Abstract

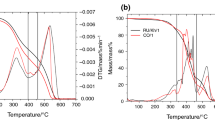

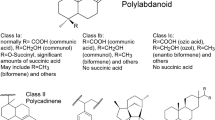

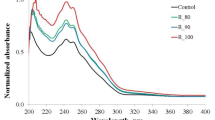

The resins developed with Fillaeopsis discophora tannin extract using either Vitellaria paradoxa trunk exudate as bio hardener or glyoxal as hardener were thermally analyzed using thermomechanical (TMA) and thermogravimetric (TGA) analysis. A microscopic interpretation of glass transition, physical aging, and phase segregation was analyzed and the relative activation energy was determined. The activation energies of gelling of the resins above are 57,658 and 52,967 J. mol−1, respectively. Their glass transition temperatures are 172 °C and 149 °C respectively. The tannin extract used in the development of these two resins is of a condensed polyflavonoid type linked to some furan residues. The resin developed with the Vitellaria paradoxa exudate as a bio-hardener has a good thermal behavior and it degrades slower than that with glyoxal as hardener.

Similar content being viewed by others

References

Anderson BJ (2013) Thermal stability and lifetime estimates of a high temperature epoxy by Tg reduction. Polym Degrad Stab 98(11):2375–2382. https://doi.org/10.1016/j.polymdegradstab.2013.08.001

BS EN 319 (1993) Particleboard and fibreboard - Determination of the tensile strength perpendicular to the panel faces. ISBN : 0 580 21134, 12

Da Costa EM, Jose´ MBF, Ticiano GN, Rui OM (2002) Thermal characterization of the quercetin and rutin flavonoids. Thermochimica Acta. Thermochimica Acta 392–393:79–84

Hasselman DP, Johnson LF (1987) Effective thermal conductivity of composites with interfacial thermal barrier resistance. J Compos Mater 21(6):508–515

Jun Z, Hai L, Pizzi A, Guanben D, Shuduan D (2015) Preparation and characterization of grinding wheels based on a bioresin matrix and glass sand abrasives. Bio Resources 10(3):5369–5380

Konai N, Pizzi A, Raidandi D, Lagel MC, L’Hostis C, Saidou C, Hamido A, Abdalla S, Bahabri F, Ganash A (2015) Aningre tannin extract characterization and performance as an adhesive resin. Ind Crops Prod 77:225–231

Konai N, Danwe R, Pizzi A, Girods P, Lagel M-C, Kple M (2016) Thermogravimetric analysis of anningre tannin resin. Maderas-Cienc Tecnol 18(2):2016. https://doi.org/10.4067/S0718-221X2016005000022

Mansouri H, Navarrete R, Pizzi A, Tapin-Lingua A, Benjelloun-Mlajah S, Pasch B, Rode H, Delmotte K, Rigolet L (2011) Synthetic resin free wood panel adhesives from mixed low molecular mass lignin and tannin. Eur J Wood Prod 69:221–229

Ndiwe B, Ai P, Tibi B, Danwe R, Konai N, Amirou S (2019) African tree bark exudate extracts as biohardeners of fully biosourced thermoset tannin adhesives for wood panels. Ind Crops Prod 132:253–268. https://doi.org/10.1016/j.indcrop.2019.02.023

Petrovich ZS, Zavargo Z, Flynn JH, Macknight WJ (1994) Thermal degradation of segmented polyurethanes. J Appl Polym Sci 51(1):1087–1095

Pichelin FM, Nakatani M, Pizzi A, Wieland S, Despres A, Rigolet S (2006) Thick wood panels bonded industrially with formaldehyde free tannin adhesives. For Prod J 56:31–36

Rimdusit S, Ishida H (2000) Development of new class of electronic packaging materials based on ternary systems of benzoxazine, epoxy and phenolic resins. Polymer 41(22):7941–7949. https://doi.org/10.1016/S0032-3861(00)00164-6

Scatolino MV, Protásio TDP, Mendes RF, Mendes LM (2015) Thermal stability of Pinus oocarpa and maize cob particleboards. Cienc Agrotecnol 39(4):348–354. https://doi.org/10.1590/S1413-70542015000400005

Sealy–Fisher VJ, Pizzi A (1992) Increased pine tannins extraction and wood adhesives development by phlobaphenes minimization. Holz Roh-Werkst 50:212–220

Serror M, Colin X, Larché JF (2013) Thermal aging of a carbon composite rod/epoxy. Analysis of the damage and its consequences on the mechanical properties. Rev Compos Matér Avancés 23:51–67

Zhang W, Yang X, Li C, Liang M, Luand C, Deng Y (2011) Mechanochemical activation of cellulose and its thermoplastic polyvinyl activation of cellulose and its thermoplastic polyvinyl alcohol eco composites with enhanced physicochemical properties. Carbohyd Polym 83(1):257–263

Zhang J, Luo H, Pizzi A, Guanben D, Deng S (2015) Preparation and Characterization of Grinding Wheels Based on a Bioresin Matrix and Glass Sand Abrasives. Bioresources.com 10(3):5369–5380

Acknowledgements

The authors thank the LERMAB's authorities of the ENSTIB for giving the opportunities to do various tests. The authors did not receive support from any organization for the submitted work. They certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Konai, N., Karga Tapsia, L., Pizzi, A. et al. Thermal analysis and aging monitoring of biosourced resins. Eur. J. Wood Prod. 80, 1433–1440 (2022). https://doi.org/10.1007/s00107-022-01868-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-022-01868-6