Abstract

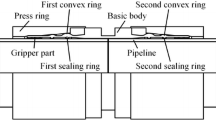

Perforated pipeline structure is widely utilized in the oil industry for its special functionality of communicating media with the ambient environment. A typical application is the slotted liner in SAGD (Steam Assisted Gravity Drainage) process, where the pipeline structure is manufactured with open slots to spread hot steam and collect the melted oil. Generally, a dense opening layout is employed to reduce flow resistance. On the other hand, inclusion of the many openings severely reduces the structural strength and stiffness, which causes the pipeline prone to deformation or even failure. Therefore, there exist the two conflicting requirements for design of the pipeline opening layout, and an interesting solution is proposed in this paper. To be specific, the pipeline structure is discretized into shell elements which are categorized into multiple types: without opening, with opening type 1, with opening type 2, etc. These element types are treated as different material phases, and design of the pipeline opening layout is transformed into a multi-material topology optimization problem. Multi-material level set method is employed to solve it, subject to the compliance minimization objective. In addition, a lower bound of opening quantity is applied by properly configuring the material fraction constraint, which ensures the low flow resistance. The effectiveness of the proposed method is proven through a few numerical case studies.

Similar content being viewed by others

References

Afonso SMB, Sienz J, Belblidia F (2005) Structural optimization strategies for simple and integrally stiffened plates and shells. Eng Comput 22:429–452

Allaire G, Jouve F, Toader AM (2004) Structural optimization using sensitivity analysis and a level-set method. J Comput Phys 194:363–393

Allaire G, Dapogny C, Delgado G, Michailidis G (2014) Multi-phase structural optimization via a level-set method. ESAIM: Control Optim Calc Var 20:576–611

Bendsoe MP, Sigmund O (1999) Material interpolation schemes in topology optimization. Arch Appl Mech 69:635–654

Bendsoe MP, Sigmund O (2003) Topology optimization – theory, methods and applications, Springer

Challis VJ, Guest JK (2009) Level set topology optimization of fluids in Stokes flow. Int J Numer Methods Eng 79:1284–1308

Deng YB, Zhang P, Liu YS, Wu YH, Liu ZY (2013a) Optimization of unsteady incompressible navier–stokes flows using variational level set method. Int J Numer Methods Eng 71:1475–1493

Deng YB, Liu ZY, Wu JF, Wu YH (2013b) Topology optimization of steady navier–stokes flow with body force. Comput Methods Appl Mech Eng 255:306–321

Furui K, Zhu D, Hill AD (2005) A comprehensive skin-factor model of horizontal-well completion performance. SPE Prod Facil 20:207–220

Furui K, Zhu D, Hill AD, Davis ER, Buck BR (2007) Optimization of horizontal well-completion design with cased/perforated or slotted liner completions. SPE Prod Oper 22:248–253

Gao T, Zhang WH (2011) A mass constraint formulation for structural topology optimization with multiphase materials. Int J Numer Methods Eng 88:774–796

Gibiansky LV, Sigmund O (2000) Multiphase composites with extremal bulk modulus. J Mech Phys Solids 48:461–498

Guo X, Zhang WS, Wang MY, Wei P (2011) Stress-related topology optimization via level set approach. Comput Methods Appl Mech Eng 200:3439–3452

Guo X, Zhang WS, Zhong WL (2014) Stress-related topology optimization of continuum structures involving multi-phase materials. Comput Methods Appl Mech Eng 268:632–655

Hvejsel CF, Lund E (2011) Material interpolation schemes for unified topology and multi-material optimization. Struct Multidiscip Optim 43:811–825

Lee SJ, Bae JE, Hinton E (2000) Shell topology optimization using the layered artificial material model. Int J Numer Methods Eng 47:843–867

Lund E (2009) Buckling topology optimization of laminated multi-material composite shell structures. Compos Struct 91:158–167

Lund E, Stegmann J (2005) On structural optimization of composite shell structures using a discrete constitutive parameterization. Wind Energy 8:109–124

Mei YL, Wang XM (2004) A level set method for structural topology optimization with multi-constraints and multi-materials. Acta Mech Sinica 20:507–518

Osher S, Sethian JA (1988) Front propagating with curvature-dependent speed: algorithms based on Hamilton–Jacobi formulations. J Comput Phys 79:12–49

Rozvany GIN (2009) A critical review of established methods of structural topology optimization. Struct Multidiscip Optim 37:217–237

