Abstract

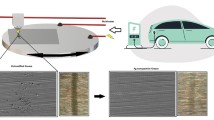

Alloying elements are added to the zinc used in the hot-dip galvanization of sheet steel to control the properties and appearance of the resulting coating. For example, aluminum is added to improve the corrosion resistance and adherence of the coating. Other additions, such as antimony, are added to control the grain size and, thus, the appearance of the coating. The concentrations of these alloying elements may change during the process, either deliberately according to product specifications or due to factors such as preferential oxidation. These changes may require replenishment of a depleted alloying element or adjustments in other processing parameters to maintain optimal efficiency. Intelligent adjustments require knowledge of the alloy composition, which requires inline measurement of the concentrations of alloying elements. This article presents recent developments in chemical sensors for use in hot-dip galvanization. In particular, electrochemical sensors for measuring the concentrations of aluminum and antimony in molten zinc are reviewed.

Similar content being viewed by others

References

V. Jagannathan, “Emerging Technologies in the Hot-Dip Coating of Automotive Sheet Steel,” JOM, 45 (8) (1993), pp. 48–51.

A.R.P. Ghuman and J.I. Goldstein, “Reaction Mechanisms for the Coatings Formed During the Hot Dipping of Iron in 0 to 10 Pct Al-Zn Baths at 450°C to 700°C,” Metall. Trans., 2 (10) (1971), pp. 2903–2914.

F.A. Fasoyinu and F. Weinberg, “Spangle Formation in Galvanized Sheet Steel Coatings,” Metall. Trans. B, 21B (3) (1990), pp. 549–558.

Y. Yoshitaka, M. Arai, and T. Nakamori, “Effect of Al in Molten Zinc on Adhesion Strength in Galvannealed Steel,” Tetsu-to Nagane, 80 (8) (1994), pp. 67–72.

L.A. Rocha and M.A. Barbosa, “Microstructure, Growth Kinetics, and Corrosion Resistance of Hot-Dip Galvanized Zn-5% Al Coatings” Corrosion, 47 (7) (1991, pp. 536–541.

H. Yamaguchi and Y. Hisamatsu, “Reaction of Dross Formation in Continuous Galvanizing,” Tetsu-to Hagane, 60 (1) (1974), pp. 96–103.

N.-Y. Tang, “Refined 450°C Isotherm of Zn-Fe-Al Phase Diagram,” Mater. Sci. Tech., 11 (9) (1995), pp. 870–873.

K.L. Un et al., “Growth Behavior and Corrosion Resistance of 5% Al-Zn Coating,” Corrosion, 49 (9) (1993), pp. 759–762.

P.G. Caceres et al., “Mechanisms of Formation and Growth of Intennetallic Layer During Hot Dipping of Iron in Zn-3AI and Zn-6AI Baths,” Mater. Sci. Tech., 2 (8) (1986), pp. 871–877.

J.H. Selverian, A.R. Marder, and M.R. Notis, “The Reaction Between Solid Iron and Al-Zn Baths,” Metall. Trans. A, 19A (5) (1988), pp. 1193–1203.

G.J. Harvey and P.D. Mercer, “Aluminum-Rich Alloy Layers Formed During the Hot Dip Galvanizing of Low Carbon Steel,” Metall. Trans., 4 (2) (1973), pp. 619–621.

S.J. Makirnattila et al., “The Effect of Intermetallic Layer on the Adherence of a Hot-Dip Galvanized Coating,” Scripta Metall., 19 (2) (1985), pp. 211–214.

R.F. Lynch, “Galfan Stretches Standard Performance,” ASTM Standardization News, 18 (3) (1990), pp. 26–30.

G.J. McManus, “Galfan Coating Finds Its Niche,” Iron Age, 8 (9) (1992), pp. 43–44.

H.P. Ferrett, “New Developments in the Application of Galfan in the Steel Wire Industry,” Wire J. Int., 20 (9) (1987), pp. 178–189.

H.E. Townsend et al., “Hot-Dip Coated Sheet Steels-A Review,” Materials Performance, 25 (8) (1986), pp. 36–46.

S.-I. Pyun et al., “The Anodic Behaviour of Hot-Galvanized Zinc Layer in Alkaline Solution,” Corrosion Science, 36 (5) (1994), pp. 827–835.

