CE strategies.

After reviewing the most relevant product attributes regarding CE in product design research, it is possible to relate them to the six CE strategies. Figure 2 shows the relationships and matches between CE strategies to extend product lifespan and required attributes according to existing literature. The analysis showed that Disassemblability, Reassemblability, Durability, and Modularity are transversal attributes required to support all strategies related to the recirculation of parts and products. Standardization plays a key role as well, involved in five out of six strategies. Finally, other attributes like simplicity, commonality, and affordability of spare parts play a relevant role, but only in four strategies. Another product attribute is the possibility of secondary functions, thus enabling product repurposability.

2.4 Metrics for product circularity

In terms of indicators or metrics related to the circularity of products or parts, just a few approaches cover the analysis of attributes involved in the design process. Most indicators or metrics associated with circularity and found in the literature, like RR (Haupt et al. 2016), MCI (Ellen MacArthur Foundation—EMAF, 2015), and CEI (di Maio and Rem 2015), are focused on recycling, while other approaches are concentrated only in a unique CE strategy, like RPI (Park and Chertow 2014) or RDI (Franklin-Johnson et al. 2016). However, it is possible to find more comprehensive approaches to measuring overall circularity (including all CE strategies). This literature review identified five indicators oriented to the product level and identified current research gaps. Table 4 summarizes such approaches and includes an overall description and calculation parameters for each indicator or metric.

After analyzing the existing circularity indicators, a lack of coverage of CE strategies for recirculating parts and products is noticeable. The following research gaps were identified:

-

Approaches listed in Table 4 are mainly based on questionnaires and relative weights, which implies a degree of subjectivity in the decision-making process related to improvement actions.

-

Some indicators are based on the product's overall performance as a black box, skipping the detailed circularity from components. Therefore, the design interventions can be limited to general geometry and material selection.

-

Existing approaches do not consider the impact on all CE strategies when improving a single strategy. Thus, enhancing durability benefits remanufacture and upgrade, but the strategic plan can be oriented to a single strategy.

-

None of the indicators provides guidelines on design tasks or interventions to improve product circularity with detailed, measurable parameters.

3 Developing a diagnostic tool for product circularity

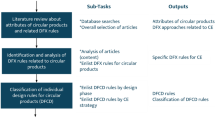

This section describes the four main steps that comprise the proposed approach. The first step provides valuable diagnostic data on the current circularity performance of the product. Later, the second one includes the definition of target values oriented to improve product performance in circularity. Then, the third step consists of analyzing CE attributes and selecting those that represent major interests or improvement opportunities for the design team or company. Finally, the last step is dedicated to generating specific design modifications that must be implemented during the product redesign to reach the previously defined circularity goals. Figure 3 shows the sequence and outputs of each step proposed in this approach.

3.1 Circularity diagnostic

This first stage aims to obtain data from the product, its circularity performance, and even gaps compared to competitors’ products. Thus, two main tasks encompass the circularity diagnostic: product inventory, which summarizes all parts that comprise the product, and the calculation of product attributes related to the CE strategies. Product inventory demands disassembling the whole product and quantifying the number of parts and pieces that comprise the product. The inventory can be arranged using a table. Then, product attributes are calculated to measure the product's circularity. Such calculation is performed using eight parameters: Dis/Reassemblability, Durability, Modularity, Simplicity, Standardization, Commonality, Relative cost of spare parts, and Secondary Functions. Table 5 summarizes the attributes and their corresponding equation and description. The same attributes should be calculated when competitors are present in the market to consider improvement goals based on competitiveness. Appendix A summarizes the definition of parameters for C1, C2, and C8.

3.2 Definition of target values

Once the circularity diagnostic is done, it is time to select which CE strategy will be improved, considering that any circularity intervention can positively impact others. Definition of target values must be developed considering the following aspects:

-

a.

Interests of the company based on its product development planning in the mid term and long term, in addition to the previously settled corporate sustainability goals.

-

b.

The differential added value offered by the company or competitors. Thus, the company does not necessarily require to surpass competitors’ performance in product circularity if there are other attributes highly desired by the customer. The improvement could be solely oriented to reducing the circularity gap existing between the company and competitors.

-

c.

Availability of resources to develop redesign process iterations, including highly qualified personnel, manufacturing technologies, and prototyping testing resources.

-

d.

Customer consciousness on product circularity and market acceptance regarding more circular products.

