Abstract

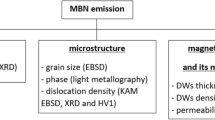

The effects of both volume and surface thermal processing on the parameters of Barkhausen jumps, which are determined by the configuration of a magnetic structure and processes of irreversible displacement of domain boundaries is discussed. Structural changes in steels due to their thermal processing affect the parameters of Barkhausen jumps, which enables utilization of the Barkhausen noise in nondestructive testing of structural states in the steels. Specific examples of applications of this method and instruments for testing the quality of volume and surface thermal processing are given.

Similar content being viewed by others

References

Mikheev, M.N. and Gorkunov, E.S.,Magnitnye metody stukturnogo analiza i nerazrushayushchego kontrolya (Magnetic Methods of Structural Analysis and Nondestructive Testing), Moscow: Nauka, 1993.

Shcherbinin, V.E. and Gorkunov, E.S.,Magnitnyi kontrol’ kachestva metallov (Magnetic Testing of Metal Quality), Ekaterinburg: Ural Division, Russian Academy of Sciences, 1996.

Gorkunov, V.E. and Ul’yanov, A.I.,Magnitnye metody i pribory kontolya kachestva izdelii poroshkovoi metallurgii (Magnetic Techniques and Instruments for Testing Quality of Products of Powder Metallurgy), Ekaterinburg: Ural Division, Russian Academy of Sciences, 1996.

Bhattacharya, D.K., Jayakumar, T., Moorthy, V., Vaidyanathan, S., and Baldev, R., Characterization of Microstructures in 17-4-PH Stainless Steel by Magnetic Barkhausen Noise Analysis,Nondest. Tech. & Eng. Int., 1993, vol. 26, no. 3, pp. 141–148.

Vaidyanathan, S., Moorthy, V., Jayakumar, T., and Baldev, R., Microstructural Characterization of Normalized and Tempered 2.25 Cr-1 Mo Steel Using Magnetic Barkhausen Noise, in:Proceedings of the Eighth Asia-Pacific Conference on Nondestructive Testing (8th APCNDT), Taipei (Taiwan), December 11–14, 1995, pp. 397–404.

Jae-Kyung, Yi., Byong-Whi Lee, and Kim, H.C., Nondestructive Evaluation of Isothermally Annealed 12% CrMoV Steel by Magnetic BN Measurements,J. Magn. & Magn. Mater., 1994, vol. 130, pp. 81–91.

Lavrent’ev, B.V., Magnetic Structure Analyzer Based on Barkhausen Effect for Testing Hardness of Thermally Processed Steel,Defektoskopiya, 1984, no. 3, pp. 79–85.

Wafik, A.H., Razik, N.A., and Zayan, M.H., Barkhausen Jumps and Microstructure in Low-Carbon Steel,Phys. Stat. Sol. (a), 1989, vol. 116, pp. 383–388.

Holler, P., Nondestructive Analysis of Structure and Stresses by Ultrasonic and Micromagnetic Methods, in:Nondestructive Characterization of Materials, Bussiere, J.F.,et al., Eds., New York, London, Plenum, 1987, pp. 211–225.

Veleva, I. and Velev, G., Organization of Nondestructive Magnetic-Noise Testing of Ferromagnetic Materials,Standarti i kachestvo (Bulgaria), 1988, no. 10, pp. 34–36.

Sengupta, A.K. and Theiner, W.A., Nondestructive Evaluation of Stresses in Welds by Micromagnetic Method,Materials Evaluation, 1995, vol. 53, no. 5, pp. 554–558.

Mashkovich, S.B., BS-7 Instrument for Nondestructive Evaluation of Hardness of Ferromagnetic Materials,Tezisy dokl. IV Vsesoyuznoi mezhvuzovskoi konferentsii “Elektromagnitnye metody kontrolya kachestva materialov i izdelii” (Proc. of 4th All-Union Univ. Conf. on Electromagnetic Methods of Quality Control of Materials and Components), Omsk, 1983, pp. 102–103.

Kurzmann, W. and Willman, W., Nondestructive Testing of Structure and Doping through Barkhausen Noise Measurements (Zerstörungsfrele Prüfung auf Gefüge und Legierung durch Messung der Barkhausen-Rauschspannung),Technik, 1970, vol. 25, no. 4, pp. 264–268.

Andrä, W., Magnetic Powder Textures on Martensite,Ann. d. Phys., vol. 15, no. 31. Translated under the titleMagnithye poroshkovye figury na martensite, in:Magnitnaya struktura ferromagnetikov (Magnetic Structure of Ferromagnetics), Vonsovskii, S.V., Ed., Moscow: Inostrannaya Literatura, 1959, pp. 358–361.

