Abstract

We analyze in this contribution the propagation of bulk and Rayleigh surface waves in periodic architectured materials undergoing internal damage. An elastic damageable continuum-based model is developed in the framework of the thermodynamics of irreversible processes, whereby the displacement experiences a jump across the faces of the propagating crack. The crack propagation involves an enhancement of the displacement field associated with embedded discontinuities, which remain localized within each (triangular type) finite element. The displacement discontinuity is regulated by the traction separation behavior described by an exponential cohesive model with damage hardening followed by softening. The effective mechanical properties of the overall network are evaluated versus the increasing damage. The phase velocities for the longitudinal and transverse modes are then computed continuously versus the amount of damage, considering successively the situations of symmetrically and unsymmetrically distributed damage occurrence and propagation. Simulation results show that although the crack pattern is different in these two situations, it has no impact on the evolution of the effective moduli versus global damage. The phase velocities computed based on the effective moduli decrease as damage propagates within the network; thus, it is an indicator of the amount of global damage.

Similar content being viewed by others

References

Wicks, N., Hutchinson, J.W.: Optimal truss plates. Int. J. Solids Struct. 38(30–31), 5165–5183 (2001)

Arabnejad, S., Johnston, R.B., Ann, J., Singh, B., Tanzer, M., Pasini, D.: High-strength porous biomaterials for bone replacement: a strategy to assess the interplay between cell morphology, mechanical properties, bone ingrowth and manufacturing constraints. Acta Biomater. 30, 345–356 (2016)

Chen, W.F.: Structural Engineering Handbook-Space Frame Structures, 3rd edn. ASME Press, New York (2000)

Heinl, P., Mu, L., Ko, C., Singer, R.F., Mu, F.A.: Cellular Ti–6Al–4V structures with interconnected macro porosity for bone implants fabricated by selective electron beam melting. Acta Biomater. 4(2), 1536–1544 (2008)

Yang, L., Harrysson, O., West, H., Cormier, D.: Mechanical properties of 3D re-entrant honeycomb auxetic structures realized via additive manufacturing. Int. J. Solids Struct. 69, 475–490 (2015)

Yang, L.: A study about size effects of 3D periodic cellular structures. In: Proceedings of the 27th Annual International Solid Freeform Fabrication (SFF) Symposium, Austin, TX (2016)

Simone, A.E., Gibson, L.J.: Effects of solid distribution on the stiffness and strength of metallic foams. Acta Mater. 46(6), 2139–2150 (1998)

Jin, I., Kenny, L.D., Sang, H.: U.S. patent no. 4, 973, 358, Washington, DC, U.S. Patent and Trademark Office (1990)

Xiaoyu, Z., Howon, L., Todd, H.W., Maxim, S., Joshua, D., Eric, B.D., Joshua, D.K., Monika, M.B., Qi, G., Julie, A.J., Sergei, O.K., Nicholas, X.F., Christopher, M.S.: Ultralight, ultrastiff mechanical metamaterials. Science 344(6190), 1373–1377 (2014)

Maiti, S.K., Gibson, L.J., Ashby, M.F.: Deformation and energy absorption diagrams for cellular solids. Acta Metall. 32(4), 1963–1975 (1984)

Wang, A.-J., McDowell, D.L.: In-plane stiffness and yield strength of periodic metal honeycombs. J. Eng. Mater. Technol. 126(1), 137–156 (2004)

Wallach, J.C., Gibson, L.J.: Mechanical behavior of a three-dimensional truss material. Int. J. Solids Struct. 38(40–41), 7181–7196 (2001)

Deshpande, V.S., Fleck, N.A., Ashby, M.F.: Effective properties of the octet-truss lattice material. J. Mech. Phys. Solids 49(3), 1747–1769 (2001)

Wu, Y., Yang, L.: The effect of unit cell size and topology on tensile failure behavior of 2D lattice structures. Int. J. Mech. Sci. 170, 105342 (2020)

