Abstract

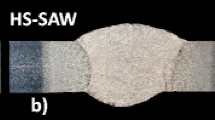

The welding of block joints in shipbuilding often requires much effort as the fabrication without margins sometimes leads to large gaps between them, The high constraint during the welding process can lead to unfavourable high residual stresses, For this reason, a project was undertaken to investigate whether butt joints welded with larger gaps fulfill the requirements, The objective was to determine the sufficient strength of welds performed with gaps of up to 30 mm, For this purpose, butt joints of 250 mm-wide and 15 mm-thick plates made of mild and higher-tensile steel, welded with different gaps, were investigated with respect to their fracture toughness and fatigue strength, Welding was performed under definite, elastic restraints corresponding to the stiffness of the surrounding ship structure, Apart from the width of the gap, further parameters were varied including the welding method (string-bead, weaving technique), From the fracture mechanics point of view, no objections exist regarding the large gap of 30 mm welded by weaving, The specimens welded with the string-bead technique achieved relatively low, partly uniform critical fracture toughness values, The fatigue tests confirm the results of FITN ET, Despite a small decrease of fatigue strength, the weaving technique agrees with the existing fatigue class, The string-bead technique results in a fatigue class which is consistent with the nominal stress approach, However, the local approaches result in non-conservative fatigue assessments and therefore do not fulfill the requirements, Generally, fatigue as well as fracture investigations indicated a clear influence of welding technique on the fatigue and fracture strength of a weld.

Similar content being viewed by others

References

Savu D. and Huismann G.: Verschweißen großer Luftspalte an Stößen von Schiffbaublöcken, Joining by welding of two volume sections of a ship using wide gaps, Final Report BMBF-Research Project 03SX133B/ Part P3.1, Universität der Bundeswehr, Hamburg, 2003 (in German).

Germanischer Lloyd: Classification Rules II — Materials and Welding, Part 1; Metallic Materials, Chapter 2: Steel and Iron Materials, Self-Publishing, Hamburg, 2009.

Cicero S, Yeni C. and Kocak M.: Fracture analysis of strength undermatched Al-Alloy welds in edge cracked tensile panels using FITNET procedure, Fatigue & Fracture of Engineering Materials & Structures, 2008, vol. 31, no. 9, pp. 738–753.

FITN ET 2006 — Fracture — Fatigue — Creep-Corrosion, Proceedings of the International Conference on Fitnet-for-Service (Ed. M. Kocak), GKSS Research Center, Geesthacht, 2006.

Zacke S., Fricke W, Eren S.E. and Kocak M.: Effects of welding technique, material and loading on the fatigue strength of butt joints welded with wide gaps, Proceedings of the International Conference of Advances in Welding Science and Technology for Construction, Energy and Transportation Systems (AWST-2010), Istanbul, 2010.

Hobbacher A.: Recommendations for fatigue design of welded joints and components, Doc. IIW-1823, WRC Bulletin 520, Welding Research Council, Inc., New York, 2009.

Radaj D., Sonsino CM., Fricke W: Fatigue assessment of welded joints by local approaches, Woodhead Publishing Limited, 2nd Ed, Cambridge, 2006.

Franc2D/L. http://www.cfg.cornell.edu/software/franc3d_casca.htm

Goo B.C., Yang S.Y, Seo J.W: Fatigue life evaluation model for welded joints with residual stresses, Key Engineering Materials, 2005, vols. 297-300 Advances in Fracture and strength, pp. 762-767.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fricke, W., Zacke, S., Koçak, M. et al. Fatigue and Fracture Strength of Ship Block Joints Welded with Large Gaps. Weld World 56, 30–39 (2012). https://doi.org/10.1007/BF03321333

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03321333