Abstract

The purpose of this study is to examine the mechanical properties of ACQ-treated glulam made from three hardwood lumbers. Two nondestructive methods, ultrasonic wave and tap tone method, were also used in this study. The results showed that the dynamic MOE and static MOE of lumbers decreased with increased ACQ preservative retention. ANOVA showed no significant difference in the MOE values of glulam between untreated and ACQ-treated group. However, it was also found that glulam made from red oak lumbers had the highest bending strength retention ratio. The shear strength of the glulam also showed similar results. Finally, no delaminating was found in all glulams after the specimens under soaked and boiled delamination tests.

Zusammenfassung

In dieser Studie werden die mechanischen Eigenschaften von mit ACQ behandeltem Brettschichtholz aus drei verschiedenen Laubholzarten untersucht. Dabei wurden auch zwei zerstörungsfreie Methoden, nämlich Ultraschall- und Längsschwingungsmessung, verwendet. Die Ergebnisse zeigten, dass der dynamische und der statische Elastizitätsmodul (MOE) von Schnittholz mit zunehmender ACQ-Schutzmittelaufnahme abnahmen. Die ANOVA-Analyse ergab keine signifikanten Unterschiede zwischen den MOE Werten der unbehandelten und der behandelten Prüfkörpergruppe. Daneben hat sich gezeigt, dass die Biegefestigkeit bei Brettschichtholz aus Roteiche am geringsten beeinträchtigt war. Die Scherfestigkeit von Brettschichtholz zeigte ähnliche Ergebnisse. Delaminierungsprüfungen ergaben bei allen untersuchten Brettschichtholzgruppen keine Delaminierungen.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Glued laminated timber, known as glulam, is an engineered wood product which can be produced from all kinds of wood species. It can also be constructed from small-diameter timber meaning that dependence on old growth trees, considered necessary to provide the high strength and large span for architectural design, is a thing of the past (Yang et al. 2008). Glulam products have been successfully applied to construction as building materials in North America and Europe for some time. However, wood is still a kind of biological material; if untreated, it becomes subject to degradation in the end use stage, such as decay, fungus damage, and insect infestation. These environmental and biological damages reduce the lifetime of wood products. Consequently, wood preservatives are widely used to extend their lifetime.

A typical waterborne preservative is chromated copper arsenate (CCA) combining copper, chromium, and arsenic to have high resistance to leaching and very good performance in service. However, the Environmental Protection Agency (EPA) of the United States does not allow for CCA treated wood to be used in most residential applications anymore as of 1 January 2004. In Europe, Germany was the first country to ban CCA treated wood in the mid 1970s, followed by Sweden in 1993. Recent documents (EIGA 2008) show that CCA compounds have been regulated by arsenic compounds in the Commission Directive 2003/2/EC of 6 January 2003 relating to restrictions on the marketing and use of arsenic in the 10th adaptation to technical progress of the Council Directive 76/769/EEC, and it was applicable as of 30 June 2004. Nevertheless, Bergman and Jermer (2010) presented results of a 30 year field trial case study of glued laminated poles made of CCA impregnated wood.

Therefore, two waterborne preservatives have been primarily promoted by the industry and have substituted the withdrawal of CCA. Both copper azole (CBA-A and CA-B) and ammoniacal copper quaternary compound (ACQ) are now widely used across the United States and North America (Goodell et al. 2007; Gaspar et al. 2010).