Yan, C., Hao, L., Hussein, A., Young, P., Raymont, D.: Advanced lightweight 316L stainless steel cellular lattice structures fabricated via selective laser melting. Mater. Des. 55, 533–541 (2014)

Smith, M., Guan, Z., Cantwell, W.J.: Finite element modelling of the compressive response of lattice structures manufactured using the selective laser melting technique. Int. J. Mech. Sci. 67, 28–41 (2013)

Li, S.J., Murr, L.E., Cheng, X.Y., Zhang, Z.B., Hao, Y.L., Yang, R., Medina, F., Wicker, R.B.: Compression fatigue behavior of Ti–6Al–4V mesh arrays fabricated by electron beam melting. Acta Mater. 60(3), 793–802 (2012)

Deshpande, V.S., Ashby, M.F., Fleck, N.A.: Foam topology: bending versus stretching dominated architectures. Acta Mater. 49(6), 1035–1040 (2001)

Yang, L., Harrysson, O., West, H., Cormier, D.: Modeling of uniaxial compression in a 3D periodic re-entrant lattice structure. J. Mater. Sci. 48(4), 1413–1422 (2013)

Carneiro, V.H., Meireles, J., Puga, H.: Auxetic materials: a review. Mater. Sci. Poland 31(4), 561–571 (2013)

Gibson, L.J., Ashby, M.F.: Cellular Solids: Structure and Properties. Cambridge University Press, Cambridge (1999)

Ashby, M.F.: The properties of foams and lattices, philosophical transactions of the royal society A: mathematical. Phys. Eng. Sci. 364(1838), 15–30 (2005)

Goda, I., Ganghoffer, J.F.: 3D plastic collapse and brittle fracture surface models of trabecular bone from asymptotic homogenization method. Int. J. Eng. Sci. 87, 58–82 (2015)

Goda, I., Ganghoffer, J.F.: Construction of the effective plastic yield surfaces of vertebral trabecular bone under twisting and bending moments stresses using a 3D microstructural model. ZAMM J. Appl. Math. Mech. 97(3), 254–272 (2017)

Fleck, N.A., Qiu, X.M.: The damage tolerance of elastic-brittle, two-dimensional isotropic lattices. J. Mech. Phys. Solids. 55(3), 562–588 (2007)

Quintana-Alonso, I., Fleck, N.A.: Fracture of Brittle Lattice Materials: A Review, Major Accomplishments in Composite Materials and Sandwich Structures, pp. 799–816 (2010)

Silva, M.J., Gibson, L.J.: The effects of non-periodic microstructure and defects on the compressive strength of two-dimensional cellular solids. Int. J. Mech. Sci. 39(2), 549–563 (1997)

Albuquerque, J.M., Vaz, M.F., Fortes, M.A.: Effect of missing walls on the compression behaviour of honeycombs. Scr. Mater. 41(1), 167–174 (1999)

Guo, X.E., Gibson, L.J.: Behavior of intact and damaged honeycombs: a finite element study. Int. J. Mech. Sci. 41(1), 85–105 (1999)

Oliver, J., Huespe, A.E., Sanchez, P.J.: A comparitive study on finite elements for capturing strong discontinuities: E-FEM versus X-FEM. Comput. Methods Appl. Mech. Eng. 195(37–40), 4732–4752 (2006)

Luenberger, D.G.: Linear and Nonlinear Programming. Addison-Wesley, Reading (1984)

Strang, G.: Introduction to Applied Mathematics. Wellesley-Cambridge Press, Cambridge (1986)

Lemaitre, J.: A Course on Damage Mechanics. Springer, New York (1992)

Armero, F.: Localized anisotropic damage of brittle materials. In: Onate, E., Owen, D.R.J., Hinton, E. (eds.) Computational Plasticity, Fundamentals and Applications, pp. 635–640. CIMNE, Barcelona (1997)