K.-L. Lin, C.-F. Yang, and J.-T. Lee, “Correlation of Microstructure with Corrosion and Electrochemical Behavior of the Batch-Type Hot-Dip Al-Zn Coatings: Part I. Zn and 5% Al-Zn Coatings,” Corrosion, 47 (1) (1991), pp. 9–17.

D.R Salinas and J.B. Bessone, “Electrochemical Behavior of Al-5%Zn-0.1%Sn Sacrificial Anode in Aggressive Media: Inf1uence of Its Alloying Elements and the Solidification Structure,” Corrosion, 47 (9) (1991), pp. 6–74.

T.-P. Cheng et al., “Electrochemical Behavior of Galvanized Al-Zn Coatings in Saturated Ca(OH)2 Solution,” Corrosion, 47 (6) (1991), pp. 436–442.

K.-L. Lin, C.-F. Yang, and J.-T. Lee, “Correlation of Microstructure with Corrosion and Electrochemical Behavior of the Batch-Type Hot-Dip Al-Zn Coatings: Part II. 55% Al-Zn Coatings, Corrosion, 47 (1) (1991), pp. 17–23.

H.E. Townsend and C.F. Meitzner, “Corrosion Resistance of Zinc/4% Aluminum and Zinc/7% Aluminum Alloy Coatings Compared to Zinc and Zinc/54% Aluminum Alloy Coatings,” Materials Performance, 22 (1) (1983) p. 54.

H.E. Townsend and J.C. Zoccola, “Atmospheric Corrosion Resistance of 55% Al-Zn Coated Sheet Steel: 13 Year Test Results,” Materials Performance, 18 (10) (1979), pp. 13–20.

H.E. Townsend and A.R. Borzillo, “Twenty-Year AtmospheriC Corrosion Test of Hot-Dip Coated Sheet Steel,” Materials Performance, 26 (7) (1987), pp. 37–41.

F.A. Fasoyinu and F. Weinberg, “The Surface-Topography of Sheet Steel Galvanized Coatings,” Can. Metall. Quart., 32 (2) (1993), pp. 185–192.

S. Chang and J.C. Shin, “Effect of Antimony Addition on Hot Dip Galvanized Coating,” Corrosion, 36 (8) (1994), pp. 1425–1436.

D. Jaffrey, J.D. Browne, and T.J. Howard, “The Cracking of Zinc Spangles on Hot-dipped Galvanized Steel,” Metall. Trans. B, 11B (6) (1980), pp. 631–635.

H.E. Biber, “Scanning Auger Microprobe Study of Hot-Dipped Regular-Spangle Galvanized Steel: Part I. Surface Composition of As-Produced Sheet,” Metall. Trans. A, 19A (6) (1988), pp. 1603–1608.

R. Gutenberg, J. Lait, and F. Weinberg, “Changing Al and Ph Bath Concentrations in Galvanized Sheet Steel,” Can. Metall. Quart., 29 (4) (1990), pp. 307–312.

F.E. Goodwin, M.P. Roman, and J.J. Hogan, “Recent Developments in Galfan-Coated Wire,” Wire J. Int., 23 (10) (1990), pp. 48–64.

H.E. Biber, “Scanning Auger Microprobe Study of Hot-Dipped Regular-Spangle Galvanized Steel: Part I. Surface Composition of Chromated Sheet,” Metall. Trans. A, 19A (6) (1988), pp. 1609–1612.

J.W. Fergus, “Electrochemical Magnesium Sensors for Aluminum Processing,” JOM, 47 (11) (1995), pp. 36–41.

J.W. Fergus and S. Hui, “Solid Electrolyte Sensor for Measuring Magnesium in Molten Aluminum,” Metall. Mater. Trans. B, 26B (6) (1995), pp. 1289–1291.

B.L. Tiwari and B.J. Howie, “Determination of Magnesium in Molten Aluminum Alloy Using an Electrochemical Sensor,” Light Metals 1989, ed. P.G. Campbell (Warrendale, PA: TMS, 1989), pp. 895–902.

B.L. Tiwari and B.J. Howie, “Electrochemical Probe for Measuring Magnesium Concentration in Molten Aluminum,” U.S. patent 4,601,810 (22 July 1986).

