Abstract

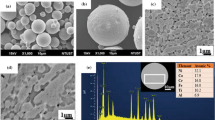

Two Fe-Cr-B based gas atomized powders, Armacor M and 16, were thermally sprayed on a low carbon steel substrate, using the HVOF (High Velocity Oxygen Fuel) process. Armacor M was also weld-surfaced with the PTA (Plasma Transferred Arc) process. The resultant deposits were subsequently characterized, using X-ray diffraction, scanning electron microscopy, and microhardness measurement. The effects of heat treatment were also studied for HVOF-sprayed coatings. The wear performance of the coatings was investigated by two-body abrasive wear tests. The results of microstructural analysis of as-sprayed deposits revealed oxide and boride phases such as Fe3O4 and Cr1.65F0.35B0.96 in an α matrix for the HVOF-sprayed Armacor 16 coating, and only the boride phases (Cr1.65F0.35B0.96 and Cr2B) in an α matrix for the HVOFsprayed Armacor M coating. PTA weld-surfaced Armacor M coating contains needle-type long precipitates of Cr2B) and Cr1.65F0.35B0.96, in the α matrix. The hardness of the HVOF-sprayed Armacor 16 coating after heat treatment was substantially less than that of the as-sprayed coating due to the phase transformation from α to γ phase. Heat treatments of the HVOF-sprayed Armacor M coating did not produce changes in phase and its hardness decreased as compared to that of the as-sprayed coating. While HVOF-sprayed and PTA weld-surfaced Armacor M coatings have the same hardness, the latter shows better abrasive wear resistance because of the size and orientation of its boride phases. The broadening of the XRD patterns and the increase in hardness after wear testing suggest that the transformation from the crystalline to the amorphous structure occurred on the uppermost layer during wear testing.

Similar content being viewed by others

References

J. W. Luster, G. R. Heath and P. A. Kammer,Materials and Manufacturing Processes 11, 855 (1996).

A. Borisova, Y. Borisov, V. Korzhyk and V. Bobrik, inThermal Spraying: Current Status and Future Trends (ed., A. Ohmori), p. 749, Kobe, Japan (1995).

K. Kishitake, H. Era and F. Otsubo,J. Thermal Spray Teehnol. 5, 1145 (1996).

K. Kishitake, H. Era and F. Otsubo,J. Thermal Spray Technol. 5, 283 (1996).

H. Miura, S. Isa and K. Omuro,Trans. of the Japan Inst. of Metals 15, 284 (1984).

D. M. Scruggs,US Patent No. 4725512 (1988).

D. M. Scruggs,Welding Journal 7, 27 (1992).

D. M. Scruggs, inThermal Spray Coatings: Properties, Processes and Applications (ed., T.F. Bemecki), p. 147, ASM, Pittsburgh, Pennsylvania, USA (1991).

D. M. Scruggs, inThermal Spray: Meeting the Challenges of the 21th Century (ed., C. Coddet), p. 249, Nice, France (1998).

H. W. Jin, C. G. Park and M C. Kim, inThermal Spray: Meeting the Challenges of the 21th Century (ed., C. Coddet), p. 111, Nice, France (1998).

H. W. Jin, Y. M. Rhyim, C. G. Park and M. C. Kim,Metals and Materials 3, 60 (1997).

A. H. Dent, A. J. Hoflock, D. G. McCartney and S. J. Harris, inThermal Spray: A United Forum for Scientific and Technological Advances (ed., C. C. Berndt), p. 917, Indianapolis, Indiana, USA (1997).

R. B. Schwarz and W. L. Johnson,Phys. Rev. Lett. 42, 63 (1983).

H. J. Kim, C. H. Kim, J. H. Park,RIST Research Project Report, No. 95A036 (1996).

H. J. Kim, Y. G. Kweon and R. W. Chang,J. Thermal Spray Tech. 3, 169 (1994).

V. Ramnath and N. Jayaraman,Mater. Sci. Tech. 5, 382 (1989).

K. H. Zum Gahr, inSurface Modification Technologies VIII (eds., T. S. Sudarshan and M. Jeandin), p. 3, The Institute of Materials, Nice, France (1995).

H. J. Kim and Y. G. Kweon,Wear 193, 8 (1996).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kim, HJ., Grossi, S. & Kweon, YG. Characterization of Fe-Cr-B based coatings produced by HVOF and PTA processes. Metals and Materials 5, 63–72 (1999). https://doi.org/10.1007/BF03026006

Issue Date:

DOI: https://doi.org/10.1007/BF03026006