Abstract

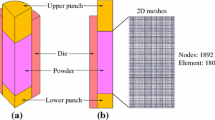

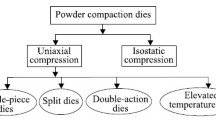

In this study, the friction effect on the powdered metal compaction process has been analyzed by applying finite element methods. A plasticity theory applicable to powdered metal compaction is summarized and a variational form for finite element analysis is described. The compaction processes of the axisymmetric solid cylinder are simulated for different compact geometries in single-action pressing. Efforts are focused on the pressure transmitted between the upper and lower punches through the compact and density distributions within the compacts. The numerical results show that: (1) the friction condition between the metal powder and the dies can be determined simply from the force data transmitted by a single such action compaction test and the simulation results; (2) the density variations within the compacts rely on such compact geometry as the height to diameter ratio and the frictional conditions between powder and dies; the (3) additional useful information obtained includes the Min/Max density ratio within the compacts.

Similar content being viewed by others

References

J. W. Wisker and P. K. Johns,Metal Powder Industries Federation 7, 33 (1974).

P. K. Jones,New Perspectives in Powder Metallurgy, vol. 6, Plenum Press, New York (1973).

B. B. Hwang and S. Kobayashi,Int. J. Mach. Tools Manufact. 31, 123 (1991).

Serope Kalpakjian,Manufacturing Processes for Engineering Materials, 2nd Ed., p. 687, Addison-Wesley publishing company Inc., USA (1991).

B. B. Hwang and S. Kobayashi,Int. J. Mach. Tools Manufact. 30, 309 (1990).

B. B. Hwang,Deformation Characterization of Powdered Metals in Compaction and Application of the Finite Element Method to Compaction Processes, Berkley University, p. 25, Berkley University, USA (1991).

R. P. Seeling,Trans, AIME Metals Tech., Aug., 171 (1947).

R. Kamm, M. Steinberg and J. Wulff,Trans. AIME Metals Tech., Feb., 171 (1947).

M. E. Shank and J. Wulff,Metals Trans. 185, 561 (1949).

R. W. Heckel,Trans. Met. Soc. AIME 221, 671 (1961).

K. Okimoto, M. Oyane and S. Shima,Jpn. Soc. Powder Powder Metal 22, 178 (1975).

P. Duwez and L. Zwell,Metals Trans., Feb., 137 (1949).

S. Kobayashi, S. I. Oh and T. Altan,Metal Forming and the Finite Element Method, p. 30, Oxford University Press, Oxford (1989).

B. B. Hwang and S. Kobayashi,Int. J. Mach. Tools Manufact. 34, 424 (1994).

J. C. Wang and A. V. Nadkami,Powder Metall. 37, 371 (1981).

W. A. Nystrom,Metal Powder Industries Federation 7, 142 (1980).

S. M. Doraivelu, H. L. Gegel, J. S. Gunasekara, J. C. Malas, J. T. Morgan and J. F. Thomas,Int. J. Mech. Sci. 26, 527 (1984).

J. S. Hirschhorn,Introduction to Powder Metallurgy, p. 1, APMI, New Jersey (1976).

S. I. Oh, W. T. Wu and J. J. Park,Proc. 2nd ICPT, p. 961, Sturtgart, West Germany (1987).

Fritz V. Lenel,Powder Metallurgy-Principles and Applications p. 99, Metal Powder Industries Federation, USA (1980).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hwang, BB. An analysis of the powdered metal compaction process in solid cylind cal parts. Metals and Materials 5, 73–83 (1999). https://doi.org/10.1007/BF03026007

Issue Date:

DOI: https://doi.org/10.1007/BF03026007