S. Larose, A. Dubreuil, and A.D. Pelton, “Solid Electrolyte Probes for Magnesium, Calcium and Strontium in Molten Aluminum,” Solid State Ionics, 47 (1991), pp. 287–295.

X.Y. Yan, D.E. Langberg, and W.J. Rankin, “Thermodynamic Properties of Zinc-Rich Zinc-Aluminum Melts,” Metall. Trans. B, 24B (6) (1993), pp. 1037–1044.

S. Yamaguchi et al., “Development of Aluminum Sensor for Molten Zinc Bath Using Composite Salt Electrolyte,” CAMP-ISIJ, 4 (1991), p. 669.

S. Yamaguchi et al., “Development of Al Sensor in Zn Bath for Continuous Galvanizing Processes,” CALVATECH ′95 Conf. Proc. (1995), pp. 647–655.

D. Fray, “Solid Electrolytes and the Analysis of Molten Metals,” Chem. Ind. (15 June 1995), pp. 445–448.

S. Matsubara et al., “Determination of Aluminum Sensor for Molten Zinc Bath Using Zirconia Solid Electrolyte,” Tetsu-to Hagane, 79 (2) (1993), pp. 180–186.

T.C. Wilder, “Method for Determining the Concentration of a Metal in an Alloy Melt,” U.S. patent 3,816,269 (11 June 1974).

G.B. Barbi, “ThermodynamiC Functions by E.M.F. Measurements on Solid Galvanic Cells in Non-Stationary Conditions: System Al + Al2O3,” Trans. Faraday Soc., 62 (1966), pp. 1589–1595.

T.A. Ramanarayanan and W.L. Worrell, “Limitations in the Use of Solid State Electrochemical Cells for High-Temperature Equilibrium Measurements,” Can. Metall. Quart., 13 (2) (1974), pp. 325–329.

B.C.H. Steele and C.B. Alcock, “Factors Influencing the Performance of Solid Oxide Electrolytes in High-Temperature Thermodynamic Measurements,” Trans. Metall. Soc. AIME, 233 (1965), pp. 1359–1367.

T.H. Etsell and S.N. Flengas, “The Electrical Properties of Solid Oxide Electrolytes,” Chem. Rev., 70 (3) (1970), pp. 339–376.

C.B. Alcock and B. Li, “Electrochemical Sensor for Determining the Level of a Certain Metal in Metals and Alloys,” U.S. patent 5,256,272 (26 October 1993).

S. Matsubara et al., “Determination of Aluminum Content in Molten Zinc by the E.M.F. Method Using CaF, Solid Electrolyte,” J. Japan. Inst. Metals, 58 (1994), pp. 929–935.

J.W. Fergus and S. Hui, unpublished work.

L.B. Rubin, K.L. Komarek, and E. Miller, “thermodynamic Properties and Compound Cluster Formation in Liquid Zinc-Antimony Alloys,” Z. Metallkde., 65 (3) (1974), pp. 191–199.

B. Onderka and K. Fitzner, “Thermodynamic Study of Sb-Te Alloys by EMF Measurements Using Solid Zirconia Electrolyte,” Z. Metallkde., 86 (5) (1995), pp. 313–318.

X.Y. Yan, D.E. Langberg, and W.J. Rankin, “Preparation and Characterization of Polycrystalline Lead-Exchanged Sodium Beta″-Alumina and Its Use as a Ph2+ Ion-Conducting Electrolyte for Galvanic Cells,” Metall. Mater. Trans. B, 26B (5) (1995), pp. 1005–1011.

G.M. Kale, A.J. Davidson, and D.J. Fray, “Solid-State Sensor for Measuring Antimony in Non-Ferrous Metals,” Solid State Ionics (June 1996), in press.

D.J. Fray and R.V. Kumar, “Method for Measuring a Minor Element in a Molten Metal,” U.S. patent 5,192,404 (09 March 1993).

J.W. Fergus and S. Hui, “Solid Electrolyte Based Galvanic Cell for Measuring the Antimony Concentration in Molten Zinc,” J. Electrochern. Soc. 143 (8) (1996) pp. 2498–2502.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Fergus, J.W. The status of chemical sensors for hot-dip galvanization. JOM 48, 38–41 (1996). https://doi.org/10.1007/BF03223072

Issue Date:

DOI: https://doi.org/10.1007/BF03223072