Do, X.N., Ibrahimbegovic, A., Brancherie, D.: Dynamics framework for 2D anisotropic continuum-discrete damage model for progressive localized failure of massive structures. Comput. Struct. 183, 14–26 (2017)

Ibrahimbegovic, A., Kozar, I.: Non-linear Wilson’s brick element for finite elastic deformations of three-dimensional solids. Commun. Numer. Methods Eng. 11(3), 655–664 (1995)

Brancherie, D.: Modèles continus et “discrets” pour les problèmes de localisation et de rupture fragile et/ou ductile. PhD Thesis, École Normale Supérieure de Cachan, France (2003)

Brancherie, D., Ibrahimbegovic, A.: Novel anisotropic continuum-discrete damage model capable of representing localized failure of massive structures: part I—theoretical formulation and numerical implementation. Eng. Comput. Int. J. Comput. Aided Eng. 26, 100–127 (2009)

Simo, J.C., Rifai, M.S.: A class of mixed assumed strain methods and the method of incompatible modes. Int. J. Numer. Methods Eng. 29(3), 1595–1638 (1990)

Ibrahimbegovic, A., Wilson, E.L.: A modified method of incompatible modes. Commun. Appl. Numer. Methods 7(3), 187–194 (1991)

Ibrahimbegovic, A.: Nonlinear Solid Mechanics: Theoretical Formulations and Finite Element Solution Methods. Springer, Berlin (2009)

Goda, I., Assidi, M., Belouettar, S., Ganghoffer, J.F.: A micropolar anisotropic constitutive model of cancellous bone from discrete homogenization. J. Mech. Behav. Biomed. Mater. 16, 87–108 (2012)

Ganghoffer, J.F., Goda, I.: Prediction of Size Effects in Bone Brittle and Plastic Collapse, Multiscale Biomechanics, pp. 345–388 (2018)

Ganghoffer, J.F., Goda, I.: Micropolar Models of Trabecular Bone, Multiscale Biomechanics, pp. 263–316 (2018)

Goda, I., Rahouadj, R., Ganghoffer, J.F.: Size dependent static and dynamic behavior of trabecular bone based on micromechanical models of the trabecular architecture. Int. J. Eng. Sci. 72, 53–77 (2013)

Goda, I., Ganghoffer, J.F., Czarnecki, S., Czubacki, R., Wawruch, P.: Topology optimization of bone using cubic material design and evolutionary methods based on internal remodeling. Mech. Res. Commun. 95, 52–60 (2019)

Ganghoffer, J.F., Goda, I., Rahouadj, R.: Size-Dependent Dynamic Behavior of Trabecular Bone, Multiscale Biomechanics, pp. 317–344 (2018)

Goda, I., Ganghoffer, J.F.: Modeling of anisotropic remodeling of trabecular bone coupled to fracture. Arch. Appl. Mech. 88(5), 2101–2121 (2018)

Goda, I., Ganghoffer, J.F.: Identification of couple-stress moduli of vertebral trabecular bone based on the 3D internal architectures. J. Mech. Behav. Biomed. Mater. 51, 99–118 (2015)

Goda, I., Assidi, M., Ganghoffer, J.F.: A 3D elastic micropolar model of vertebral trabecular bone from lattice homogenization of the bone microstructure. Biomech. Model. Mechanobiol. 13(1), 53–83 (2014)

ElNady, K., Goda, I., Ganghoffer, J.F.: Computation of the effective nonlinear mechanical response of lattice materials considering geometrical nonlinearities. Comput. Mech. 58(6), 957–979 (2016)

Geuzaine, C., Remacle, J.F.: Gmsh: a 3-D finite element mesh generator with built-in pre- and post-processing facilities. Int. J. Numer. Methods Eng. 79(4), 1309–1331 (2009)

Taylor, R.: FEAP: Finite Element Analysis Program, University of California, Berkeley (2011)

Tanwer, A.K.: Effect of various heat treatment processes on mechanical properties of mild steel and stainless steel. Am. Int. J. Res. Sci. Technol. Eng. Math. 8(1), 57–61 (2014)

