Abstract

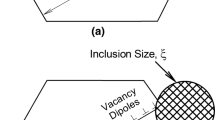

Low cycle fatigue life of nickel-base superalloys is enhanced as a consequence of inclusion reduction in the melt process; however, the functional dependencies between fatigue characteristics and inclusions have not been well investigated. In this study, the propagation mechanism of the fatigue crack initiated from inclusions is examined in fine-grained IN718, which is a representative turbine disc material for jet engines. There is a faceted-striated crack transition on the fracture surfaces. This faceted-striated transition also appears in theda/dN vs crack length curves. It is observed that the faceted crack propagation time can be more than 50 pct of total lifetime in the low cycle fatigue test. The significance of inclusion size effect is explained on the premise that the faceted fatigue crack propagation time scales with the inclusion size, which is taken as the initial crack length. A predictive protocol for determining inclusion size effect is given.

Similar content being viewed by others

References

J.K. Tien and E.A. Schwarzkopf:Electron Beam Melting and Refining-State of the Art 1983, Bakish Materials Corp., Englewood, NJ, 1983, p. 6.

G.E. Maurer:Superalloys, Supercomposites and Superceramics, Academic Press, Inc., San Diego, CA, 1989, p. 84.

P.N. Quested and S. Chakravotry:Electron Beam Melting and Refining-Stateof the Art 1989 Part One, Bakish Materials Corp., 1989, p. 10.

D. Fournier and A. Pineau:Metall. Trans. A, 1977, vol. 8A, pp. 1095–1105.

Y. Murakami:Low Cycle Fatigue, ASTM STP942, 1988, p. 1048.

A. Lasalmonie and J.L. Strudel:J. Mater. Sci., 1986, vol. 21.

C.W. Brown, J.E. King, and M.A. Hicks:Mater. Sci., 1984, vol. 18.

J. Lankford:Int. J. Fract., 1976, vol. 12, p. 155.

C. Laid:Metallurgical Treatises, TMS, Warrendale, PA, 1981, p. 505.

D.D. Krueger, S.D. Antolovich, and R.H. Van Stone:Metall. Trans. A, 1987, vol. 18A, pp. 1431–49.

K.R. Bain, M.L. Gambone, J.M. Hyzak, and M.C. Thomas:Superalloys 1988, TMS, Warrendale, PA, 1988, p. 13.

E.A. Schwarzkopf: Ph.D. Thesis, Columbia University, New York, NY, 1989.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Denda, T., Bretz, P.L. & Tien, J.K. Inclusion size effect on the fatigue crack propagation mechanism and fracture mechanics of a superalloy. Metall Trans A 23, 519–526 (1992). https://doi.org/10.1007/BF02801169

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02801169