Gorkunov, E.S., Dragoshanskii, Yu.N., and Mikhovskii, M., Barkhausen Effect and Its Applications to Structural Analysis of Ferromagnetic Materials (review article II). 2. Effect of Elastic and Plastic Strain,Defektoskopiya, 1999, no. 7, pp. 3–32.

Kameda, J. and Ranjan, R., Nondestructive Evaluation of Steels Using Acoustic and Hardness,Acta Met., 1987, vol. 35, no. 7, pp. 1709–1713.

Tiitto, S., On the Influence of Microstructure on Magnetization Transitions in Steels,Acta Pol. Scand., Appl. Phys. (Helsinki), 1977, no. 119, pp. 3–51.

Gorkunov, E.S., Dragoshanskii, Yu.N., and Mikhovskii, M., Barkhausen Effect and Its Applications to Structural Analysis of Ferromagnetic Materials (Review Article IV). 4. Effect of Carbon and Doping Elements,Defektoskopiya, 1999, no. 12, pp. 3–24.

Gorkunov, E.S., Dragoshanskii, Yu.N., and Rodionova, S.S., Effect of Steel Structure on Cyclic Magnetization Processes in Weak and Strong Magnetic Fields and Solution of Problems of Magnetic Structural Analysis of Products from These Steels,Defektoskopiya, 1998, no. 6, pp. 42–59.

Maussner, G. and Seibold, A., Changes in Magnetic and Mechanical Properties and Microstructure during Annealing of the Stainless Soft Martensitic Steel X5CrNi134(1.4313), inProc. of the 3rd Int. Symp., Saarbrücken (FRG), October 3–6, 1988, pp. 622–635.

Gorkunov, E.S. and Dragoshanskii, Yu.N., Barkhausen Effect and Its Applications to Structural Analysis of Ferromagnetic Materials (review article I). 1. Role of Local Defects and Crystallographic Orientation of Ferromagnets,Defektoskopiya, 1999, no. 6, pp. 3–23.

Vengrinovich, V.L.,Magnitoshumovaya strukturoskopiya (Magnetic-Noise Structural Analysis), Minsk: Navuka i Tekhnika, 1991.

Vengrinovich, V.L., Vishnevsky, A.A., and Tsukerman, V., Ferromagnetic Material Characterization Using Directional Diagrams (DD) of Barkhausen Noise (BN), in:Proc. of 7th European Conf. on NDT, Copenhagen, 1998, vol. 1, pp. 904–911.

Mandal, K., Loukas, M.E., Corey, A., and Athernon, D.L., Magnetic Barkhausen Noise Indications of Stress Concentrations Near Pits of Various Depths,J. Magn. & Magn. Mater., 1997, vol. 175, pp. 225–262.

Vengrinovich, V.L. and Bus’ko, V.N., Barkhausen-Effect Evaluation of Parameters of Surface Layers Case Hardened by Surface Plastic Strain,Defektoskopiya, 1988, no. 10, pp. 56–61.

Lomaev, G.V., Investigations and Evaluation of Ferromagnetic Surface layers Using Barkhausen EffectTezisy dokl. 7-oi Ural’skoi nauchno-tekhnicheskoi konferentsii “Sovremennye metody nerazrushayushchego kontrolya i ikh metrologicheskoe obespechenie” (Abstracts of Papers, 7th Ural Conf. on Contemporary NDT Methods and Measuring Intruments, part 1: Magnetic and Electromagnetic Methods), Ustinov, 1986, pp. 84–86.

Lomaev, G.V., Logunov, S.V., and Logunova, M.G., Selection of Magnetization Regimes for Concurrent Measurements of Thickness and Hardness of Cyanided Layers Using Barkhausen Effect, in:Effekt Barkhausena i analogichnye fizicheskie yavleniya (Barkhausen Effect and Similar Physical Phenomena), Lomaev, G.V., Ed., Izhevsk, Izhev. Gos. Tekh. Univ., 1995, pp. 137–141.

Lomaev, G.V. and Malyshev, V.S., Thickness Measurements and Structural Analysis of Case-Hardened Surfaces of Ferromagnetic Steel Components,Mezhdunarodnaya konferentsiya “Deffektoskopiya-89”, Sbornik dokladov (Proc. of Conf. on Nondesructive Testing-89), Plovdiv (Bulgaria), 1989, vol. 2, pp. 86–90.

Gorkunov, E.S., Magnetic Methods and Instruments for Testing Case-Hardened Surfaces of Ferromagnetic Steel Components,Defektoskopiya, 1991, no. 1, p. 3–23.

Martynenko, Yu.V., Long-Range Effects in Ion Implantation,Itogi nauki i tekhniki (Summary of Science and Technology),Puchki zaryazhennykh chastits i tverdoe telo (Beams of Charged Particles and Solids), 1993, vol. 7, pp. 82–89.