ACQ has been successfully replaced by preservatives based on micronized copper (Evans et al. 2008); MCQ (micronized copper quat) covers more than 75% of the market of copper based preservatives for residential applications in the US (Preston et al. 2008). Yildiz et al. (2004) evaluated the effects of CCA, ACQ, Tanalith E, and Wolmanit CX-8 preservatives on the mechanical properties of Scots Pine (Pinus sylvestris). The results showed that these chemicals increased, decreased or did not affect the modulus of elasticity and modulus of rupture of wood. Similar results were also reported by Barnes and Lindsey (2009). Jiang et al. (2007) evaluated the influence of ACQ treatments on the mechanical properties of blue-stained lodgepole pine (Pinus contorta). The results showed that the MOR (modulus of rupture), MOE (modulus of elasticity), and the shear strength parallel to the grain were found to not significantly differ between treated wood and non-treated wood, and there were no statistically significant differences among the three concentrations (2.8%, 2.0%, and 1.2%) of ACQ. In the above, most researches focused on the bending and bonding performance of treated softwood, however, the effects on treated hardwood or hardwood products are not clear. Therefore, the purpose of this study was to determine the effects of ACQ preservatives on the mechanical and bonding properties of glulam made from three hardwood lumbers. It was also a basic study and requirement for developing a traffic guard rail made from glulam in Taiwan.

2 Material and methods

2.1 Materials

In this study, the heartwood of three hardwoods, beech (Fagus spp.), hard maple (Acer spp.), and red oak (Quercus rubra) was used. The specimens were from heartwood and average air-dried densities were 703 kg/m3, 742 kg/m3, and 785 kg/m3, respectively. Specimens were cut into 30 mm×60 mm cross sections and 1,800 mm in length. 120 pieces of specimens were prepared for each species. The moisture content was conditioned at 15% prior to treatment.

2.2 Preservative treatment

ACQ preservative solution (2%) was prepared and the full-cell method was used to ensure preservative retention of specimens above 1.3 kg/m3 (K2 grade), 2.6 kg/m3 (K3 grade), and 5.2 kg/m3 (K4 grade) according to the Chinese National Standard 3000 (2001). First, the wood specimens were placed into an impregnation vessel and preliminary vacuum was applied at 0.08 MPa for 20 min, which removed some air from the wood to increase uptake and penetration of preservatives into the wood. Then, a preservative solution was poured into the vessel from a storage tank and pressure was applied up to 0.98 MPa for 40 min. Finally, a vacuum was applied at 0.08 MPa for 20 min. to remove excess preservatives from the surface of the wood following the treatment. The retention of wood preservatives was calculated as follows:

where R is the retention of wood preservatives (kg/m3), m 1 is the mass of the lot of wood specimens before impregnation treatment (kg), m 2 is the mass of the lot of wood specimens after impregnation treatment (kg), C is the concentration (%) of preservation solution, and V is the volume of the lot of wood specimens before impregnation treatment (m3).

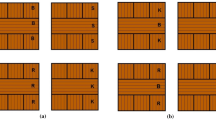

2.3 Manufacture of glulam

To enhance the superior mechanical performance of glulam, high-MOE laminae were arranged at the top and the bottom positions. The glulam was made of three pieces of lumber and its dimensions were 90 mm in thickness, 60 mm in width, and 1800 mm in length. Resorcinal resin adhesive (RF) was applied with a spreading ratio of 0.250 kg/m2. The solid content, pH value, density, and gelation time were 60.1%, 8.0, 1.15 g/cm3, and 25 min, respectively. The laminae were pressed together at 0.98 MPa when the glulam was manufactured.

2.4 Nondestructive test

Ultrasonic wave and tap tone methods were used to evaluate the modulus of elasticity of the specimens (lamina). After laminas had been made into laminate, tap tone method was carried out again to evaluate the dynamic modulus of elasticity of the entire glulam.

Sylvatest (CBS&CBT) uses the ultrasonic wave method to estimate the dynamic modulus of elasticity (DMOE u ) of the lumber at a frequency of 16 kHz. The ultrasonic wave velocity (V u ) and DMOE u were calculated as follows:

and

where V u is the ultrasonic wave velocity parallel to the grain of the lumber, L is the distance between the two transducers, t is the propagation time of the pulse from the transmitting transducer to the receiving one, DMOE u is the dynamic modulus of elasticity parallel to the grain of the lumber, and ρ is the density of the lumber.

Tap tone sound velocity (V f ) was calculated from the natural frequency (f r ), which was obtained from the FFT analyzer. The tap tone sound velocity (V f ) and dynamic modulus of elasticity (DMOE f ) were calculated as follows:

and

where L and ρ were similar to the notations of the ultrasonic wave method.