Mead, D.J.: Wave propagation in continuous periodic structures: research contributions from Southampton, 1964–1995. J. Sound Vib. 190(3), 495–524 (1996)

Langley, R.S., Bardell, N.S., Ruivo, H.M.: The response of two-dimensional periodic structures to harmonic point loading: a theoretical and experimental study of a beam grillage. J. Sound Vib. 207(4), 521–535 (1997)

Phani, A.S., Woodhouse, J., Fleck, N.A.: Wave propagation in two-dimensional periodic lattices. J. Acoust. Soc. Am. 119(4), 1995–2005 (2006)

Gonella, S., Ruzzene, M.: Analysis of in-plane wave propagation in hexagonal and reentrant lattices. J. Sound Vib. 312(1–2), 125–139 (2008a)

Gonella, S., Ruzzene, M.: Homogenization and equivalent in-plane properties of two-dimensional periodic lattices. Int. J. Solids Struct. 45(10), 2897–2915 (2008b)

Bacigalupo, A., Gambarotta, L.: Homogenization of periodic hexa- and tetrachiral cellular solids. Compos. Struct. 116, 461–476 (2014)

Reda, H., Rahali, Y., Ganghoffer, J.F., Lakiss, H.: Wave propagation in 3D viscoelastic auxetic and textile materials by homogenized continuum micropolar models. Compos. Struct. 141, 328–345 (2016a)

Reda, H., Rahali, Y., Ganghoffer, J.F., Lakiss, H.: Analysis of dispersive waves in repetitive lattices based on homogenized second-gradient continuum models. Compos. Struct. 152, 712–728 (2016b)

Brillouin, L.: Wave Propagation in Periodic Structures. Dover, New York (1946)

Chen, W., Fish, J.: A dispersive model for wave propagation in periodic heterogeneous media based on homogenization with multiple spatial and temporal scales. J. Appl. Mech. 68(1), 153–161 (2001)

Liu, Z., Zhang, X., Mao, Y., Zhu, Y.Y., Yang, Z., Chan, C.T., Sheng, P.: Locally resonant sonic materials. Science 289(5485), 1734–1736 (2000)

Goffaux, C., Sánchez-Dehesa, J., Yeyati, A.L., Lambin, P., Khelif, A., Vasseur, J.O., Djafari-Rouhani, B.: Evidence of fano-like interference phenomena in locally resonant materials. Phys. Rev. Lett. 88(13), 225502 (2002)

Wang, G., Wen, X., Wen, J., Shao, L., Liu, Y.: Observation of electron-antineutrino disappearance at Daya Bay. Phys. Rev. Lett. 154302 (2004)

Guenneau, S., Movchan, A., Pétursson, G., Ramakrishna, S.A.: Acoustic metamaterials for sound focusing and confinement. New J. Phys. 9(4), 399 (2007)

Pennec, Y., Djafari-Rouhani, B., Larabi, H., Vasseur, J.O., Hladky-Hennion, A.C.: Low-frequency gaps in a phononic crystal constituted of cylindrical dots deposited on a thin homogeneous plate. Phys. Rev. B 78(10), 104105 (2008). (n.d.)

Wu, T.T., Huang, Z.G., Lin, S.: Surface and bulk acoustic waves in two-dimensional phononic crystal consisting of materials with general anisotropy. Phys. Rev. B 69, 094301 (2004)

Torrent, D., Sanchez-Dehesa, J.: Acoustic cloaking in two dimensions: a feasible approach. New J. Phys. 10(6), 063015 (2008)

Merheb, B., Deymier, P.A., Muralidharan, K., Bucay, J., Jain, M., Aloshyna-Lesuffleur, M., Greger, R.W., Mohanty, S., Berker, A.: Viscoelastic effect on acoustic band gaps in polymer-fluid composites. Model. Simul. Mater. Sci. Eng. 17(7), 075013 (2009)