The definition of target values is, therefore, a particular task that depends on the company's capabilities and goals, market competitiveness, and cultural context. There is a specific set of target values depending on the decision-making scenario.

3.3 Circularity improvement

One or more modifications can be proposed to improve the strategy's performance. In this step, the attributes involved in each CE strategy need to be revised and analyzed to select those that can be modified to increase the desired circularity performance. The modifications should be presented as improvement scenarios oriented to a specific CE strategy. The number of improvement scenarios also depends on the company’s interest in analyzing several circular approaches. This step also involves recalculating attributes employed during the circularity diagnostic and comparing such values as related to the initial values. This process can be iterative until reaching the desired value for the strategy of interest.

3.4 Generation of potential redesign modifications

This last step includes the potential design interventions that can be performed to reach the target values previously established. Following the conventional structure of design requirements, these specifications must consist of the design parameter to improve, the current value, and the desired or ideal value. Note that circularity improvements can be achieved by applying simultaneous modifications in geometry and materials), and therefore, it is possible to reach higher values than the ideal ones.

4 Case study

The proposed approach is now applied to the circularity redesign of a conventional skateboard. The case study covers the use of supporting data and knowledge and methods and tools proposed in the framework to generate the design specifications for a circular product redesign. Figure 4 shows the exploded view of the skateboard.

4.1 Circularity diagnostic

All calculation parameters and values for product attributes were obtained and calculated for the skateboard. Table B-1 in Appendix B corresponds to the part inventory, while Table 6 summarizes the values for calculating parameters after analyzing the materials, geometry, component inventory, functionalities, and cost of spare parts.

The calculation of each design attribute is described in detail in Appendix B. After that calculation, a relationship between product attribute values and CE strategies can be obtained using a matrix to include the influence of attributes in each strategy. The relationship is measured in three levels: not related (0), related (1), and necessary (2). Once the product attribute value and the relationship value are well defined, they are multiplied and weighted for each CE strategy. Finally, scores of CE strategies were converted to relative values using the maximum possible value for each strategy. Table 7 shows the results of the circularity diagnostic for R1 to R6 for the skateboard.

4.2 Definition of target values

For the case study, all CE strategies are susceptible to improvement. Figure 5 illustrates the graphical representation of the circularity performance through a radial chart. Four improvement scenarios for specific CE strategies are proposed to demonstrate the definition of target values: Repurpose (R6), Repair and Maintenance (R2), Refurbish (R4), and Remanufacture (R5). Each improvement scenario is described in detail in the following subsection.

4.3 Circularity improvement

Once the target values are defined, it is necessary to establish the potential design modifications to enhance the skateboard’s circularity performance. Each one of the improvement scenarios is described as follows, indicating the combination of modifications to increase the circularity performance of each CE strategy. It is necessary to enhance the specific performance of product attributes related to each CE strategy in the relationship matrix of the skateboard to define the potential modifications. Table 8 summarizes the list of potential modifications and the involved product attributes. The list of potential modifications can be obtained by selecting the product attributes and modifying calculation parameters to raise the specific performance for such attributes. Table 9 shows the proposal of modifications for product attributes in each scenario. Finally, the design team must discuss and define the proposal of new values for product attributes. Values in bold in Tables 8 and 9 indicate scenarios with more than one product attribute modification.

With the proposal of new values for product attributes, it is possible to calculate the circularity performance for each CE strategy. Figure 6 summarizes the graphical representation of circularity improvement for the eight CE strategies for each improvement scenario. Table 9 summarizes the modifications, including new values and the corresponding result for each CE strategy (R1–R6). It is possible to observe that improvement scenarios affect the targeted CE strategy and other related strategies based on mutual product attributes.

4.4 Generation of potential redesign modifications

As the final output, it is possible to define a list of redesign modifications to improve the circularity performance of the skateboard. Table 10 lists the parameters to be modified and the ideal value to increase circularity in the R2, R4, R5, and R6 strategies. Such a list of ideal values depends on the product attributes selected in the previous step. Parameters and ideal values are examples of concrete actions by the designer or design team to increase the product’s circularity.