Sigmund O (2001) Design of multiphysics actuators using topology optimization – part 2: two-material structures. Comput Methods Appl Mech Eng 190:6605–6627

Sigmund O, Maute K (2013) Topology optimization approaches. Struct Multidiscip Optim 48:1031–1055

Sigmund O, Torquato S (1997) Design of materials with extreme thermal expansion using a three-phase topology optimization method. J Mech Phys Solids 45:1037–1067

Stegmann J, Lund E (2005) Discrete material optimization of general composite shell structures. Int J Numer Methods Eng 62:2009–2027

van Dijk NP, Maute K, Langelaar M, van Keulen F (2013) Level-set methods for structural topology optimization: a review. Struct Multidiscip Optim 48:437–472

Vermaak N, Michailidis G, Parry G, Estevez R, Allaire G, Brechet Y (2014) Material interface effects on the topology optimization of multi-phase structures using a level set method. Struct Multidiscip Optim 50:623–644

Wang MY, Wang XM (2004) Color’ Level sets: a multi-phase method for structural topology optimization with multiple materials. Comput Methods Appl Mech Eng 193:469–496

Wang MY, Wang XM (2005) A level-set based variational method for design and optimization of heterogeneous objects. Comput Aided Des 37:321–337

Wang MY, Wang XM, Guo DM (2003) A level set method for structural topology optimization. Comput Methods Appl Mech Eng 192:227–246

Wang MY, Chen SK, Wang XM, Mei YL (2005) Design of multimaterial compliant mechanisms using level-set methods. J Mech Des 127:941–956

Wang YQ, Luo Z, Kang Z, Zhang N (2015) A multi-material level set-based topology and shape optimization method. Comput Methods Appl Mech Eng 283:1570–1586

Xia Q, Wang MY (2008) Simultaneous optimization of the material properties and the topology of functionally graded structures. Comput Aided Des 40:660–675

Xie YM, Steven GP (1993) A simple evolutionary procedure for structural optimization. Comput Struct 49:885–896

Zhang WS, Zhong WL, Guo X (2015) Explicit layout control in optimal design of structural systems with multiple embedding components. Comput Methods Appl Mech Eng 290:290–313

Zhuang CG, Xiong ZH, Ding H (2010) Topology optimization of multi-material for the heat conduction problem based on the level set method. Eng Optim 42:811–831

Zhou SW, Li Q (2008) A variational level set method for the topology optimization of steady-state Navier–Stokes flow. J Comput Phys 227:10178–10195

Acknowledgment

The authors would like to acknowledge the financial support: NSERC Discovery grants, MITACS accelerate cluster internship support, and China Scholarship Council (CSC) PhD student scholarship. All the research works were carried out at University of Alberta.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

To prove Eq. (26) equal to zero, we follow the derivations presented in (Guo et al. 2014). The derivation will be based on the 2D planar problem for the sake of simplicity, and it can be easily extended to shell problem by adding the design freedoms.

Through some mathematical manipulations (Guo et al. 2014), the following relationships can be derived:

in which, \( \tilde{\boldsymbol{p}} \) is the planar body force, and σ(ũ) is the second order Cauchy stress tensor. Accordingly, Eq. (37) can be derived as:

In Eq. (37), the first two terms at the right side could cancel each other at the material/material interface, and only remain at the fixed domain boundary ∂D. Therefore, Eq. (A2) can be further simplified into:

in which, \( \tilde{\boldsymbol{\tau}} \) is the planar boundary traction force and it is acted on the non-design boundary. According to Eq. (A1), Eq. (26) can be proven to hold.

The same process can be employed to prove the last four terms at the left side of Eq. (28) equal to zero, as demonstrated in Eq. (A2).

Equation (A2) holds according to Eq. (A1), \( \tilde{\boldsymbol{w}}=-\tilde{\boldsymbol{u}} \), and \( \tilde{\boldsymbol{p}}\left(\boldsymbol{w}\right)=-\tilde{\boldsymbol{p}} \), in which \( \tilde{\boldsymbol{p}}\left(\tilde{\boldsymbol{w}}\right) \) is the planar body force caused by \( \tilde{\boldsymbol{w}} \).

Rights and permissions

About this article

Cite this article

Liu, J., Ma, Y. Design of pipeline opening layout through level set topology optimization. Struct Multidisc Optim 55, 1613–1628 (2017). https://doi.org/10.1007/s00158-016-1602-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-016-1602-3