Abstract

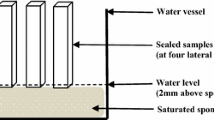

The objectives of this study are to quantitatively evaluate, using a wetting model, the wettability of three probe liquids with different properties on heat-treated jack pine surfaces prepared by three different types of machining (sanding, planing and sawing) and to compare with those of untreated wood surfaces. The results indicate that the heat-treated wood is wetted less than the untreated wood due to degradation of wood components (hemicelluloses, lignin and cellulose) during heat treatment and it absorbs less liquid. The heat-treated wood becomes most hydrophobic when wood surfaces are sanded by 180-grit paper compared to those prepared by other machining process. Heat-treated wood surfaces are strongly acidic similar to those of untreated wood. Consequently, the basic probe liquid, formamide, shows the highest spreading and penetration rate (K-value) on wood surfaces.

Zusammenfassung

Ziel dieser Studie war es, die Benetzbarkeit mit drei Versuchsflüssigkeiten mit unterschiedlichen Eigenschaften von thermisch behandeltem Jack Pine Holz, dessen Oberflächen unterschiedlich bearbeitet worden waren (schleifen, hobeln, sägen) quantitativ anhand eines Modells zu bestimmen und mit unbehandelten Holzoberflächen zu vergleichen. Die Ergebnisse zeigen, dass thermisch behandeltes Holz aufgrund des Abbaus von Holzbestandteilen (Hemicellulose, Lignin und Cellulose) bei der thermischen Behandlung weniger stark benetzt wurde als unbehandeltes Holz und dass es weniger Flüssigkeit aufnimmt. Thermisch behandeltes Holz, dessen Oberfläche mit Schleifpapier der Körnung 180 bearbeitet wurde, ist im Vergleich zu anders bearbeitetem Holz am hydrophobsten. Thermisch behandelte Holzoberflächen sind stark acidisch, ähnlich wie unbehandeltes Holz. Folglich weist die basische Testflüssigkeit Formamid die höchste Ausbreitungs- und Eindringrate (K-Wert) auf Holzoberflächen auf.

Similar content being viewed by others

References

de Moura LF, Hernandez RE (2006) Effects of abrasive mineral, grit size and feed speed on the quality of sanded surfaces of sugar maple wood. Wood Sci Technol 40(6):517–530

Gindl M, Sinn G, Rieterer A, Tschegg S (2001) Wood surface energy and time dependence of wettability: a comparison of different wood surfaces using an acid-base approach. Holzforschung 55(4):433–440

Hakkou M, Petrissans M, Zoulalian A, Gerardin P (2005) Investigation of wood wettability changes during heat treatment on the basis of chemical analysis. Polym Degrad Stab 89(1):1–5

Kocaefe D, Poncsak S, Dore G, Younsi R (2008) Effect of heat treatment on the wettability of white ash and soft maple by water. Holz Roh- Werkst 66(5):355–361

Kocaefe D, Younsi R, Chaudry B, Kocaefe Y (2006) Modeling of heat and mass transfer during high temperature treatment of aspen. Wood Sci Technol 40(5):371–391

Liptakova E, Kudela J (1994) Analysis of the wood-wetting process. Holzforschung 48(2):139–144

Liptakova E, Kudela J, Bastl Z, Spirovova I (1995) Influence of mechanical surface-treatment of wood on the wetting process. Holzforschung 49(4):369–375

Liu ZM, Wang FH, Wang XM (2004) Surface structure and dynamic adhesive wettability of wheat straw. Wood Fiber Sci 36(2):239–249

Lu JZ, Wu QL (2006) Surface characterization of chemically modified wood: dynamic wettability. Wood Fiber Sci 38(3):497–511

Mantanis GI, Young RA (1997) Wetting of wood. Wood Sci Technol 31(5):339–353

Petrissans M, Gerardin P, El Bakali I, Serraj M (2003) Wettability of heat-treated wood. Holzforschung 57(3):301–307

Richter K, Feist WC, Knaebe MT (1995) The effect of surface-roughness on the performance of finishes. 1. Roughness characterization and stain performance. For Prod J 45(7–8):91–97

Rowell R, Lange S, Davis M (2000) Steam stabilization of aspen fiberboards. Proc of Fifth Pacific Rim Bio-based Composites Symp: 425–438

Scheikl M, Dunky M (1998) Measurement of dynamic and static contact angles on wood for the determination of its surface tension and the penetration of liquids into the wood surface. Holzforschung 52(1):89–94

Shi SQ, Gardner DJ (2001) Dynamic adhesive wettability of wood. Wood Fiber Sci 33(1):58–68

Sinn G, Gindl M, Reiterer A, Stanzl-Tschegg S (2004) Changes in the surface properties of wood due to sanding. Holzforschung 58(3):246–251

Stehr M, Gardner DJ, Walinder MEP (2001) Dynamic wettability of different machined wood surfaces. J Adhes 76(3):185–200

Wang G, Yu YL, Yu WJ (2007) Effects of temperature on the dynamic adhesive wettability of PF resin on bamboo surface. Beijing Linye Daxue Xuebao/Journal of Beijing Forestry University 29(3):149–153

Acknowledgements

The financial support of FQRNT, UQAC, FUQAC, Développement Économique Canada (DEC), Ministère du Développement Économique, de l’Innovation et de l’Exportation (MDEIE), Conférence Régionale des Élus du Saguenay-Lac-St-Jean (CRÉ) and the contributions of Alberta Research Council, Cégep de Saint-Félicien, FP Innovations, PCI Ind., Ohlin Thermotech, Kisis Technology, and Industries ISA are greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, X., Kocaefe, D., Boluk, Y. et al. Effect of surface preparation on the wettability of heat-treated jack pine wood surface by different liquids. Eur. J. Wood Prod. 70, 711–717 (2012). https://doi.org/10.1007/s00107-012-0605-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-012-0605-z