5 Findings and discussion

The proposed approach provides valuable information regarding the overall redesign of products toward a higher circularity performance, considering the eight product attributes identified in the literature. Four attributes were identified as the most influencing factors in the circularity performance of a product: disassemblability, reassemblability, durability, and modularity. Disassemblability and reassemblability were defined in terms of the ease of separating a product into components, which enables repair, refurbishing, remanufacturing, and upgrading of the product. Therefore, these parameters ensure a more circular path of products and components. On the other hand, durability enables the long-lasting path of products based on manufacturing materials and geometric features that ensure the product can be reused. In addition, durability enables repair, refurbishment, remanufacturing, and upgrading, since most durable components serve as core parts with a high-reliability performance that can provide several useful lifetimes. Finally, modularity enables the use of components as modules that can be removed, added, or exchanged to modify the functionalities of any product.

Six CE strategies were considered in the proposed tool: R1 Upgrade, R2 Repair and Maintenance, R3 Reuse, R4 Refurbish, R5 Remanufacture, and R6 Repurpose. However, such strategies are related and co-dependent on product attributes like disassemblability and reassemblability in upgrading, repairing, remanufacturing, and refurbishing. Therefore, any modification of materials or geometry oriented to improve one strategy will indirectly affect the performance of other strategies. This study proposes product circularity as an overall attribute that can be achieved simultaneously through one or more strategies. Circularity performance largely depends on the type of product, the availability of design and manufacturing resources, the sustainability strategy adopted by the designer or manufacturer, the product business model, and the long-term product development plan. Such plans facilitate the identification of which product parameters are vital in guaranteeing a successful enhancement of circularity for multiple lifecycles.

Regarding the existing approaches to measure circularity, the proposed tool addresses some issues and limitations in the previous research approaches. First, it provides a whole measurement of six CE strategies related to the recirculation of parts and products. Second, it enables the measurement of circularity and helps identify which product attributes need to be modified and increased. Finally, it is meant to be easily integrated into engineering design processes, since parameters or modifications can be used to define requirements in the early design stages.

The scoring system proposed was validated and adjusted through the case study. Nevertheless, it is necessary to analyze and discuss the reliability and uncertainty related to the indicator, since it depends on several calculations that can involve some subjectivity. Furthermore, as an improvement opportunity for future works, it would be interesting to run an experiment with different users (practitioners, academics, and designers), similar to the study developed by Saidani et al. (2019a, b), to validate the indicator and the subsequent decision-making process properly.

It is essential to clarify that the circularity diagnostic (step 1) involves the total disassembly of the product. Calculating each product attribute proposed in Table 5 considers an ideal scenario in which products can be fully repaired, and the destruction of pieces during the disassembly is not required. Therefore, the proposed approach fits better with products designed to be disassembled and reassembled without damaging parts. Consequently, the A1 value included in the C1 calculation can be done assuming that it is possible to separate pieces without destruction. In the opposite case, a lower value of A1 is expected and will result in a low performance of C1.

Information about the product (name and identification of parts, materials, and joints) is key to implementing the proposed approach. Therefore, applying the method within a multidisciplinary team is highly recommended to cover mechanical, electronic, electrical, and mechatronic issues during the implementation process. Some parts selected from supplier’s catalogs can involve a lack of information (i.e., bearings). Therefore, deciding whether they are considered in calculating CE product attributes is necessary. In the case study, bearing parts were excluded from the durability, considering it as a part that can be replaced and is not suitable to be modified by the design team.

The improvement directions largely depend on manufacturing companies’ interests, business models, and product types. For example, for products designed and manufactured to have long lifespans without repair interventions, the most suitable strategy is reuse, thus implying high-reliability requirements and a robust design oriented to reducing failure possibilities. Other strategies for products susceptible to changes during their whole lifecycle include repair, refurbishing, remanufacturing, and upgrading. However, such changes need to be supported and enabled by designers and manufacturers, providing protocols and circular supply chains to guarantee the recirculation of products and components from users to the former.

6 Conclusion

This approach proposed a holistic diagnostic tool to measure product circularity based on product attributes related to the six CE strategies involved in recirculating parts and products. Eight attributes were identified from the literature analysis of previous research and were later used to obtain a performance rating for each CE strategy. A case study was developed to demonstrate the implementation process and benefits of the proposed tool. The proposed tool provides an overall evaluation of circularity, enabling the performance in those strategies with higher improvement opportunities through the modification of parameters that define the performance for each strategy.

From the proposed approach, it was demonstrated that product circularity is highly related to disassemblability and reassemblability, which facilitate components’ circularity as independent functional units. In the case study, the circularity diagnostic was essential for identifying which of the CE strategies had the highest performance and which ones implied significant improvement opportunities. Moreover, a deeper analysis can be developed for each CE strategy using more specific data and additional attributes not considered in this article. The proposed metric aims to provide an overall measurement of circularity performance using simple and easy-to-calculate indicators.