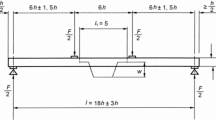

2.5 Bending test

The bending test was carried out on a Shimadzu UH-10A universal testing machine by three-point loading method. The loading stress rate was kept at 14.7 MPa per minute. Specimen span was 1650 mm. The MOE and MOR could be expressed as follows:

and

where ΔP is the difference between the upper and lower loading limits in the proportional limit region (N), Δy is the deflection with respect to ΔP (mm), L is span (mm), b is the width of the glulam (mm), h is the thickness of the glulam (mm), and P is the maximum loading (N).

2.6 Block-type glue-line shear test

The shear test parallel to the grain was measured. The average loading speed was about 9800 N/min. The load at the specimen rupture was between 15% and 85% of the capacity of the test machine. The shear strength was calculated as follows:

where P(N) is the rupture load, and A (mm2) is the area of bonding layer.

2.7 Soaking and boiling delamination test

The soaking and boiling delamination test specimen was cut from both ends of each sample glulam, with the original cross section (90 mm×60 mm) and at a length of 75 mm. For the soaking delamination test, the specimen was immersed in water at a room temperature of 25°C for 24 hours and then placed in the oven at 70°C to dry for 24 hours.

For the boiling delamination test, the specimen was immersed in boiling water for 4 hours, and then immersed in water at a room temperature of 25°C for 1 hour. After that, the specimens were placed in the oven at 70°C to dry for 24 hours. Both procedures were repeated twice and the delaminating ratio was calculated by the following formula:

3 Results and discussion

3.1 Physical and mechanical properties of lumber

The physical and mechanical characteristics of the lumbers used in this study are summarized in Table 1. The MOE values for beech sawn lumber ranged from 7.1 to 14.7 GPa, and the average MOE value was 11.1 GPa. It was also found that the values of DMOE u and DMOE f were 35.1% and 22.5% higher than the MOE values, respectively. Similar results were also found in hard maple and red oak sawn lumbers. The MOE values for hard maple sawn lumber ranged from 7.1 to 16.7 GPa, and the average MOE value was 13.5 GPa. The analysis showed that the values of DMOE u and DMOE f were 37.8% and 24.4% higher than the MOE values, respectively. The MOE values for red oak sawn lumber ranged from 5.7 to 17.7 GPa, and the average MOE value was 12.7 GPa. The analysis showed that the values of DMOE u and DMOE f were 41.7% and 29.9% higher than the MOE values, respectively.

3.2 Effects of ACQ preservatives on the MOE properties of sawn lumbers

Table 2 indicates that the MOE of all specimens decreased after ACQ preservatives treatment, however, the MOE retention ratio of ACQ-treatment ranged from 83.9% to 90.2% for beech specimens, from 91.5% to 93.6% for hard maple specimens, and from 90.4% to 95.6% for red oak specimens, respectively. Both the DMOE u by the ultrasonic wave method and the DMOE f by the tap tone method showed similar results.

To determine the effects of ACQ preservatives on the MOE of lumbers, a one-way ANOVA (ANalysis Of VAriance) test was performed and homogenous groups were determined. With regard to the MOE values, there were no significant differences between the untreated and ACQ-treated group for the hard maple and red oak specimens. However, there was a significant difference between the untreated and the K3, K4 group, while there were no significant differences in the ACQ-treated group for beech specimens. Similar results were reported by Yildiz et al. (2004) regarding the effects of wood preservatives on the mechanical properties of Scots pine (Pinus sylvestris). It was pointed out by Yildiz et al. (2004) that there are no significant differences in MOE between being treated or not by ACQ or CCA preservatives.

It is believed that this is predominantly due to the depolymerisation of wood caused by excess of ethanolamine. Humar et al. (2007) reported that it was limited for the amount of the functional group in wood which can react with the copper/ethanolamine complex, in addition during reaction of ethanolamine with wood or its components, free radicals were formed which will cause depolymerisation of lignin (Humar et al. 2003). Further research also indicated that ethanolamine in copper based wood preservatives in the first place enables copper fixation. Besides, it causes degradation of lignin or other wood components which can change the mechanical properties (Humar et al. 2008).