Bacigalupo, A., De Bellis, M.L.: Auxetic anti-tetrachiral materials: equivalent elastic properties and frequency band-gaps. Compos. Struct. 131, 530–544 (2015)

Pham, C.V., Ogden, R.W.: Formulas for the Rayleigh wave speed in orthotropic elastic solids. Arch. Mech. 56(3), 247–265 (2004)

Wang, A.-J., McDowell, D.L.: Effects of defects on in-plane properties of periodic metal honeycombs. Int. J. Mech. Sci. 45(4), 1799–1813 (2003)

Imberger, J.: Surface waves, In: Environmental Fluid Dynamics: Flow Processes, Scaling, Equations of Motion, and Solutions to Environmental Flows, Academic Press, New York, pp. 333–349 (2012)

Melville, W.K.: Surface gravity and capillary waves. In: Encyclopedia of Ocean Sciences, 2nd edn, Elsevier, Amsterdam, pp. 573–581 (2001)

Haldar, S.K.: Exploration geophysics. In: Mineral Exploration: Principles and Applications, Elsevier, Amsterdam, pp. 103–122 (2018)

Al Wardany, R., Rhazi, J., Ballivy, G., Gallias, J.L., Saleh, K.: Use of Rayleigh wave methods to detect near surface concrete damage. In: 16th WCNDT (2004)

Stokoe, K.H., Santamarina, J.C.: Seismic-Wave-based Testing in Geotechnical Engineering, vol. 2000, GeoEng, Melbourne, Australia, pp. 1490–1536 (2000)

Dascalu, C.: Dynamic localization of damage and microstructural length influence. Int. J. Damage Mech. 26(3), 1–29 (2016)

Ganghoffer, J.F., Goda, I.: Multiscale Aspects of Bone Internal and External Remodeling, Multiscale Biomechanics, pp. 389–435 (2018)

Ganghoffer, J.F., Goda, I.: A combined accretion and surface growth model in the framework of irreversible thermodynamics. Int. J. Eng. Sci. 127, 53–79 (2018)

Goda, I., Ganghoffer, J.F., Maurice, G.: Combined bone internal and external remodeling based on Eshelby stress. Int. J. Solids Struct. 94, 138–157 (2016)

Hazelwood, S.J., Martin, R.B., Rashid, M.M., Rodrigo, J.J.: A mechanistic model for internal bone remodeling exhibits different dynamic responses in disuse and overload. J. Biomech. 34, 299–308 (2001)

Ganghoffer, J.F.: A contribution to the mechanics and thermodynamics of surface growth. Application to bone external remodeling. Int. J. Eng. Sci. 50, 166–191 (2012)

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Andreas Öchsner.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Computation of the effective properties

In general, the computation of the effective moduli of a Y-shape unit cell (with the dimensions as in Fig. 24), which is in turn subjected to the homogeneous displacement-controlled tension \(({}^{{u}_{xx}}/ 2)\) along the X-direction, the homogeneous displacement-controlled tension \(\left( u_{yy} \right) \) in the Y-direction, and the homogeneous displacement-controlled shearing \(\left( u_{yx} \right) \) case shown in Fig. 9, is separately treated as follows:

-

In case the sample is loaded in tension by homogeneous displacements \(({}^{{u}_{xx}}/2)\), the effective modulus is computed as: \(E_{xx}=\frac{\sigma _{xx}}{\varepsilon _{xx}}\) with \(\sigma _{xx}=\frac{\left| R_{x,2} \right| }{h}\), and \(\varepsilon _{xx}=\frac{u_{xx}}{L}\)

The corresponding Poisson’s ratio can be easily defined as: \(\upsilon _{xy}=-\frac{\frac{u_{y,\mathrm{node} \,{{\varvec{c}}}}}{H}}{\varepsilon _{xx}} =-\frac{u_{y,\mathrm{node}\,{{\varvec{c}}}}}{H\varepsilon _{xx}}\)

where \(\sigma _{xx}\) is the stress, \(\varepsilon _{xx}\) refers to the strain, \(R_{x,2}\) denotes the total reaction force at nodes on the right edge of the unit cell where displacements \({}^{u_{xx}}/ 2\) are imposed, and \(u_{y,\mathrm{node}\,{{\varvec{c}}}}\) stands for the measured displacement in the Y-direction at node c.

