Abstract

This paper reports on the results of a science project conducted during the last two years. In this project a focus was set on the rheological and setting properties as a function of the mixing energy applied in dry and wet state. A proper adjustment of mixing time and velocity even prior to the water addition is a powerful measure to enhance the compaction properties of concretes. The products are more homogenous and show improved properties with special regard to their rheology, density, open porosity and mechanical strength.

On the other hand, these encouraging results depict that results in development and research work should be read in a more qualitative way unless the preparation routine of test specimen are clearly communicated. It has to be proposed, that the mixing procedure should be an indispensable part of the procedure description.

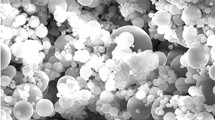

Future developments of refractory castables will even focus more consequently on the design of the particle distribution of the micro fine components in order to produce products with enhanced durability in service. However, if the matrix design turns more complex the requirements for a perfect homogenization increase exceptionally. It is necessary to define the optimum mixing energy for a proper deagglomeration without an unwanted warming of the mix that will lead to shorter pot times. As reported by many authors the setting velocity of plain cement-water suspensions is not predictable in a wanted correctness. As a spinoff of the said project, it can be shown, that the starting time of the crystallization of cement hydrate phases that correlates with the setting of the water cement suspensions is strongly dependent on the mixing energy. The starting time of the temperature increases and the distinct slope of the temperature evolution is a function of the deagglomeration degree of the cement particles during mixing.

Similar content being viewed by others

References

Bogue, R.H., Lerch, W.: Hydration of portland cement compounds. Industrial and Engineering Chemistry 26 (1934) [8] 837–847

Krause, O., Cölle, D., Schaffhauser, H., Jahn, D.: Setting Kinetics of High-dispersed Refractory Castables. Refractories Worldforum 4 (2012) [4] 81–88

Götz-Neunhoeffer, F.: Modelle zur Kinetik der Hydratation von Calciumaluminatzement mit Calciumsulfat aus kristallchemischer und mineralogischer Sicht. Erlanger Forschungen, series B, Naturwissenschaften und Medizin (2006) [29]

Schmidtmeier, D., Buhr, A., Wams, G., Kuiper, S., Klaus, S., Götz-Neunhoeffer, F., Zacherl, D., Dutton, J.: Cement hydration and strength development — how reproducible results can be achieved, Part 1. UNITECR’ (2013) 1057–1060

Schmidtmeier, D., Buhr, A., Wams, G., Kuiper, S., Klaus, S., Götz-Neunhoeffer, F., Zacherl, D., Dutton, J.: Cement hydration and strength development — how can reproducible results can be achieved, Part 2. UNITECR’ (2013) 1061–1066

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Krause, O., Klein, T., Tischer, D. et al. Setting Velocity of Cement Pastes and Monolithics — The Impact of Mixing. Interceram. - Int. Ceram. Rev. 63, 364–367 (2014). https://doi.org/10.1007/BF03401085

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03401085