Abstract

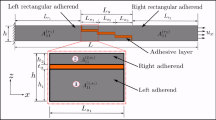

Effects of Coulomb friction and radial clamping stress on the mechanical properties at the fibre/matrix interface are considered for fibre-reinforced composites when an axial compressive stress (or indentation) is used to push on the free-surface end of the embedded fibre. The interfacial frictional shear stress, the elastic stress transfer, the length of the sliding zone, and the fibre and the matrix displacements along the fibre length are analysed analytically. Specific results are calculated for SiC-fibre-reinforced AI2O3 composites. The results show that the interfacial shear stress is not constant, but decreases along the fibre length with increasing distance from the surface. Also, the interfacial shear stress increases as the coefficient of friction, the radial clamping stress, or Poisson’s ratio of the fibre increases, which in turn results in an increase in the elastic stress transfer from the fibre to the matrix, and a decrease in both the length of the sliding zone and the fibre displacement in the loading direction. However, when Poisson’s ratio of the matrix increases, the stress transfer from the fibre to the matrix decreases.

Similar content being viewed by others

References

D. B. MARSHALL, B. N. COX and A. G. EVANS, Ada Metall 33 (1985) 2013.

A. G. EVANS and R. M. McMEEKING, ibid. 34 (1986) 2435.

D. H. GRANDE, J. F. MANDELL and K. C. C. HONG, J. Mater. Sci. 23 (1988) 311.

P. F. BECHER et al., J. Amer. Ceram. Soc. 71 (1988) 1050.

C. H. HSUEH, J. Mater. Sci. Lett. 7 (1988) 497.

R. MUKI and E. STERNBERG, Int. J. Solids Struct. 6 (1970) 66.

V. K. LUK and L. M. KEER, ibid. 15 (1979) 805.

A. P. S. SELVADURAI and R. K. N. D. RAJAPAKSE, ibid. 21 (1985) 1213.

P. LAWRENCE, J. Mater. Sci. 7 (1972) 1.

C. H. HSUEH, J. Amer. Ceram. Soc. 71 (1988) 490.

D. B. MARSHALL and W. C. OLIVER, ibid. 70 (1987) 542.

M. R. PIGGOT, “Load Bearing Fibre Composites” (A. Wheaton & Co., Exner, 1980) p. 97.

K. T. FABER, et al., J. Amer. Ceram. Soc. 69 (1986) C208.

D. K. SHETTY, ibid. 71 (1988) C107.

Z. HASHIN and B. W. ROSEN, J. Appl. Mech. 31 (1964) 223.

S. P. TIMOSHENKO and J. N. GOODIER, “Theory of Elasticity” (McGraw-Hill, New York, 1951) p. 10.

C. H. HSUEH et al., Acta Metall 34 (1986) 927.

C. H. HSUEH, J. Mater. Sci. 21 (1986) 2067.

C. H. HSUEH, P. F. BECHER and P. ANGELINI, J. Amer. Ceram. Soc. 71 (1988) 929.

M. ALONSO and E. J. FINN, “Physics” (Addison-Wesley, Reading, Massachusetts, 1970) p. 113.

C. H. HSUEH, “Fiber Pullout Versus Push-down for Fiber-Reinforcement Ceramic Composites with Frictional Interfaces” in press.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hsueh, CH. Interfacial friction analysis for fibre-reinforced composites during fibre push-down (indentation). J Mater Sci 25, 818–828 (1990). https://doi.org/10.1007/BF03372168

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03372168