-

Similarly, when homogeneous displacements \(\left( u_{yy} \right) \) are applied to the specimen the value of the effective modulus is \(E_{yy}=\frac{\sigma _{yy}}{\varepsilon _{yy}}\) with \(\sigma _{yy}=\frac{\left| R_{y} \right| }{2l}\) and \(\varepsilon _{yy}=\frac{u_{yy}}{H}\).

Meanwhile, \(\upsilon {}_{yx}=-\frac{\frac{u_{x,\mathrm{node}\,{{\varvec{a}}}}-u_{x,\mathrm{node}\,{{\varvec{b}}}}}{L}}{\varepsilon _{yy}}=-\frac{u_{x,\mathrm{node}\,{{\varvec{a}}}}-u_{x,\mathrm{node}\,{{\varvec{b}}}}}{L\varepsilon _{yy}}\) is the expression of the Poisson’s ratio in this case, wherein \(\sigma _{yy}\) is the stress, \(\varepsilon _{yy}\) is the strain, \(R_{y}\) is referred to the sum of reaction forces in the Y-direction at the support points, and \(u_{x,\mathrm{node}\,{{\varvec{a}}}},u_{x,\mathrm{node}\,{{\varvec{b}}}}\) represent the measured displacement in the X-direction at node a and b, respectively.

-

In the last case in which the imposed loads are the homogeneous displacement-controlled shearing \(\left( u_{yx} \right) \), the effective shear modulus can be written as: \(G_{yx}=\frac{\tau _{yx}}{\varepsilon _{yx}}\) with \(\tau _{yx}=\frac{\left| R_{x,1} \right| }{2l}\), \(\varepsilon _{yx}=\frac{u_{yx}}{H}\), wherein \(\tau _{yx}\) is the shear stress, \(\varepsilon _{yx}\) is the shear strain, and \(R_{x,1}\) is the sum of reaction forces in the X-direction at the support points.

Finally, we obtain the full rigidity matrix as follows:

Appendix 2: Implementation of periodicity conditions

The finite element model is capable of simulating elementary cells under combined loading conditions. Based upon the relation between the strain energy of the microstructure and that of the homogenized equivalent model under specific periodic boundary conditions, a strain energy-based method is developed. This method is then used to compute the effective elastic properties. The heterogeneity within the unit cell of the repetitive architectured material is taken into account through the homogenized material properties.

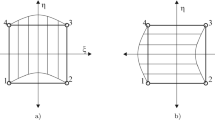

At the meso-level, the finite element modeling procedure accounts for a single unit cell instead of the entire structure. By imposing a specific type of geometric constraints known as “periodic boundary conditions” on the unit cells, the boundary effects from the adjacent cells are taken into account. It is noteworthy that the boundary surfaces of the unit cell always appear in parallel pairs. The periodicity vectors along with the periodic boundary conditions are shown in Fig. 25.

On a pair of parallel opposite boundary surfaces, the displacements can be written as

in which the kth pair of two parallel opposite boundary surfaces of a repeated unit cell is identified by indices “\(k^+\)” and “\(k^-\)”. It is important to note that at the two parallel boundaries (periodicity) \(u_{i}^{*}\) is exactly the same; thus, the difference between \(u_{i}^{{k}^+}\) and \(u_{i}^{{k}^-}\) in the above two equations yields

with \({\tilde{\varepsilon }}_{ij}\) being the macroscopic (average) strains of the unit cell. For a specified macro-strain \({\tilde{\varepsilon }}_{ij}\), the right-hand side of (74) becomes constant owing to constant quantities \(\Delta x_{j}^{k}\) for each pair of the parallel boundary surfaces. Instead of giving Eq. (73) directly as boundary conditions, the constraint equations are imposed as nodal displacement constraint ones.

