Abstract

Micro-mechanical response to overheating events is an important factor when considering the serviceable life of aero-engine components. A key lifing consideration is the low-cycle fatigue (LCF) behavior of nickel-based single-crystal superalloy components. In this study, the LCF response was investigated at different overheating temperatures (1100 to 1300 °C) and times (30 to 120 min). The overheating events had an impact on the γ' phase content, which was observed to decrease with the increase in overheating temperature and time (fully dissolving at 1300 °C). Due to the dissolution of γ' precipitates, the average γ' size was shifted to larger values, however, the subsequent cooling post the overheating events resulted in the formation of tertiary γ' and a bimodal particle distribution. During the LCF tests, that were performed after the overheating exposure, either cyclic hardening or softening was observed. It could be concluded that overheating exposures had no significant effect on the fracture features. However, overheating events resulted in a decrease of LCF properties, which was correlated to the local dislocation response.

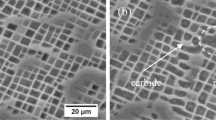

source initiated on the surface oxide layer, (b) the fatigue source initiated on the casting pores in sub surface, (c) secondary cracks initiated on the surface oxide layer, (d) secondary cracks initiated on the internal pores, (e) slip steps, (f) river-like patterns

Similar content being viewed by others

References

R.C. Reed: The Superalloys Fundamentals and Applications, Cambridge University Press, New York, 2008, pp. 90–8.

T.M. Pollock and S. Tin: J. Propul. Power., 2006, vol. 22, pp. 361–74.

J.T. Guo: Materials Science and Engineering for Superalloys: Part A, Science Press, Beijing, 2008, p. 456.

J.B. le Graverend, L. Dirand, A. Jacques, J. Cormier, O. Ferry, T. Schenk, F. Gallerneau, S. Kruch, and J. Mendez: Metall. Mater. Trans. A., 2012, vol. 34, pp. 3946–51.

X.T. Guo, W.W. Zheng, C.B. Xiao, Y.R. Zheng, and Q. Feng: J. Mater. Eng., 2018, vol. 46, pp. 77–86.

R. Giraud, Z. Hervier, J. Cormier, G. Saint Martin, F. Hamon, X. Milhet, and J. Mendez: Metall. Mater. Trans. A., 2013, vol. 44, pp. 131–46.

S.Z. Liu, Z.X. Shi, M. Han, and J.R. Li: Mater. Sci. Forum., 2017, vol. 898, pp. 517–22.

Z.H. Yao, J.X. Dong, M.C. Zhang, and Q.Y. Yu: Trans. Mater. Heat Treat., 2011, vol. 32, pp. 43–49.

J.Y. Tong, K. Yagi, Y.R. Zheng, and Q. Feng: J. Alloys Compd., 2017, vol. 690, pp. 542–52.

J. Cormier: Superalloys 2016: Proceedings of the 13th Intenational Symposium of Superalloys. New Jersey: Wiley, 2016, pp. 385-94.

S. Steuer, Z. Hervier, S. Thabart, C. Castaing, T.M. Pollock, and J. Cormier: Mater. Sci. Eng. A., 2014, vol. 601, pp. 145–52.

R. Giraud, J. Cormier, Z. Hervier, D. Bertheau, K. Harris, J. Wahl, X. Milhet, J. Mendez and A. Organista: Proceedings of the 13th Intenational Symposium of Superalloys, John Wiley & Sons Inc., New Jersey, 2016, pp. 385-394.

K.J. Sun, X.Y. Gai, C.X. Li, and X.P. Song: Part: A Phys Test., 2009, vol. 45, pp. 393–401.

Z.H. Yao, B. Zhou, K.J. Yao, H.Y. Wang, J.X. Dong, and T. Davey: Materials., 2020, vol. 13, pp. 4758–75.

D.A. Kazanskii, A.M. Klypina, and L.D. Chistyakova: Therm. Eng., 2011, vol. 58, pp. 519–25.

