Abstract

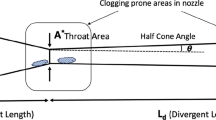

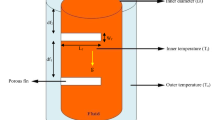

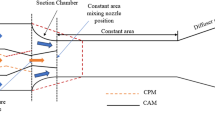

This study examines the influence of geometry on the internal flow and macroscopic behavior of the spray in Diesel nozzles. For this investigation, two bi-orifice nozzles were employed : one cylindrical and one conical. The first step is to use a non-destructive characterization method which is based on the production of silicone moulds so that the precise internal geometry of the two nozzles can be measured. At this stage the nozzles have been characterized dimensionally and therefore the internal flow can be studied using CFD calculations. The results gained from this experiment make it possible also to ascertain the critical cavitation conditions. Once the critical cavitation conditions have been identified, the macroscopic parameters of the spray can be studied in both cavitating and non-cavitating conditions using a test rig pressurized with nitrogen and with the help of a image acquisition system and image processing software. Consequently, research can be carried out to determine the influence that cavitation has on macroscopic spray behavior. From the point of view of the spray macroscopic behavior, the main conclusion of the paper is that cavitation leads to an increment of the spray cone angle. On the other hand, from the point of view of the internal flow, the hole outlet velocity increases when cavitation appears. This phenomenon can be explained by the reduction in the cross section of the liquid phase in the outlet section of the hole.

Similar content being viewed by others

Abbreviations

- A :

-

Total surface of the nozzle orifice at the outlet

- A o :

-

Surface of one orifice at the outlet

- AR :

-

Area reduction of the nozzle orifices

- C a :

-

Contraction coefficient at the orifice outlet

- C c :

-

Nurick contraction coefficient

- C d :

-

Discharge coefficient

- C v :

-

Velocity coefficient at the orifice outlet

- CN :

-

Cavitation Number

- D eq :

-

Equivalent diameter

- D i :

-

Diameter at the orifice inlet

- D m :

-

Diameter at the middle of the orifice

- D o :

-

Diameter at the orifice outlet

- F :

-

Coefficient of the discharge coefficient regression

- G :

-

Coefficient of the discharge coefficient regression

- \(\dot m\) :

-

Mass flow rate of the nozzle

- \(\dot m_o \) :

-

Mass flow rate of one orifice of the nozzle

- \(\dot M_o \) :

-

Momentum flux at the orifice outlet

- Pi :

-

Injection pressure

- Pb :

-

Downstream pressure (backpressure)

- Pv :

-

Vaporisation pressure

- Ra :

-

Upper rounding radius at the inlet orifice

- Rb :

-

Lower rounding radius at the inlet orifice

- Re :

-

Reynolds number

- S :

-

Spray penetration

- t :

-

Time

- Uo :

-

Velocity at the orifice outlet

- Uth :

-

Theoretical velocity

- P :

-

Pressure differential, ΔP=Pi-Pb

- ρ:

-

Gasoil density

- ρo :

-

Air density

- θ:

-

Spray cone angle.

- θ/2:

-

Spray cone semi-angle

- μ:

-

Dynamic viscosity teν Kinematic viscosity

- crit :

-

Cavitation critical conditions

References

Arcoumanis, C. and Gavaises, M., 1998, “Linking Nozzle Flow with Spray Characteristics in a Diesel Fuel Injection System,”Atomization and Sprays, Vol. 8, pp. 307–347.

Arcoumanis, C., Flora, H., Gavaises, M., Kampanis, N. and Horrocks, R., 1999, “Investigation of Cavitation in a Vertical Multi-Hole Diesel Injector,” SAE Paper 1999-01-0524.

Arcoumanis, C., Badami, M., Flora, H. and Gavaises, M., 2000, “Cavitation in Real-Size Multi-Hole Diesel Injector Nozzles,”SAE Paper 2000-01-1249.

Badock, C., Wirth, R., Kampmann, S. and Tropea, C., 1997, “Fundamental Study of the Influence of Cavitation on the Internal Flow and Atomization of Diesel Sprays,”Proc. 13th ILASS-Europe 97, Florence, July, 8-10, pp. 53,–59.

Badock, C., Wirth, R. and Tropea C., 1999, “The Influence of Hydro-Grinding on Cavitation Inside a Diesel Injection Nozzle and Primary Break-Up Under Unsteady Pressure Conditions,”Proc. 15th ILASS-Europe 99, Toulouse, July 5–7.

Bergwerk, W., 1959, “Flow pattern in Diesel Nozzle Spray Holes,” Proc. Inst. Mech. Engrs, Vol. 173, No. 25.

Blessing, M., Konig, G., Kruger, C., Michels, U. and Schwarz, V., 2003, “Analysis of Flow and Cavitation Phenomena in Diesel Injection Nozzles and its Effects on Spray and Mixture Formation,”SAE Paper 2003-01-1358.

Bunnell, R. A. and Heister, S. D., 2000, “Three-Dimensional Unsteady Simulation of Cavitating Flows in Injector Passages,”Journal of Fluids engineering (ASME), December, Vol. 122, pp. 791–797.

Chaves, H., Knapp, M. and Kubitzek, A., 1995, “Experimental Study of Cavitation in the Nozzle Hole of Diesel Injectors Using Transparent nozzles,”SAE Paper 950290.

Choi, S.-H., Jeon, C.-H. and Chang Y.-J., 2002, “Steady-Flow Characteristics and its Influence on Spray for Direct Injection Diesel Engine,”KSME International Journal, Vol.61 No. 7, pp. 86–98.

Dent, J. C., 1971, “A Basis for Comparison of Various Experimental Methods for Studying Spray Penetration,”SAE Paper 710571.

