Abstract

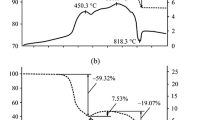

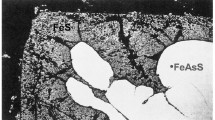

Microscopic gold inclusions in sulfide minerals cannot typically be extracted by conventional cyanidation. The gold ore must be pretreated to oxidize sulfide minerals associated with gold and to remove other minerals and chemical compounds that interfere in the cyanidation leaching process. The recovery of gold from refractory sulfidic-carbonaceous ores after roasting pretreatment was studied. With the addition of an oxygen-containing gas (e.g., air or oxygen-enriched air), sulfides of iron, zinc, copper and other metals arc transformed into solid oxides or sulfates and gaseous sulfur dioxide at elevated temperatures (e.g., 400° to 800°C). When the sulfides are oxidized, individual particles lose internal volume and become porous, allowing leaching solutions access to the gold. The structural characteristics of the calcine have a strong influence on the eventual recovery of gold by cyanidation. These characteristics are strongly dependent on the roasting conditions and roasting method. The optimum combination of particle size, roasting temperature, reaction time and oxygen concentration in the off-gas was determined for a typical refractory sulfidic-carbonaceous ore from the Carlin Trend in Nevada. The tests were run using a 150-mm laboratory rotating tube furnace and 160- and 200-mm fluid-bed pilot roasters. Laboratory results indicated that the maximum gold extraction was 92%, with the head and the leach residue containing 5.7 and 0.4 g/t (0.166 and 0.013 oz/st) Au, respectively. The maximum extraction was achieved under the following roasting conditions: a top particle size of 150 μm, a residence time of 2 hrs, a roasting temperature of 475°C and with 40% oxygen (by volume) in the off-gas. Similar results were obtained from circulating fluid bed (CFB) pilot-plant testing. The maximum gold extraction was 90%, with the head and leach residue containing of 5.1 and 0.5 g/t (0.149 and 0.015 oz/st) Au, respectively. These results were achieved with the same particle size and oxygen concentration as in the laboratory testing but with the roasting temperature of 500° to 525°C and a residence time of 30 min.

Similar content being viewed by others

References

Anonymous, 1988, “Mercur starts up its new alkaline pressure-oxidation autoclave plant,” E&MJ, June, pp. 26–31.

Armstrong, S.E. and Malhotra, D., 1992, “Can diagnostic leach procedures characterize refractory gold ores?” Randol Gold Forum, March 25–27, Vancouver, Canada, Randol International Ltd., Golden, CO, pp. 155–157.

Arriagada, F. J., and Osseo-Asare K., 1984, “Gold Extraction from Refractory Ores: Roasting Behavior of Pyrite and Arsenopyrite,” Precious Metals: Mining, Extraction, and Processing, V. Kudryk, D.A. Corrigan and W.W. Liang, eds., TMS-AIME, Warrendale, PA, pp. 367–385.

Arriagada, F.J., and Osseo-Asare, K., 1982, “Roasting of refractory auriferous concentrates,” Process Mineralogy II: Applications in Metallurgy, Ceramics, and Geology, R.D. Hagni, ed., TMS-AIME, Warrendale, PA, pp. 173–186.

Berezowsky, M.G.S., and Weir, D.R., 1989, “Factors affecting the selection of pressure oxidation for the pretreatment of refractory gold ores,” Paper Presented at the E&MJ International Gold Expo and Conference, Reno, NV, Sept. 7–9.

Brierley, J.A., Hutchins, S.R., and Brierley, C.L., 1987, “Microbial pretreatment of refractory sulfide and carbonaceous gold ores,” Paper Presented at the 116th Annual SME-AIME Meeting, Denver, CO, February 23–27.

Bruynesteyn, A., 1984, “Bioleaching of refractory gold/silver ores and concentrates,” Paper Presented at the 14th Annual CIM Hydrometallurgical Meeting, Timmins, Ontario, October 14–17.

Carvalho, T.M., 1988, “Startup of the Sherritt pressure oxidation process at Sao Bento,” Randol Gold Forum, Oct. 28–Nov. 1, Perth, Australia, Randol International Ltd., Golden, CO, pp. 152–156.

Habashi, F., 1987, “Historical metallurgical notes — One hundred years of cyanidation,” CIM Bulletin, Vol. 80, No. 905, pp. 108–114.

Hausen, D.M., 1985, “Process mineralogy of selected refractory Carlin-type ores,” CIM Bulletin, Vol. 78, No. 881, pp. 83–94.

Hausen, D.M., and Buchnam, C.H., 1984, “Study of preg robbing in the cyanidation of carbonaceous gold ores from Carlin, Nevada, “Proceedings of The Second International Congress on Applied Mineralogy in the Minerals Industry, W.C. Park, D.M. Hausen and R.D. Hagni, eds., TMS-AIME, Warrendale, PA, pp. 833–857.

Jha, M.C., 1987, “Refractoriness of certain gold ores to cyanidation — Probable causes and possible solutions,” Mineral Processing and Extractive Metallurgy Review, Vol. 2, pp. 331–352.

Lawrence, R.W., 1987, “The potential of thermophilic bacteria in the pretreatment of refractory gold ores,” Paper Presented at the Annual Meeting of BIOMINET, Sudbury, Ontario, Canada, November 3.

Lawrence, R.W., and Marchant, P.B., 1988, “Biochemical pretreatment in arsenical ore processing,” Arsenic Metallurgy Fundamentals and Applications, R.G. Reddy, J.L. Hendrix and P.B. Queneau, eds., The Minerals, Metals, and Materials Society, Warrendale, PA, pp. 199–211.

Matthews, D.C. and Henson, M.S., 1991, “Pressure Oxidation at Getchell Mine,” Technical Report, Firstmiss Gold Inc., Golconda, NV, February

Sobel, K.E., Foo, K.A., Whellock, J.G., and Canterford, J.H., 1992, “Past, present, and future of the Redox process,” Randol Gold Forum, March 25–27, Vancouver, Canada, Randol International Ltd., Golden, CO, pp. 159–164.

Thomas, K.G., 1991, “Barrick gold autoclaving processes,” Presented at World Gold 91, Gold Forum on Technology and Practices, Second Australian IMM-SME Joint Conference, Cairns, Australia, April.

Turney, J.R., Smith, R.J., and Janhunen, W.J., Jr., 1988, “the application of acid pressure oxidation to the McLaughlin refractory ore,” Precious Metals ’89, M.C. Jha and S.D. Hill, eds., The Minerals, Metals & Materials Society, Warrendale, PA, pp. 25–45.

Van Weert, G., 1988, “An update on the NITROX process,” Randol Gold Forum, January 23–24, Scottsdale, AZ, Randol International Ltd., Golden, CO, pp. 209–210.

Yannopoulos, J.C., 1987, “Roasting of Gold Refractory Ores and Concentrates — A Literature Survey,” Newmont Metallurgical Services, Danbury, CT, April.

Author information

Authors and Affiliations

Additional information

R.R. Fernández, formerly senior metallurgist with Newmont Gold, Carlin, NV

Rights and permissions

About this article

Cite this article

Fernández, R.R., Sohn, H.Y. & LeVier, K.M. Process for treating refractory gold ores by roasting under oxidizing conditions. Mining, Metallurgy & Exploration 17, 1–6 (2000). https://doi.org/10.1007/BF03402822

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03402822