Abstract

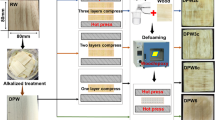

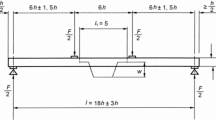

Low quality beech (Fagus sylvatica L.) and Norway spruce (Picea abies (L.) Karst.) were densified with viscoelastic thermal compression (VTC) process to two different degrees of densification, and lamellas were used to manufacture different types of 3-layer VTC composites. Bending properties of 3-layer VTC composites bonded with phenol formaldehyde (PF) adhesive and liquefied wood (LW) were determined and compared to 3-layer composites produced with undensified beech or spruce wood lamellas. Morphology of VTC spruce wood of higher density was analysed with fluorescent microscopic technique. All composites produced with densified beech lamellas and bonded with PF adhesive had significantly higher values of modulus of rupture (MOR) and modulus of elasticity (MOE) than composites produced with undensified lamellas. Densified spruce lamellas contributed to better bending performance of 3-layer VTC composites bonded with PF adhesive to some extent. Furthermore, composites bonded with LW had significantly lower MOR and MOE values compared to composites bonded with PF adhesive. Study of VTC spruce wood microstructure showed that densification caused non-uniform deformation of cell wall structure, in which cell wall fractures were observed.

Zusammenfassung

Buchen- (Fagus sylvatica L.) und Fichtenholz- (Picea abies (L.) Karst.) Lamellen geringer Qualität wurden mittels viskoelastischer thermischer Verdichtung (VTC) in zwei Verdichtungsgraden verdichtet und zur Herstellung unterschiedlicher dreilagiger VTC-Verbundwerkstoffe verwendet. Die Biegeeigenschaften der dreilagigen, mit Phenol-Formaldehydharz (PF) und Flüssigholz (LW) verklebten VTC-Verbundwerkstoffe wurden mit den Eigenschaften von dreilagigen Verbundwerkstoffen aus unverdichteten Buchen- oder Fichtenholz-Lamellen verglichen. Die Morphologie von VTC-Fichtenholz höherer Dichte wurde mittels Fluoreszenzmikroskopverfahren untersucht. Die Biegefestigkeit (MOR) und der Elastizitätsmodul (MOE) aller aus verdichtetem Buchenholz hergestellter und mit PF-Klebstoff verklebter Verbundwerkstoffe waren signifikant höher als bei den Verbundwerkstoffen aus unverdichteten Lamellen. Die verdichteten Fichtenlamellen trugen in einem gewissen Maße zu einem besseren Biegeverhalten der dreilagigen, mit PF-Klebstoff verklebten VTC-Verbundwerkstoffe bei. Daneben wiesen die mit Flüssigholz verklebten Verbundwerkstoffe signifikant niedrigere Biegefestigkeits- und Elastizitätsmodulwerte auf als die mit PF verklebten Verbundwerkstoffe. Eine Untersuchung der Mikrostruktur von VTC Fichtenholz zeigte, dass die Verdichtung zu einer unregelmäßigen Verformung der Zellwandstruktur führte, bei der Schädigungen der Zellwand auftraten.

Similar content being viewed by others

References

Daniel IM, Abot JL, Schubel PM, Luo JJ (2012) Response and damage tolerance of composite sandwich structures under low velocity impact. Exp Mech 52(1):37–47

Jennings JD, Zink-Sharp A, Kamke FA, Frazier CE (2005) Properties of compression densified wood. Part 1: bond performance. J Adhes Sci Technol 19(13–14):1249–1261

Kamke F (2006) Densified radiata pine for structural composites. Maderas Ciencia y tecnología 8(2):83–92

Kamke FA, Sizemore H (2008) Viscoelastic thermal compression of wood. US Patent Application No. 7.404.422

Kawasaki T, Kawai S (2006) Thermal insulation properties of wood-based sandwich panel for use as structural insulated walls and floors. J Wood Sci 52(1):75–83

Kawasaki T, Hwang K, Komatsu K, Kawai S (2003) In-plane shear properties of the wood-based sandwich panel as a small shear wall evaluated by the shear test method using tie-rods. J Wood Sci 49(3):199–209

Kobayashi M, Asano T, Kajiyama M, Tomita B (2004) Analysis on residue formation during wood liquefaction with polyhydric alcohol. J Wood Sci 50(5):407–414

Kutnar A, Kamke F, Sernek M (2008a) The mechanical properties of densified VTC wood relevant for structural composites. Holz Roh- Werkst 66(6):439–446

Kutnar A, Kamke FA, Petric M, Sernek M (2008b) The influence of viscoelastic thermal compression on the chemistry and surface energetics of wood. Colloid Surf A-Physicochem Eng Asp 329(1–2):82–86

Kutnar A, Kamke FA, Nairn JA, Sernek M (2008c) Mode II fracture behavior of bonded viscoelastic thermal compressed wood. Wood Fiber Sci 40(3):362–373

Kutnar A, Kamke FA, Sernek M (2009) Density profile and morphology of viscoelastic thermal compressed wood. Wood Sci Technol 43(1–2):57–68

Pan H (2011) Synthesis of polymers from organic solvent liquefied biomass: a review. Renew Sust Energ Rev 15(7):3454–3463

Pan H, Shupe TF, Hse CY (2007) Characterization of liquefied wood residues from different liquefaction conditions. J Appl Polym Sci 105(6):3740–3746

Stapleton SE, Adams DO (2008) Crush initiators for increased energy absorption in composite sandwich structures. J Sandw Struct Mater 10(4):331–354

Ugovšek A, Sernek M (2013) Effect of pressing parameters on the shear strength of beech specimens bonded with low solvent liquefied wood. J Adhes Sci Technol 27(2):182–195

Ugovšek A, Budija F, Kariz M, Sernek M (2011) The influence of solvent content in liquefied wood and of the addition of condensed tannin on bonding quality. Drv Ind 62(2):87–95

Ugovšek A, Kamke FA, Sernek M, Pavlič M, Kutnar A (2012a) The wettability and bonding performance of densified VTC beech (Fagus sylvatica L.) and Norway spruce (Picea abies (L.) Karst.), bonded with phenol-formaldehyde adhesive and liquefied wood. Eur J Wood Prod 71(3):371–379

Ugovšek A, Sever Škapin A, Humar M, Sernek M (2012b) Microscopic analysis of the wood bond line using liquefied wood as adhesive. J Adhes Sci Technol. doi:10.1080/01694243.2012.736854

Zhang HR, Pang H, Shi JZ, Fu TZ, Liao B (2012) Investigation of liquefied wood residues based on cellulose, hemicellulose, and lignin. J Appl Polym Sci 123(2):850–856

Acknowledgments

The authors gratefully acknowledge the financial support by the Slovenian Research Agency through the fundamental research project J4-2177 “Development of environmentally friendly adhesives from renewable plant polymers” and bilateral project BI-US/11-12-041 “Adhesive bonding of viscoelastic thermal compressed wood with environmentally friendly adhesives”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ugovšek, A., Kamke, F.A., Sernek, M. et al. Bending performance of 3-layer beech (Fagus sylvativa L.) and Norway spruce (Picea abies (L.) Karst.) VTC composites bonded with phenol–formaldehyde adhesive and liquefied wood. Eur. J. Wood Prod. 71, 507–514 (2013). https://doi.org/10.1007/s00107-013-0704-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-013-0704-5