Desantes, J. M., Payri, R., Salvador, F. J. and Gimeno, J., 2003, “Measurements of Spray Momentum for the Study of Cavitation in Diesel Injection Nozzles,”SAE Paper 2003-01-0703.

Flaig, U., Polach, W. and Zieglet, G., 1999, “Common Rail System for Passenger Car DI Diesel Engines ; Experiences with Applications for Series Production Projects,”SAE Paper 1999-01-0191.

Fluent Inc., 2001, “Fluent 6 User’s guide,”.

Ganippa, L. C., Bark, G., Andersson, S. and Chomiak, J., 2001, “Comparison of Cavitation Phenomenon in Transparent Scaled-Up Single-Hole Diesel Nozzles,”Proc. 4th International Symposium on Cavitation, California Institute of Technology, Passadena, CA USA, June 20–23.

Hay, P. and Jones, P. L., 1972, “Comparison of the Various Correlations for Spray Penetration,”SAE Paper 720776.

He, L. and Ruiz, F., 1995, “Effect of Cavitation on Flow and Turbulence in Plain Orifices for High-Speed Atomization,”Atomization and Sprays, Vol. 5, pp. 569–584.

Kampmann, S., Dittus, B., Mattes, P. and Kirner, M., 1996, “The Influence of Hydro-Grinding at VCO Nozzle on the Mixture Preparation in a DI Diesel Engine,”SAE Paper 960867.

Koo, J. Y., 2003, “The Effects of Injector Nozzle Geometry and Operating Pressure Conditions on the Transient Fuel Spray Behavior,”KSME International Journal, Vol. 17, No. 3, pp. 617–625.

Lee, J. H., Cho, S., Lee, S. Y. and Bae, C., 2002, “Development of Cavitation and Enhanced Injector Models for Diesel Fuel Injection System Simulation,” ImechE 2002, Proc Instn Mech Engrs Vol.216, Part D: J Automobile Engineering, pp. 607– 618.

Macián, V., Bermudez, V., Payri, R. and Gimeno, J., 2003, “New Technique for the Determination of the Internal Geometry of Diesel Nozzle with the Use of the Silicone Methodology,”Experimental Techniques, Vol. 27, No. 2, pp. 39–43.

Macián, V., Payri, R., Margot, X. and Salvador, F. J., 2003, “A CFD Analysis of the Influence of Diesel Nozzle Geometry on the Inception of Cavitation,”Atomization and Sprays, Vol. 13, No. 5&6, pp. 579–604.

Nurick, W. H., 1976, “Orifice Cavitation and its Effects on Spray Mixing,”ASME J. Fluids Eng., pp. 681–687.

Ohrn, T. R., Senser, D. W. and Lefebvre, A. H., 1991, “Geometrical Effects on Discharge Coefficients for Plain-Orifice Atomizers,”Atomization and Sprays, Vol. 1, No. 2, pp. 137–153.

Pastor, J. V., Arregle, J. and Palomares, A., 2001, “Diesel Spray Image Segmentation with a Likelihood Ratio test,”Applied Optics, Vol. 40, No. 17, pp. 2876–2885.

Pastor, J. V., Payri, R., Lopez, J. J. and Julia, J. E., 2003, “Effect of Injector Nozzle Geometry of Diesel Engines on the Macroscopic Spray Characteristics by Means of Optical Techniques,” Fuel Injection Systems. ImechE Conference Trans actions. C610/014/2003, pp. 73–82.

Payri, R., Margot, X. and Salvador, F. J., 2002, “A Numerical Study of the Influence of Diesel Nozzle Geometry on the Inner Cavitating flow,”SAE Paper 2002-01-0215.

Pierpont, D. A. and Reitz, R. D., 1995, “Effects of Injection Pressure and Nozzle Geometry on D.I. Diesel Emissions and Performance,”SAE Paper 950604.

Potz, C., Christ, W. and Dittus, E. B., 2000, “Diesel Nozzle the Determining Interface Between Injection System and Combustion Chamber,” Thiesel 2000, Universidad Politecnica de Valencia, ISBN 84-7721-910-9.

Schmidt, D. P. and Corradini, M. L., 1997, “Analytical Prediction of the Exit Flow of Cavitating Orifices,”Atomization and Sprays, Vol. 7, No. 6, pp. 603–616.

Schmidt, D. P., Rutland, C. J. and Corradini, M. L., 1999, “A Fully Compressible Two-Dimensional Model of High Speed Cavitating Nozzles,”Atomization and Sprays, Vol. 9, pp. 255–276.

Siebers, D., 1995, “Scaling Liquid-Phase Penetration in Diesel Based on Mixing-Limited Vaporization,”SAE Paper 950290.

Soteriou, C., Andrews, R. and Smith, M., 1995, “Direct Injection Diesel Sprays and the Effect of Cavitation and Hydraulic Flip on Atomization,”SAE Paper 950080.

Versteeg, H. K. and Malalasekera, W., 1995, “An Introduction to Computational Fluid Dynamics. The finite volume method,” Longman Scientific & Technical.

Wakuri, Y., Fujii, M., Amitani, T. and Tsnumeya, R., 1960, “Studies of the Penetration of a Fuel Spray in a Diesel Engine,”Bull. JSME, Vol. 3, No. 9, pp. 123–130.

Yeom, J.-K., 2003, “A Study on the Behavior Characteristics of Diesel Spray by Using a High Pressure Injection System with Common Rail Apparatus,”KSME International Journal, Vol. 17, No. 9, pp. 1371–1379.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Payri, R., Molina, S., Salvador, F.J. et al. A study of the relation between nozzle geometry, internal flow and sprays characteristics in diesel fuel injection systems. KSME International Journal 18, 1222–1235 (2004). https://doi.org/10.1007/BF02983297

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02983297