Z.X. Shi and S.Z. Liu: Nonferrous Metal Mater. Eng., 2017, vol. 38, pp. 321–25.

H.J. Xie, J.R. Li, M. Han, J. Yu, L. Yang, and X.D. Yue: Rare Metal. Mater. Eng., 2018, vol. 47, pp. 2483–88.

J.B. le Graverend, J. Cormier, F. Gallerneau, S. Kruch, and J. Mendez: Int. J. Fatigue., 2016, vol. 91, pp. 257–63.

A. Baldan: J. Mater. Sci., 2002, vol. 37, pp. 2379–2405.

Y.S. Huang, X.G. Wang, C.Y. Cui, J.G. Li, L.H. Ye, G.C. Hou, Y.H. Yang, J.L. Liu, J.D. Liu, Y.Z. Zhou, and X.F. Sun: Mater. Sci. Eng. A., 2020, vol. 774, p. 138886.

Z.X. Shi, J.R. Li, and S.Z. Liu: Prog. Nat. Sci.: Mater. Int., 2012, vol. 22, pp. 426–32.

J. Yu, J.R. Li, Z.X. Shi, X.G. Wang, S.Z. Liu, and J.Q. Zhao: Rare Metal Mater. Eng., 2013, vol. 42, pp. 1654–58.

A.B. Parsa, P. Wollgramm, H. Buck, A. Kostka, C. Somsen, A. Dlouhy, and G. Eggeler: Acta Mater., 2015, vol. 90, pp. 105–17.

J. Zhang, Y.Y. Guo, M. Zhang, Z.Y. Yang, and Y.S. Luo: Acta Metall. Sin. (Engl. Lett.)., 2020, vol. 33, pp. 1423–32.

K. Kakehi: Met. Mat. Trans. A., 1999, vol. 30A, pp. 1249–59.

S. Suzuki, M. Sakaguchi, and H. Inoue: Mater. Sci. Eng. A., 2018, vol. 724, pp. 559–65.

J.C. Liang, Z. Wang, H.F. Xie, H.J. Shi, and X.D. Li: Int. J. Fatigue., 2019, vol. 128, p. 105195.

J.J. Yu, X.F. Sun, T. Jin, N. Zhao, H.R. Guan, and Z.Q. Hu: Mater. Sci. Eng. A., 2010, vol. 527, pp. 2379–89.

L.M. Bortoluci Ormastronia, L. Mataveli Suave, A. Cervellon, P. Villechaise, and J. Cormier: Int. J. Fatigue., 2020, vol. 130, p. 105247.

R. Jiang, D.J. Bull, A. Evangelou, A. Harte, F. Pierron, I. Sinclair, M. Preuss, X.T. Hu, and P.A.S. Reed: Int. J. Fatigue., 2018, vol. 114, pp. 22–33.

S. Steuer, P. Villechaise, T.M. Pollock, and J. Cormier: Mater. Sci. Eng. A., 2015, vol. 645, pp. 109–15.

H.U. Hong, J.G. Kang, B.G. Choi, I.S. Kim, Y.S. Yoo, and C.Y. Jo: Int. J. Fatigue., 2011, vol. 33, pp. 1592–99.

L.Q. Cui, J.L. Liu, R.L. Peng, J.J. Yu, J. Moverare, and X.F. Sun: Mater. Charact., 2020, vol. 163, p. 110241.

C. He, L. Liu, T.W. Huang, W.C. Yang, J. Zhang, and H.Z. Fu: Mater. Rep., 2019, vol. 33, pp. 2918–28.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 51771017 and No. 52001297).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, M., Zhao, Y., Guo, Y. et al. Effect of Overheating Events on Microstructure and Low-Cycle Fatigue Properties of a Nickel-Based Single-Crystal Superalloy. Metall Mater Trans A 53, 2214–2225 (2022). https://doi.org/10.1007/s11661-022-06663-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06663-9