Abstract

The introduction of modern materials has offered engineers tools to develop novel solutions to satisfy the demands of consumers and regulators. Advanced high strength steels combine high strength with good formability and weldability. The increased strength levels allow manufacturers to reduce sheet gauges (thus lowering weight) whilst retaining performance in safety critical areas of the construction. However issues have been reported in literature concerning the failure behaviour of advanced high strength steels. The performance of welded joints is usually evaluated using coupon tests under either normal or shear tensile loading. The actual loading of these joints in an automotive structure may be quite different, especially concerning the angle in which the load is applied.

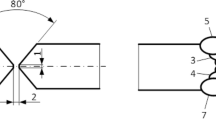

In this report an overview is given of published results on the performance of welded joints in automotive applications. Next the results from a series of resistance spot and laser welded joints in different steel sheet materials (HSLA and DP of varying thickness) subjected to tensile tests under varying loading angles are presented. The focus is on resistance spot welded joints, but the results are compared to similar tests performed with laser welded joints. The performance of the welded joints in terms of failure mode and strength are analysed, and the possible implications for automotive applications are discussed.

Finally some work using finite element simulations is presented. Here the characteristics of the base material and welded joints of different grades of materials are evaluated to investigate the differences in performance in tensile testing.

It is concluded that the thickness of the materials is the main parameter determining the failure characteristics of materials. The grade (HSLA or DP) is less of a factor determining failure mode. The fact that joints in DP steel perform as well as HSLA steels allows designers and engineers to use the advanced high strength steel without having to worry about unpredictable failure behaviour leading to decreased performance for safety critical applications.

Similar content being viewed by others

References

BMW Group Standard GS 96002-2: Widerstandspunktschweissen (RP) von Stählen, (Resistance Spot Welding (RP) of Steels).

American Iron and Steel Institute: Anatomy of a Crash: The most important 100 Milliseconds of Your Life, Poster.

den Uijl N.J. and Smith S.: Resistance Spot Welding of Advanced High Strength Steels for the Automotive Industry, Proceedings of the 4th International Seminar on Advances in Resistance Welding, W. Zhang and A. Eder (Eds.), Wels, Austria, 2006.

Khan M.I., Kunz M.L., Biro E. and Zhou Y.: Microstructure and Mechanical Properties of Resistance Spot Welded Advanced High Strength Steels, Materials Transactions, Vol. 49, No. 7, 2008.

Baltazar V.H., Hernandez, Kuntz M.L., Khan M.I. and Zhou Y.: Influence of Microstructure and Weld Size on the 151 Mechancial Behaviour of Dissimilar AHSS Resistance Spot Welds, Science and Technology of Welding and Joining, Vol. 13, No. 8, 2008.

Lópes-Cortéz V.H. and Reyes-Valdés F.A.: Understanding Resistance Spot Welding of Advanced High-Strength Steels, Welding Journal, Vol. 87, December 2008.

Mimer M., Svensson L-E. and Johansson R.: Possibilities to Improve Fracture Behaviour in Resistance Spot Welds of EHSS and UHSS by Process Modifications, Proceedings of the 3rd International Seminar on Advances in Resistance Welding, Zhang W. and Xu P. (Eds.), Berlin, Germany, 2004.

AWS D8.1M, 2007: Specification for Automotive Weld Quality — Resistance Spot Welding of Steel, 2007.

Nikoosohbat F., Kheirandish S., Goodarzi M., Pouranvari M. and Marashi S. P. H.: Microstructure and failure behaviour of resistance spot welded DP980 dual phase steel, Materials Science and Technology, Vol. 26, No. 6, 2010.

Bouzekri M., Dancette S., Dupuy T., Lens A., Nait Oultit B., Massardier V. and Fabrègue D.: An Investigation of Failure Types in High-Strength Steel Resistance Spot Welds, Doc. IIW-1973-08, Welding in the World, Vol. 54, No. 3/4, 2010.

Westgate S.: The Resistance Spot Welding of High and Ultra-high Strength Steels, Proceedings of the 3rd International Seminar on Advances in Resistance Welding, Zhang W. and Xu P. (Eds.); Berlin, Germany; 2004.