3.3 Effects of ACQ preservatives on the bending properties of glulam

The laminate configuration and modulus of elasticity of glulam reported in previous research (Yang et al. 2007) was used in this study.

The effect of ACQ preservatives on the bending properties of glulam is shown in Table 3. In that table, “Retention ratio” means the percentage of mechanical property of treated wood to that of untreated wood. The average MOE values of beech glulam were 12.5 GPa for the untreated group, and 10.2 to 10.9 GPa for the ACQ-treated group. The MOE retention ratios of beech glulam ranged from 81.6% to 87.2%. It was found that the MOE values decreased as ACQ preservative retention increased. Hard maple and red oak glulam showed a higher MOE retention ratio than that of beech glulam. For hard maple glulam, the average MOE value for the untreated group was 14.2 GPa, however, the average MOE values for the ACQ-treated group ranged from 13.4 to 13.8 GPa. The MOE retention ratios ranged from 94.4% to 97.2% for the ACQ-treated glulam. Similar results were also shown in red oak glulam, where the average MOE value for the ACQ-treated glulam ranged from 12.9 to 13.3 GPa. This was slightly lower than that of the untreated group. The MOE retention ratios ranged from 94.2% to 97.1% for the ACQ-treated glulam. Further, it was also found that there was no significant difference between the untreated and the ACQ-treated groups for each glulam specimen according to the ANOVA test.

Compared to the MOE retention ratio, the MOR retention ratios of glulam were lower. Table 3 shows that the MOR retention ratios range from 72.4% to 85.5% for beech glulam, 66.5% to 79.3% for hard maple glulam, and 85.8% to 99.1% for red oak glulam, respectively.

Following the ANOVA test on the MOR values, there was no significant difference among the untreated and ACQ-treated group for red oak glulam. However, a significant difference was found between the untreated and K4 group, while there was no significant difference between the untreated and the K2, K3 group for beech glulam. In addition, for hard maple glulam, there was a significant difference between the untreated and the K3, K4 group, while there were no significant differences between the untreated and the K2, K3 group. To summarize the bending performance of these three species, it was found that red oak glulam had the highest bending strength retention ratio. Previous work investigating the mechanical properties of preservative treated wood showed that ACQ treated wood did not cause significant reductions in its bending properties (Barnes and Winandy 1986; Barnes et al. 1993). Similar results also showed that MOE was not affected by many waterborne preservative treatments (Gaspar et al. 2010; Barnes et al. 1993; Resch and Parker 1982; Bendtsen et al. 1983; Mitchell and Barnes 1986; Winandy 1989).

Compared with the values of MOE, the MOR values often decreased from 0% to 20%, depending on the retention and severity of the redrying temperature employed (Winandy 1995). Barnes and Lindsey (2009) also reported that the MOR values of ACQ-treated southern pine dimension stock were 85% to 91% of those the control group according to the AWPA standardized system. Waterborne preservative treatments generally reduced the mechanical properties of the wood. The strength loss caused by a waterborne preservative directly relates to its chemistry and the severity of its fixation/precipitation reaction. Winandy (1995) contended that these effects on the mechanical properties appear to be directly related to several key wood material factors and pretreatment, treatment, and post-treatment processing factors.