The proposed tool is expected to be used by designers, practitioners, and academics interested in product circularity, especially in extended-use lifetime approaches. The improvement of circularity performance was carried out through the definition of scenarios based on a single CE strategy. However, due to the nature and structure of the proposed tool, other strategies can be indirectly improved. In future works, it would be interesting to use additional product attributes related to topics such as economic value, reliability, or environmental performance, as well as the definition of a formal method to identify which improvement scenario is most cost-effective and the implications of a lifecycle perspective for the definition of scenarios in terms of economic and environmental impacts.

As future work, the robustness of the proposed approach will need to be validated through broader studies that include academics, practitioners, and designers to analyze the reliability and uncertainty associated with the calculation of the C1–C8 product attributes and the proposal of improvement actions during the redesign phase.

Data Availability

The authors declare that the data supporting the findings of this study are available within the article.

References

Ackermann L (2018) Design for product care: enhancing consumers’ repair and maintenance activities. Design J 21(4):543–551. https://doi.org/10.1080/14606925.2018.1469331

Aguiar MF, Mesa JA, Jugend D, Pinheiro MAP, Fiorini PDC (2022) Circular product design: strategies, challenges and relationships with new product development. Manage Environ Qual 33(2):300–329. https://doi.org/10.1108/MEQ-06-2021-0125

Albæk JK, Shahbazi S, McAloone TC, Pigosso DCA (2020) Circularity evaluation of alternative concepts during early product design and development. Sustainability (switzerland) 12(22):1–25. https://doi.org/10.3390/su12229353

Allwood JM (2014) Squaring the Circular Economy. In: Handbook of Recycling. Elsevier, pp 445–477. https://doi.org/10.1016/B978-0-12-396459-5.00030-1

Asif FMA, Roci M, Lieder M, Rashid A (2021) A methodological approach to design products for multiple lifecycles in the context of circular manufacturing systems. Clean Prod. https://doi.org/10.1016/j.jclepro.2021.126534

Aziz NA, Wahab DA, Ramli R, Azhari CH (2016) Modelling and optimisation of upgradability in the design of multiple life cycle products: a critical review. J Clean Prod 112:282–290. https://doi.org/10.1016/j.jclepro.2015.08.076

Baines TS, Lightfoot HW, Evans S, Neely A, Greenough R, Peppard J, Roy R, Shehab E, Braganza A, Tiwari A, Alcock JR, Angus JP, Basti M, Cousens A, Irving P, Johnson M, Kingston J, Lockett H, Martinez V et al (2007) State-of-the-art in product-service systems. Proc Inst Mech Eng Part B 221(10):1543–1552. https://doi.org/10.1243/09544054JEM858

Bakker C, Wang F, Huisman J, den Hollander M (2014) Products that go round : exploring product life extension through design. J Clean Prod 69:10–16. https://doi.org/10.1016/j.jclepro.2014.01.028

Bauer T, Zwolinski P, Nasr N, Mandil G (2020) Characterization of circular strategies to better design circular industrial systems. J Remanuf 10(1):L161-176

Bigerna S, Micheli S, Polinori P (2021) New generation acceptability towards durability and repairability of products: circular economy in the era of the 4th industrial revolution. Technol Forecast Soc Change 165:120558

Blomsma F, Pieroni M, Kravchenko M, Pigosso DCA, Hildenbrand J, Rùna A, Kristoffersen E, Shahbazi S, Li J, Wiik C, Due K, Anna-karin J, Mcaloone TC (2019) Developing a circular strategies framework for manufacturing companies to support circular economy-oriented innovation. J Clean Prod 241:118271. https://doi.org/10.1016/j.jclepro.2019.118271

Bocken NMP, de Pauw I, Bakker C, van der Grinten B (2016) Product design and business model strategies for a circular economy. J Ind Prod Eng 33(5):308–320. https://doi.org/10.1080/21681015.2016.1172124

Bracquene E, Peeters JR, Burez J, de Schepper K, Duflou JR, Dewulf W (2019) Repairability evaluation for energy related products. Procedia CIRP 80:536–541. https://doi.org/10.1016/j.procir.2019.01.069

