Abstract

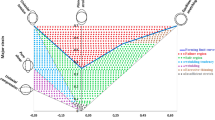

Failure of sandwich sheet materials by tensile instability and localized necking was studied by performing punch-forming experiments on stainless steel clad aluminum. By using narrow blanks and no lubrication, lateral contraction was possible, and failures could be produced in the drawing area of the forming limit diagram. For this deformation regime, diffuse instability led to localized necking. As in monolithic materials, the development of the localized neck in stainless steel clad aluminum determined the forming limit, and predictions of the strain levels for the onset of local instability correlated well with the observed forming limit strains. By preventing lateral contraction, failures in stretching were produced. The forming limit strains in this case depended on the strains at the onset of diffuse instability in much the same manner as is observed for monolithic materials. The strains at the onset of diffuse instability were predicted using a generalized rule of mixtures, and agreement between measured values and values predicted from component properties was good when the strain-path dependence of the instability strain for the individual components was taken into account. The diffuse necking process in stretching of stainless steel clad aluminum led to local thinning when deformations involved small degrees of biaxiallity. On the other hand, nonuniform through thickness straining of the component layers in specimens strained close to balanced biaxial stretching appeared to control the localization process and gave rise to forming limit strains lower than expected from observations of punch formed monolithic sheet materials. For all deformation modes, localized flow culminated in delamination and fracture.

Similar content being viewed by others

References

S. Y. Chung and H. W. Swift:Proc. Inst. Mech. Eng., 1951, vol. 165, p. 199.

R. L. Whitely:Trans. ASM, 1960, vol. 52, p. 154.

W. A. Backofen, W. F. Hosford, Jr. and J. J. Burke:Trans. ASM, 1962, vol. 55, p. 264.

S. P. Keeler:Ductility, ASM, Metais Park, Ohio, 1968.

W. G. Granzow: Armco Fabricating Data Bulletin CF-5, Armeo Steel Corporation, Middletown, Ohio, 1977.

J. D. Jevons:The Metallurgy of Deep Drawing and Pressing, Chapman and Hall, Ltd., London, 1949.

S. S. Hecker:Met. Eng. Quart., 1974, vol. 14, p. 30.

A. K. Ghosh:Met. Eng. Quart., 1975, vol. 15, p. 53.

R. H. Heyer and J. R. Newby:Effects of Mechanical Properties on Biaxial Stretchability of Low Carbon Steels, Paper 680094, SAE Automotive Engineering Congress, Detroit, January, 1968.

J. M. Alexander:Met. Rev., 1960, vol. 5, p. 349.

H. W. Swift:J. Mech. Phys. Solids, 1952, vol. 1, p. 1.

R. Hill:J. Mech. Phys. Solids, 1952, vol. 1, p. 19.

R. Hawkins and J. C. Wright:J. Inst. Metals, 1971, vol. 99, p. 357.

M. Hiraiwa and K. Kondo:Bull. JSME, 1975, vol. 18 p. 442.

F. Negroni, S. Kobayashi, and E. G. Thomsen:Trans. ASME, 1968, vol. 90B, p. 387.

S. P. Keeler and W. A. Backofen:Trans. ASM, 1963, vol. 56, p. 25.

R. D. Venter and M. C. de Malherbe:Sheet. Met. Ind., 1971, vol. 48, p. 656.

A. K. Ghosh and W. A. Backofen:Met. Trans., 1973, vol. 4, p. 1113.

G. M. Goodwin:Application of Strain Analysis to Sheet Metal Forming Problems in the Press Shop, Paper 680093, SAE Automotive Engineering Congress, Detroit, January, 1968.

S. P. Keeler:Circular Grid System—A Valuable Aid for Evaluating Sheet Metal Formability, Paper 680092, SAE Automotive Engineering Congress, Detroit January, 1968.

A. K. Ghosh and S. S. Hecker:Met. Trans., 1974, vol. 5, p. 2161.

Z. Marciniak and K. Kuczynski:Int. J. Mech. Sci., 1967, vol. 9, p. 609.

Z. Marciniak, K. Kuczynski, and T. Pokora:Int. J. Mech. Sci., 1973, vol. 15, p. 789.

M. Azrin and W. A. Backofen:Met. Trans., 1970, vol. 1, p. 2857.

R. Sowerby and J. L. Duncan:Int. J. Mech. Sci., 1971, vol. 13, p. 217.

A. K. Ghosh and S. S. Hecker:Met. Trans. A, 1975, vol. 6A, p. 1065.

S. L. Semiatin and H. R. Piehler:Met. Trans. A, 1979, vol. 10A p. 85.

S. L. Semiatin and H. R. Piehler:Met. Trans. A, 1979, vol. 10A, p. 97.

R. Hill:The Mathematical Theory of Plasticity, Oxford University Press, 1950.

S. L. Semiatin: Ph.D. Thesis. Carnegie-Mellon University, Department of Metallurgy and Materials Science, Pittsburgh, Pa., 1977.

G. G. Moore and J. F. Wallace:J. Inst. Metals, 1964–65, vol. 93, p. 33.

K. Yoshida, K. Yoshii, H. Komorida, M. Usuda, and H. Watanabe:Sci. Papers Inst. Phys. Chem. Res. (Jpn.), 1970, vol. 64, p. 24.

A. S. Korhonen:Sheet Met. Ind., 1978, vol. 55, p. 598.

J. Woodthorpe and R. Pearce:Int. J. Mech. Sci., 1970, vol. 12, p. 341.

M. J. Painter and R. Pearce:J. Phys. D., 1974, vol. 7, p. 992.

A. K. Ghosh:Met. Trans. A, 1976, vol. 7A, p. 523.

A. K. Ghosh:Met. Trans., 1974, vol. 5, p. 1607.

Author information

Authors and Affiliations

Additional information

S. L. SEMIATIN, formerly graduate student, Department of Metallurgy and Materials Science, Carnegie-Mellon University

Rights and permissions

About this article

Cite this article

Semiatin, S.L., Piehler, H.R. Forming limits of sandwich sheet materials. Metall Trans A 10, 1107–1118 (1979). https://doi.org/10.1007/BF02811656

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02811656