In order to estimate effective elastic properties with specific boundary conditions imposed on the microstructure, a strain energy-based method is exploited. The total strain energy stored in the unit cell is equal to the energy of an equivalent homogeneous continuum achieved through the prescribed strain/stress fields. In the elastic phase, the macroscopic behaviors of a unit cell can be represented by the effective strain tensor \(E_{ij}\) and stress tensor \(\sum _{ij}\) over the homogeneous equivalent model. The relation between \(\sum _{ij}\) and \(E_{ij}\) can then be written as:

where \(K^\mathrm{hom}\) is the effective (homogenized) stiffness matrix, \(\sum _{ij}=\frac{1}{V_{u}}\int _{V_{u}} \sigma _{ij}\hbox {d}V_{u}\) and \(E_{ij}=\frac{1}{V_{u}}\int _{V_{u}} {\varepsilon _{ij}\hbox {d}V_{u}}\) stand for the volume averaging of the microscopic stress and strain tensors, \(\sigma _{ij}\) and \(\varepsilon _{ij}\), respectively, and \(V_{u}\) refers to the volume of the unit cell.

In a 2D state, Eq. (75) can then be rewritten as follows:

The strain energy density over the unit cell \(U_\mathrm{cell}\) can be obtained from the following expression:

The components of the stiffness tensor for the unit cell can then be computed through the periodic boundary conditions imposed over a unit cell of domain \(\Omega \) with boundary \(\partial \Omega \). From there, the following six elementary tests are considered:

Load case 1: Prescribed unit strain state in the x-direction, \(E_{xx}=1,{E_{yy}=E}_{xy}=0\).

The corresponding displacement boundary conditions: \(u=x, v=0\), on \(\partial \Omega \), yielding:

Load case 2: Prescribed unit strain state in the y-direction, \(E_{xx}=E_{xy}=0,{E}_{yy}=1\).

The corresponding kinematic boundary conditions: \(u=0, v=y\), on \(\partial \Omega \), leading to:

Load case 3: Prescribed biaxial strain state, \(E_{xx}=E_{yy}=1,{E}_{xy}=0\).

The corresponding boundary conditions: \(u=x, v=y\), on \(\partial \Omega \), resulting in:

Load case 4: Prescribed shear strain state, \(E_{xx}=E_{yy}=0,{E}_{xy}=1\).

The corresponding kinematic boundary conditions: \(u=y/2, v=x/2\), on \(\partial \Omega \), from which we obtain:

Load case 5: Prescribed coupling strain state, \(E_{xx}=E_{xy}=1,{E}_{yy}=0\).

The kinematic boundary conditions in this case: \(u=x+y/2, v=x/2\), on \(\partial \Omega \), from which we get:

Load case 6: Prescribed coupling strain state, \(E_{xx}=0,{E}_{yy}=E_{xy}=1\).

The boundary conditions in this situation: write \(u=y/2, v=x/2+y\), on \(\partial \Omega \), allowing to achieve:

The components of the effective stiffness matrix, quantities \(K_{11}^\mathrm{hom},K_{22}^\mathrm{hom},K_{12}^\mathrm{hom},K_{66}^\mathrm{hom},K_{16}^\mathrm{hom},K_{26}^\mathrm{hom}\), as well as the equivalent moduli, coupling coefficients in the constitutive law, Eq. (72) and Poisson’s ratio are computed from the above numerical analyses.

Rights and permissions

About this article

Cite this article

Do, X.N., Reda, H. & Ganghoffer, J.F. Impact of damage on the effective properties of network materials and on bulk and surface wave propagation characteristics. Continuum Mech. Thermodyn. 33, 369–401 (2021). https://doi.org/10.1007/s00161-020-00908-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00161-020-00908-x