Abstract

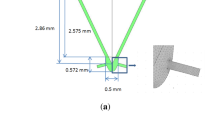

Effects of injector nozzle geometry and operating pressure conditions such as opening pressure, ambient pressure, and injection pressure on the transient fuel spray behavior have been examined by experiments. In order to clarify the effect of internal flow inside nozzle on the external spray, flow details inside model nozzle and real nozzle were also investigated both experimentally and numerically. For the effect of injection pressures, droplet sizes and velocities were obtained at maximum line pressure of 21 MPa and 105 MPa. Droplet sizes produced from the round inlet nozzle were larger than those from the sharp inlet nozzle and the spray angle of the round inlet nozzle was narrower than that from the sharp inlet nozzle. With the increase of opening pressure, spray tip penetration and spray angle were increased at both lower ambient pressure and higher ambient pressure. The velocity and size profiles maintained similarity despite of the substantial change in injection pressure, however, the increased injection pressure produced a higher percentage of droplet that are likely to breakup.

Similar content being viewed by others

References

Chang, S. K. and Koo, J. Y., 1995, “Transient Liquid Breakup Model and Comparison with Phase Doppler Measurements,”KSME Journal, Vol. 9, No. 1, pp. 41–50.

He, L. and Ruiz, F., 1995, “Effects of Cavitation on Flow and Turbulence in Plain Orifices for High-Speed Atomization,”Atomization and Spray, Vol. 5, pp. 569–584.

Koo, J. Y. and Martin. J. K., 1995. “Near Nozzle Characteristics of a Transient Fuel Spray. ”Atomization and Spray, Vol. 5, No. 1, pp. 107–121.

Koo, J. Y., Oh, D. S. and Park, J. H., 1996, “Prediction of the Internal Flow in a Diesel Nozzle,” The 3rd International Symposium on Aerodynamics of Internal Flows, Beijing, pp. 856–862.

Licharowicz, A., Duggins, R. K., Markaland, E., 1965, “Discharge Coefficients for Incompressible Non-Cavitating Flow Through a Long Ori- fice,”Journal of Mech. Engr. Science, Vol. 7. No. 2, pp. 201–219.

Oblander, K., Kollmamm, K., Kramer. M. and Kutschera, I., 1989. “The Influence of High Pressure Injection of Performance and Exhaust Emission of a High Speed Direct Diesel Engine,” SAE Paper 890438.

Ohm, T. R., 1989, “The Effect of Internal Geometry and Injection Pressure on the Flow and Spray Characteristics of a Plain Orifice Atomizer,” M.S, Purdue Univ.

Reitz, R. D. and Bracco, F. B., 1979, “On the Dependence of Spray Angle and Other Spray Parameters on Nozzle Design and Operating Conditions,” SAE paper 790494.

Reitz, R. D. and Diwakar, R., 1986, “Effects of Drop Breakup on Fuel Sparys,” SAE paper 860469.

Ruiz. F., 1981, “A Few Useful Relations for Cavitating Orifices,” ICLASS-91, pp. 595–602.

Shimizu, M., Arai, M. and Hiroyasu, H., 1990, “Disintegrating Progress of a Liquid Jet and Internal Flow in a Nozzle,”JSME, Vol. 56, No.528, pp. 2519–2525.

Wang, X. F., Chin, J. S. and Lefebvre, A. H., 1989, “Influence of Gas-Injector Geometry on Atomization Performance of Aerated-liquid Nozzles,”International Journal of Turbo and Jet Engine. Vol. 6, pp. 271–291.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Koo, J.Y. The effects of injector nozzle geometry and operating pressure conditions on the transient fuel spray behavior. KSME International Journal 17, 617–625 (2003). https://doi.org/10.1007/BF02984463

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02984463