Bracquené E, Peeters J, Alfieri F, Sanfélix J, Duflou J, Dewulf W, Cordella M (2021) Analysis of evaluation systems for product repairability: a case study for washing machines. J Clean Prod 281:125122. https://doi.org/10.1016/j.jclepro.2020.125122

Brissaud D, Zwolinski P (2017) The scientific challenges for a sustainable consumption and production scenario : the circular reuse of materials for the upgrading and repurposing of components. Procedia CIRP 61:663–666. https://doi.org/10.1016/j.procir.2016.11.148

British Standard BS8887–2–2009 Design for Manufacture, Assembly, Disassembly and End-of-life processing (MADE)., (2009)

Burggräf P, Adlon T, Müller K, Föhlisch N, Dackweiler J, Fölling C (2021) Adaptive remanufacturing-methodology towards an intelligent maintenance strategy for production resources. Procedia CIRP 98:330–335. https://doi.org/10.1016/j.procir.2021.01.112

Cao J, Chen X, Wu S, Kumar S (2021) Evolving remanufacturing strategies in China: an evolutionary game theory perspective. Environ Dev Sustain 23(10):14827–14853. https://doi.org/10.1007/s10668-021-01274-7

Cayzer S, Griffiths P, Beghetto V (2017) Design of indicators for measuring product performance in the circular economy. Int J Sustain Eng 10(4–5):289–298. https://doi.org/10.1080/19397038.2017.1333543

Chen YT, Chan FTS, Chung SH, Park WY (2018) Optimization of product refurbishment in closed-loop supply chain using multi-period model integrated with fuzzy controller under uncertainties. Robot Comput-Integrat Manuf 50:1339–1351. https://doi.org/10.1016/j.rcim.2017.05.005

Chouinard U, Pigosso DCA, McAloone TC, Baron L, Achiche S (2019) Potential of circular economy implementation in the mechatronics industry: an exploratory research. J Clean Prod. https://doi.org/10.1016/j.jclepro.2019.118014

Chunhua F, Shi H, Guozhen B (2020) A group decision making method for sustainable design using intuitionistic fuzzy preference relations in the conceptual design stage. J Clean Prod 243:118640. https://doi.org/10.1016/j.jclepro.2019.118640

Cooper DR, Gutowski TG (2017) The environmental impacts of reuse: a review. J Ind Ecol 21(1):38–56. https://doi.org/10.1111/jiec.12388

Cordella M, Al F, Clemm C, Berwald A (2021) Durability of smartphones: a technical analysis of reliability and repairability aspects. J Clean Prod 286:125388. https://doi.org/10.1016/j.jclepro.2020.125388

Coughlan D, Fitzpatrick C, Mcmahon M (2018) Repurposing end of life notebook computers from consumer WEEE as thin client computers e A hybrid end of life strategy for the Circular Economy in electronics. J Clean Prod 192:809–820. https://doi.org/10.1016/j.jclepro.2018.05.029

de Almeida ST, Borsato M, Lie Ugaya CM (2017) Application of exergy-based approach for implementing design for reuse: the case of microwave oven. J Clean Prod 168:876–892. https://doi.org/10.1016/j.jclepro.2017.09.034

de los Rios IC, Charnley FJS (2017) Skills and capabilities for a sustainable and circular economy: The changing role of design. J Clean Prod 160:109–122. https://doi.org/10.1016/j.jclepro.2016.10.130

den Hollander MC, Bakker CA, Hultink EJ (2017) Product design in a circular economy: development of a typology of key concepts and terms. J Ind Ecol 21(3):517–525. https://doi.org/10.1111/jiec.12610

di Maio F, Rem PC (2015) A robust indicator for promoting circular economy through recycling. J Environ Prot 06(10):1095–1104. https://doi.org/10.4236/jep.2015.610096

Ellen MacArthur Foundation (2015) Towards a circular economy: business rationale for an accelerated transition. Ellen MacArthur Foundation (EMF), p 20

Evans JL and Bocken N (2014) A tool for manufacturers to find opportunity in the circular economy—www.circulareconomytoolkit.org. SDM 2014, International Conference on Sustainable Design and Manufacturing 28, 29 and 30 April 2014 Cardiff, Wales, UK, http://Sdm-14.Kesinternational.Org/

Ellen MacArthur Foundation - EMAF (2015) Circularity indicators—an approach to measure circularity. Methodology and project overview

Franco MA (2019) A system dynamics approach to product design and business model strategies for the circular economy. J Clean Prod 241:118327. https://doi.org/10.1016/j.jclepro.2019.118327