Pedersen K.R., Harthøj A., Friis K. L., Bay N., Somers M.A.J. and Zhang W.: Microstructure and Hardness Distribution of Resistance Welded Advanced High Strength Steels, Proceedings of the 5th International Seminar on Advances in Resistance Welding, Toronto, Canada, Zhang W. and Scotchmer N. (Eds.), 2008.

den Uijl N.J.: Modelling the Influence of Resistance Spot Welding on Material Properties, Proceedings of the 16th International Conference on Computer Technology in Welding and Manufacturing and the 3rd International Conference on Mathematical Modelling and Information Technologies in Welding and Related Processes; Lucas W. and Makhnenko V.I. (Eds.), Kiev, 2006.

denUijl N.J., Nishibata H., Smith S., Okada T., van der Veldt T., Uchihara M. and Fukui K.: Prediction of post weld hardness of advanced high strength steels for automotive application using a dedicated carbon equivalent number, Doc. IIW-1873-07, Welding in the world, Vol. 52, No. 11/12 2008.

Smith S., den Uijl N.J., van der Veldt T., Okada T., Uchihara M., Fukui F.: The effect of ageing on the spot weld strength of AHSS and the consequences for testing procedures, Doc. IIW-1976-08, Welding in the World, Vol. 54, No. 1/2, 2010.

Marya M. and Gayden X.Q.: Development of Requirements for Resistance Spot Welded Dual-Phase (DP600A) Steels; Part 1 — The Causes of Interfacial Fracture, Welding Journal, Vol. 84, November 2005.

Gould J.E., Khurana S.P. and Li T.: Predictions of Microstructures when Welding Automotive Advanced High Strength Steels, Welding Journal, Vol. 50, May 2006.

Chao Y.J.: Failure Mode of Spot Welds: Interfacial versus Pullout, Science and Technology of Welding and Joining, Vol. 8, No. 2, 2003.

Tumuluru M.: Some Considerations in the Resistance Spot Welding of Dual Phase Steels, The 5th International Seminar on Advances in Resistance Welding, Toronto, Canada, 2008.

Larsson J.K., Lungren J., Asbjörnsson E. and Andersson H.: Extensive Introduction of Ultra High Strength Steels Sets New Standards for Welding in the Body Shop, IIW-1972-98, Welding in the World, Vol. 53, No. 5/6, 2009.

Radakovic D.J. and Tumuluru M.: Predicting Resistance Spot Weld Failure Modes in Shear Tension Tests of Advanced High-Strength Automotive Steels, Welding Journal; Vol. 87, April 2008.

Zhang H. and Senkara J.: Resistance Welding; Fundamentals and Applications, Taylor and Francis, ISBN 0-8493-2346-0, 2006.

Volvo Coporate Standard STD 8631, 14: Weldability of sheet metal, spot welding.

Maotao Z., Zhong W. and Weiwei Z.: Static Strength and Fatigue Analysis of the Automobile Sub-Frame by FEA Simulation Method and Fatigue Test, Advanced Materials Research, 179-180, 2011.

Kumagai K., Shirooka M., Ohachi J. and Ogawa T.: Rupture Modeling of Spot Welds Suitable for Crash FE Analysis in Vehicle Development Process, 6th European LS-DYNA Users’ Conference, Gothenburg, Sweden, 2007.

Wood P.K.C., Schley C.A., Beaumont R., Walker B., Dutton T. and M.A. Buckley: Modelling and Predicting Spotweld Failures in Automotive Crash Structures, 7th European LS-DYNA Users’ Conference; Salzburg, Austria; 2009.

Wolf K., Schilling R., Lütjens J., Wallmersperger T., Jankowski U., Sihling D., Wiegand K. and Heuse M.: Coupled FEM Calculations — A CAE Tool to Improve Crash-Relevant Automotive Body Components by Local Hardening, 7th European LS-DYNA Users’ Conference, Salzburg, Austria, 2009.

Ueda H., Okamura K., Nakayama E., Fujimoto H., Okada T., Ushihara M. and M. Fukumoto: Evaluation of Crash Performance in Steel Sheet Parts Coupled with Fracture Prediction of Spot Welded Joints, F2010-C-128, FISITA 2010 World Automotive Congress, Budapest, Hungary, 2010.

IIW: Technical Report, 1969, IIW doc. IX-535-67.

VDEh standard SEP1220-3 — Testing and Documentation Guideline for the joinability of steel sheet, Part 3, laser welding.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

den Uijl, N., Azakane, F., Kilic, S. et al. Performance of Tensile Tested Resistance Spot and Laser Welded Joints at Various Angles. Weld World 56, 143–152 (2012). https://doi.org/10.1007/BF03321404

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03321404