Compared to acidic chromium-containing waterborne preservative formulations (pH value is 1.6 to 2.5) which react with the wood cell wall components by undergoing hydrolytic reduction upon contact with wood sugars, ammoniacal waterborne preservative formulations (pH11) do not react with the cellulose or the hexose hemicelluloses in the wall. However the ammonia can solubilize and/or react with the lignin and the pentose hemicelluloses (Ostmeyer et al. 1988, 1989). In addition, heat and ammonia can cause the wood to swell, thereby increasing preservative penetration. Therefore, the preservative was often heated when treating difficult-to-treat species. Lebow (1992) indicated that some metallic components of ammoniacal formulations precipitate to water-insoluble complexes on or in the cell wall as some ammonia co-solvent evaporates, while the rest of the nitrogen complexes with metal as it undergoes ion-exchange reactions with the lignin and/or hemicelluloses. The rate of this completion and the permanence of the ammoniacal preservatives can be significantly altered by the lipophilicity of the ammonia as it influences adsorption (Loubinoux et al. 1992). Barnes (1985) showed that adding heat during and after treatment, potentially accelerates these hydrolytic reactions, magnifying strength reduction. The sensitivity to strength loss on exposure to heat of waterborne preservative formulations is also enlarged by the high moisture content induced by the water solvent in the systems.

3.4 Effects of ACQ preservatives on the bonding properties of glulam

To understand the effect of adhesive bonds on ACQ-treated glulam, shear strength and delamination tests were carried out.

The glue-line shear strength of glulam after ACQ preservatives treatment is shown in Table 4. The fiber failure percentage of all specimens was reached by 100%. The results suggested that the shear strength, similar to the bending properties of glulam, decreased as the ACQ preservatives retention increased. The shear strength retention ratios ranged from 73.9% to 85.4% for beech glulam, from 71.6% to 84.6% for hard maple glulam, and from 80.8% to 95.2% for red oak glulam. The results also showed that the shear strength retention ratios of red oak glulam were higher than those of beech and hard maple glulam.

Using the ANOVA test, it was also shown that there was a significant difference between the untreated group and the ACQ preservatives treated group. However, there was no significant difference between the untreated and the K2 group for red oak glulam, while there was a significant difference between the untreated and the K3, K4 group. Further, after the soaking and the boiling delaminating test, it was found that there was no delaminating in all glulam specimens.

4 Conclusion

The effect of ACQ preservatives on the mechanical properties of glulam made from beech, hard maple, and red oak were examined in this study. The results indicated that the MOE values of lumber decreased after ACQ preservatives treatment. The MOE values of glulam showed similar results to those of lumbers. They decreased as ACQ preservative retention increased, however, there was no significant difference between the untreated and ACQ-treated group. Although no delaminating was found in all glulam specimens, the shear strength of glulam was affected by the ACQ treatment. Red oak glulam had the highest bending strength retention ratio and shear strength retention ratio.

References

Barnes HM (1985) Effect of steaming temperature and CCA retention on mechanical properties of Southern Pine. For Prod J 35(6):31–32

Barnes HM, Winandy JE (1986) Effects of seasoning and preservatives on the properties of treated wood. In: Proceedings of the American wood-preservers’ association, vol 82, pp 95–105

Barnes HM, Lyon DE, Zahora A, Muisu F (1993) Strength properties of ACQ treated southern pine lumber. In: Proceedings of the American wood-preservers’ association, vol 89, pp 51–60

Barnes HM, Lindsey GB (2009) Bending properties of wood treated with a new organic wood preservative system. Bioresour Technol 100:778–781

Bendtsen BA, Gjovik LR, Verrill SP (1983) Mechanical properties of longleaf pine treated with waterborne salt preservatives. USDA Forest Service Res Pap FPL-434. US Department of Agriculture, Forest Products Laboratory, Madison WI

Bergman O, Jermer J (2010) Glued laminated poles—Progress report after 30 years’ testing. International Research Group on Wood Protection report IRG/WP 10-20427

Chinese National Standard: CNS 3000 (2001) Preservative treatments of wood by pressure process. Taipei, Taiwan: Bureau of Standards, Metrology and Inspection, Ministry of Economic Affairs

EIGA, European Industrial Gases Association (2008) Environmental Newsletter No 17, http://www.eiga.org/fileadmin/docs_pubs/ENL_17-08.pdf. Accessed 1 May 2011

Evans PD, Matsunaga H, Kiguchi M (2008) Large-scale application of nanotechnology for wood protection. Nat Nanotechnol 3(10):577