Franklin-Johnson E, Figge F, Canning L (2016) Resource duration as a managerial indicator for Circular Economy performance. J Clean Prod 133:589–598. https://doi.org/10.1016/j.jclepro.2016.05.023

Geng J, Tian X, Bai M, Jia X, Liu X (2014) Computers in Industry A design method for three-dimensional maintenance, repair and overhaul job card of complex products. Comput Ind 65(1):200–209. https://doi.org/10.1016/j.compind.2013.08.008

Go TF, Wahab DA, Hishamuddin H (2015) Multiple generation lifecycles for product sustainability: the way forward. J Clean Prod 95:16–29. https://doi.org/10.1016/j.jclepro.2015.02.065

Haines-Gadd M, Chapman J, Lloyd P, Mason J, Aliakseyeu D (2018) Emotional durability design Nine-A tool for product longevity. Sustainability (switzerland) 10(6):1–19. https://doi.org/10.3390/su10061948

Haupt M, Vadenbo C, Hellweg S (2016) Do we have the right performance indicators for the circular economy? Insight into the swiss waste management system. J Indust Ecol 21:1–13. https://doi.org/10.1111/jiec.12506

Haziri LL and Sundin E (2020) Supporting design for remanufacturing—a framework for implementing information feedback from remanufacturing to product design. 57–76

Hebrok M (2014) Design for longevity: taking both the material and social aspects of product-life into account. J Des Res 12(3):204–220. https://doi.org/10.1504/JDR.2014.064232

Ishigami Y, Yagi H, Kondoh S, Umeda Y, Shimomura Y and Yoshioka M (2008) Development of a design methodology for upgradability involving changes of functions. 0769520484, 235–242https://doi.org/10.1109/vetecf.2003.240538

Kaddoura M, Kambanou ML, Tillman AM, Sakao T (2019) Is prolonging the lifetime of passive durable products a low-hanging fruit of a circular economy? A multiple case study. Sustainability (switzerland). https://doi.org/10.3390/su11184819

Kampker A, Wessel S, Fiedler F, Maltoni F (2021) Battery pack remanufacturing process up to cell level with sorting and repurposing of battery cells. J Remanufactur. https://doi.org/10.1007/s13243-020-00088-6

Kelly JT, Reff A, Gantt B (2017) A method to predict PM2.5 resulting from compliance with national ambient air quality standards. Atmos Environ 162:1–10. https://doi.org/10.1016/j.atmosenv.2017.05.009

Khan MA, Mittal S, West S, Wuest T (2018) Review on upgradability—a product lifetime extension strategy in the context of product service systems. J Clean Prod 204:1154–1168. https://doi.org/10.1016/j.jclepro.2018.08.329

Krystofik M, Luccitti A, Parnell K, Thurston M (2018) Adaptive remanufacturing for multiple lifecycles: A case study in office furniture. Resour Conserv Recycl 135:14–23. https://doi.org/10.1016/j.resconrec.2017.07.028

Kwak M, Kim HM (2011) Assessing product family design from an end-of-life perspective. Eng Optim 43(3):233–255. https://doi.org/10.1080/0305215X.2010.482990

Laitala K, Klepp IG, Haugrønning V, Throne-holst H (2021) Increasing repair of household appliances, mobile phones and clothing: experiences from consumers and the repair industry. J Clean Prod 282:125349. https://doi.org/10.1016/j.jclepro.2020.125349

Li Y, Xue D, Gu P (2008) Design for product adaptability. Concurr Eng Res Appl 16(3):221–232. https://doi.org/10.1177/1063293X08096178

Manelius A, Nielsen S, Kauschen JS (2019) Rebeauty – artistic strategies for repurposing material components rebeauty – artistic strategies for repurposing material components. IOP Conf Ser. https://doi.org/10.1088/1755-1315/225/1/012023

Mesa J, Maury H, Arrieta R, Bula A, Riba C (2015) Characterization of modular architecture principles towards reconfiguration: a first approach in its selection process. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-015-6951-3

Mesa JA, Esparragoza I, Maury H (2017) Development of a metric to assess the complexity of assembly/disassembly tasks in open architecture products. Int J Prod Res 7543(November):1–19. https://doi.org/10.1080/00207543.2017.1398431

Mesa J, González-quiroga A, Maury H (2020) Developing an indicator for material selection based on durability and environmental footprint: a circular economy perspective. Resour Conserv Recycling 160:104887. https://doi.org/10.1016/j.resconrec.2020.104887

Mesa JA, Gonzalez-Quiroga A, Aguiar MF, Jugend D (2022) Linking product design and durability: a review and research agenda. Heliyon 8(9):e10734. https://doi.org/10.1016/j.heliyon.2022.e10734. (Elsevier Ltd)

Mestre A, Cooper T (2017) Circular product design. A multiple loops life cycle design approach for the circular economy. Design J 20(sup1):S1620–S1635. https://doi.org/10.1080/14606925.2017.1352686

Moreno M, de los Rios C, Rowe Z, Charnley F (2016) A conceptual framework for circular design. Sustainability (switzerland). https://doi.org/10.3390/su8090937

Nurhasyimah AA, Dzuraidah AW, Rizauddin R (2016) Evaluating Design for upgradability at the conceptual design stage. Jurlna Teknologi 78(6–9):37–43

Offerman E (2019) Critical materials: underlying causes and sustainable mitigation strategies. World Scientific

Park JY, Chertow MR (2014) Establishing and testing the “reuse potential” indicator for managing wastes as resources. J Environ Manage 137:45–53. https://doi.org/10.1016/j.jenvman.2013.11.053

Pérez-Martínez MM, Carrillo C, Rodeiro-Iglesias J, Soto B (2021) Life cycle assessment of repurposed waste electric and electronic equipment in comparison with original equipment. Sustain Prod Consum 27:1637–1649. https://doi.org/10.1016/j.spc.2021.03.017

Pialot O, Millet D (2014) Why upgradability should be considered for rationalizing materials? Procedia CIRP 15:379–384. https://doi.org/10.1016/j.procir.2014.06.013

Raihanian A, Esmaeilian B, Cade W, Wiens K, Behdad S (2016) Mining consumer experiences of repairing electronics: product design insights and business lessons learned. J Clean Prod 137:716–727. https://doi.org/10.1016/j.jclepro.2016.07.144

ResCom Consortium (2021) ResCoM-Resource Conservative Manufacturing Project. The ResCoM platform and tools. https://www.rescoms.eu/platform-and-tools.html

Saidani M, Cluzel F, Leroy Y, Yannou B (2019a) Testing the robustness of circularity indicators: empirical insights from workshops on an industrial product. Proc Design Soc 1(1):3401–3410. https://doi.org/10.1017/dsi.2019.347

Saidani M, Yannou B, Leroy Y, Cluzel F (2020) Dismantling, remanufacturing and recovering heavy vehicles in a circular economy—technico-economic and organisational lessons learnt from an industrial pilot study. Resour Conserv Recycling 156(November 2018):104684. https://doi.org/10.1016/j.resconrec.2020.104684

Saidani M, Kim H, Yannou B and Cluzel F (2019b) C-indicators: a web-based platform to monitor and improve the circularity potential of products. ASME 2019b International Design Engineering Technical Conferences and Computers and Information in Engineering Conference IDETC/CIE2019b Aug 2019b, Anaheim, California, United States. Hal-02270137f, 23(5). https://doi.org/10.1111/jiec.12852

Shahbazi S, Jönbrink AK (2020) Design guidelines to develop circular products: action research on nordic industry. Sustainability (switzerland) 12(9):1–14. https://doi.org/10.3390/su12093679

Singhal D, Tripathy S, Kumar S (2020) Remanufacturing for the circular economy: study and evaluation of critical factors. Resour Conserv Recycling 156(August 2018):104681. https://doi.org/10.1016/j.resconrec.2020.104681

Sumter D, Bakker C, Balkenende R (2018) The role of product design in creating circular business models: a case study on the lease and refurbishment of baby strollers. Sustainability (switzerland). https://doi.org/10.3390/su10072415

Talens Peiró L, Ardente F, Mathieux F (2017) Design for disassembly criteria in EU product policies for a more circular economy: a method for analyzing battery packs in PC-Tablets and subnotebooks. J Ind Ecol 21(3):731–741. https://doi.org/10.1111/jiec.12608

Türkeli S, Huang B, Stasik A, Kemp R (2019) Circular economy as a glocal business activity: mobile phone repair in the Netherlands, Poland and China. Energies. https://doi.org/10.3390/en12030498

van Nes N, Cramer J (2005) Influencing product lifetime through product design. Bus Strateg Environ 14(5):286–299. https://doi.org/10.1002/bse.491