Gaspar F, Cruz H, Gomes A, Nunes L (2010) Production of glued laminated timber with copper azole treated maritime pine. Eur J Wood Prod 68:207–218

Goodell B, Jellison J, Loferski J, Quarles SL (2007) Brown-rot decay of ACQ and CA-B treated lumber. For Prod J 57(6):31–33

Humar M, Žlindra D, Pohleven F (2007) Influence of wood species, treatment method and biocides concentration on leaching of copper-ethanolamine preservatives. Build Environ 42:578–583

Humar M, Petric M, Pohleven F, Destpot R (2003) Upgrading of spruce wood with ethanolamine treatment. Holz Roh- Werkst 61:29–34

Humar M, Bucar B, Pohleven F, Zlindra D (2008) Influence of ethanolamine on lignin depolymerization and copper leaching from impregnated wood. Wood Res 53:85–94

Jiang JH, Ren HQ, Lu JX, Luo XQ, Wu YZ (2007) Influence of ammoniacal copper quaternary treatments on mechanical properties of blue-stained lodgepole pine wood. J For Res, 18(3):213–216

Lebow ST (1992) Interactions of ammoniacal copper zinc arsenate (ACZA) wood preservatives with Douglas-fir. PhD Thesis, Dept Forest Products, Oregon State University, Corvallis, p 112

Loubinoux B, Malek H, Joly JP, Kilbertus G (1992) Interaction of quaternary ammonium salts with wood: influence of cation and anion structure on fixation and leaching. For Prod J 42(10):55–58

Mitchell PH, Barnes HM (1986) The effect of drying schedule on the clear wood strength of Southern Pine treated with CCA-type A. For Prod J 33(6):53–58

Ostmeyer JG, Elder TJ, Littrell BM, Taterchuk BJ, Winandy JE (1988) Spectroscopic analysis of Southern Pine treated with chromated copper arsenate. I. X-ray photoelectron spectroscopy (XPS). J Wood Chem Technol 8(3):413–439

Ostmeyer JG, Elder TJ, Winandy JE (1989) Spectroscopic analysis of Southern Pine treated with chromated copper arsenate. II. Diffuse reflectance Fourier transform infrared spectroscopy (DRIFT). J Wood Chem Technol 9(1):105–122

Preston A, Jin L, Nicholas D, Zahora A, Walcheski P, Archer K, Schultz T (2008) Field stake tests with copper-based preservatives. International Research Group on Wood Protection Document. IRG/WP 08-30459, International Research Group on Wood Protection

Resch H, Parker R (1982) Strength and stiffness of preservative-treated marine piles. Wood Fiber 14(4):310–319

Winandy JE (1989) The effect of CCA preservative treatment and redrying on the bending properties of 2 by 4 Southern Pine lumber. For Prod J 39(9):14–21

Winandy JE (1995) Effects of waterborne preservative treatment on mechanical properties: a review. In: Proceedings of the American wood-preservers’association, vol 91, pp 17–33

Yang TH, Wang SY, Lin CJ, Tsai MJ, Lin FC (2007) Effect of laminate configuration on the modulus of elasticity of glulam evaluated using a strain gauge method. J Wood Sci 53:31–39

Yang TH, Wang SY, Lin CJ, Tsai MJ (2008) Evaluation of the mechanical properties of Douglas-fir and Japanese cedar lumber and its structural glulam by nondestructive techniques. Constr Build Mater 22(2008):487–493

Yildiz UC, Temiz A, Gezer ED, Yildiz S (2004) Effects of wood preservatives on mechanical properties of yellow pine (Pinus sylvestris L.) wood. Build Environ 39:1071–1075

Acknowledgements

The authors wish to thank the National Science Council (NSC-98-2313-B-005-038- MY2) for financial support.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Yang, TH., Lin, CH., Wang, SY. et al. Effects of ACQ preservative treatment on the mechanical properties of hardwood glulam. Eur. J. Wood Prod. 70, 557–564 (2012). https://doi.org/10.1007/s00107-011-0584-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-011-0584-5