Vezzoli C, Manzini E (2008) Design for environmental sustainability. Design Environ Sustain. https://doi.org/10.1007/978-1-84800-163-3

Wagner E, Bracquen E, Jaeger-erben M (2021) Exploring 14 years of repair records e information retrieval, analysis potential and data gaps to improve reparability. J Clean Prod 281:125259. https://doi.org/10.1016/j.jclepro.2020.125259

Yang SS, Ong SK, Nee AYC (2016) A decision support tool for product design for remanufacturing. Procedia CIRP 40:144–149. https://doi.org/10.1016/j.procir.2016.01.085

Yang SS, Nasr N, Ong SK, Nee AYC (2017) Designing automotive products for remanufacturing from material selection perspective. J Clean Prod 153:570–579. https://doi.org/10.1016/j.jclepro.2015.08.121

Zacho KO, Bundgaard AM, Mosgaard MA (2018) Constraints and opportunities for integrating preparation for reuse in the Danish WEEE management system. Resour Conserv Recycl 138:13–23. https://doi.org/10.1016/j.resconrec.2018.06.006

Zink T, Maker F, Geyer R, Amirtharajah R, Akella V (2014) Comparative life cycle assessment of smartphone reuse: repurposing vs. refurbishment. Int J Life Cycle Assess 19(5):1099–1109. https://doi.org/10.1007/s11367-014-0720-7

Funding

Open Access funding provided by Colombia Consortium.

Author information

Authors and Affiliations

Contributions

JAM: conceptualization, methodology, and software. AG-Q, JAM: data curation and writing—original draft preparation. JAM: visualization and investigation. AG-Q: supervision, software, and validation. JAM: writing—reviewing and editing,

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Indicators/metrics for product attributes in circular products

1.1 Detailed definition of calculation parameters C1, C2 and C7

1.1.1 C1 reassemblability

1.1.2 C2 durability

1.1.2.1 Geometrical durability

See Table 13.

1.1.2.2 Material durability

1.1.3 C7 Relative cost of spare parts

See Table 16.

Appendix B: Detailed calculation of design parameters

See Table 17.

2.1 C1 reassemblability

For the Skateboard NR = N. Thus, the product can be separated or disassembled in all their pieces without restriction. Therefore, the disassemblability R1 = 1.00

For the skateboard, disassembly tasks can be performed using the conventional tools. Therefore, the value corresponds to a “Good” easiness. R2 = 0.80

For the skateboard, all disassembly tasks are fully reversible (100%). Therefore, the value corresponds to a “Excellent” reversibility. R3 = 1.00

Calculation of reassemblability is

2.2 C2 durability

2.2.1 Geometrical durability

The value for Geometrical Durability is calculated by averaging the stress concentration score between SC1 (1), SC2 (1), and SC3 (0.5)

2.2.2 Material durability

See Table 18.

After Chemical and Mechanical durabilities are calculated, it is necessary to obtain its relative value with respect to 1. After that, the average of both values represents the Material Durability

Once Geometrical and Material Durability are calculated, such values are averaged to obtain the Durability value. For the skateboard, the durability is equal to 0.80

2.3 C3 modularity

Modularity is calculated as the ratio between the number of parts that can be considered as a module (M) and the total number of parts (P). For the skateboard M = 10 and P = 11

2.4 C4 simplicity (part variety)

Complexity is measured in terms of product’s simplicity. Thus, the calculation is based on the number of pieces (N) and the total number of parts (P). For the skateboard, N = 47, and P = 11

2.5 C5 standardization

Standardization is measured in terms of the number of standardized parts (S) and the total number of parts (P). For the skateboard, S = 6, and P = 11

2.6 C6 commonality

Commonality is measured in terms of the number of parts that are common within the product family (C) and the total number of parts (P). For the skateboard, C = 8 (nuts, screws, bearings), and P = 11

2.7 C7 relative cost of spare parts

In the case of the skateboard, the overrun is approximately 25%. Therefore, the score for cost of spare parts is 0.6

2.8 C8 secondary functions defined from design

In the case of the skateboard, no additional or secondary functions were defined from design

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mesa, J.A., González-Quiroga, A. Development of a diagnostic tool for product circularity: a redesign approach. Res Eng Design 34, 401–420 (2023). https://doi.org/10.1007/s00163-023-00415-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00163-023-00415-5