Johnson, E., Structural Phase Transformations in Ion Implanted Nickel and Stainless Steel,Physics Laboratory, University of Copenhagen, 1991–1992, pp. 1–63.

Sokolov, B.K., Gubernatorov, V.V., Dragoshanskii, Yu.N.,et al., Effect of Ion-Beam Processing on Magnetic Properties of Magnetically Soft Materials,Fiz. Met. Metalloved., 2000, vol. 89, no. 4.

Vengrinovich, V.L. and Legotin, S.D., Selective Sensitivity of Barkhausen Noise Method to Properties of Surface Layers,Tezisy dokl. 7-oi Ural’skoi nauchno-tekhnicheskoi konferentsii “Sovremennye metody nerazrushayushchego kontrolya i ikh metrologicheskoe obespechenie” (Abstracts of Papers, 7th Ural Conf. on Contemporary NDT Methods and Measuring Intruments, part 1: Magnetic and Electromagnetic Methods), Ustinov, 1986, pp. 88–89.

Ismagilov, E.M., Numerical Calculations of Parameters of Magnetizing Devices for Testing Based on Measurements of Barkhausen Jumps, in.Effekt Barkhausena i analogichnye fizicheskie yavleniya (Barkhausen Effect and Similar Physical Phenomena), Lomaev, G.V., Ed., Izhevsk, Izhev. Gos. Tekh. Univ., 1995, pp. 116–119.

Tiitto, S. and Säynäjäkangas, S., Spectral Damping in Barkhausen Noise,IEEE Trans. Magn. 1975, vol. 11, no. 6, pp. 1666–1672.

Gorkunov, E.S. and Lapidus, B.M. and Zaiganov, A.V. and Voronov, S.A., and Bushmeleva, G.Ya., Use of Differential Magnetic Permeability in Testing Case-hardened Surfaces,Defektoskopiya, 1988, no. 7, pp. 7–13.

Lomaev, G.V. and Logunova, M.G., Thickness Measurements of Structural Layers by the Barkhausen Effect Method,Defektoskopiya, 1996, no. 11, pp. 10–22.

Höller, P., Nondestructive Analysis of Structure and Stresses by Ultrasonic and Micromagnetic Methods,Nondestructive Characterization of Materials II, Proc. of 2nd Int. Symp., Montreal, July 21–23, 1986, New York, 1987, pp. 211–225.

Theiner, W.A., Kern, R., and Conrad, R., Determination of Surface Integrities by Ferromagnetic Quantities,Proceedings of 1st International Conf. on Surface Engineering, Brighton, England, June 26–28, 1985, paper 25.

Theiner, W.A., Altpeter, I., and Kern, R., Determination of Subsurface ND Techniques,Proc. of Symp. on Nondestructive Characterization of Materials, Montreal, July 21–23, 1986, New York, 1987.

Lomaev, G.V., Method of Magnetic Noise in Nondestructive Testing of Ferromagnets,Defektoskopiya, 1977, no. 4, pp. 75–93.

Lomaev, G.V. and Logunov, S.V., Method of Thickness Measurements of Case-Hardened Layers in Ferromagnetic Materials, Inventor’s Certificate no. 1670372 Al,Byull. Izobr., 1991, no. 30.

Lomaev, G.V. and Ismagilov, E.M., Method of Evolution of Parameters of Components from Ferromagnetic Materials, Inventor’s Certificate no. 1631397 A1,Byull. Izobr., 1991, no. 8.

Sabet-Sharghi, R. and Capham, L., and Atherton, D.L., Characterization of Strain around an Elongated Pit in a Steel Beam under Bending Stress,INSIGHT, 1997, vol. 39, no. 11, pp. 776–779.

Filinov, V.V., Sokolik, A.I., and Shaternikov, V.E., Effect of Surface Plastic Strain in Steel Components on Parameters of Barkhausen Noise,Defektoskopiya, 1986, no. 6, pp. 37–40.

Langmam, R., Some Comparisons between the Measurement of the Stress in Mild Steel by Means of Barkhausen Noise and Rotation of Magnetization,NDT Int., 1987, vol. 20, no. 2, pp. 93–99.

Gardner, C.G., Matzkanin, G.A., and Davidson, D.L., The Influence of Mechanical Stress on Magnetization Processes and Barkhausen Jumps in Ferromagnetic Materials,NDT International-7, 1973, vol. 3, pp. 131–169.

Postgay, G. and Toth, F., Examination of Residual Stresses in Welded Structure Measuring Barkhausen Noise,Mezhdunarodnaya konferentsiya “Deffektoskopiya-89,” Sbornik dokladov (Proc. of Conf. on Nondestructive Testing-89), Plovdiv (Bulgaria), 1980, vol. 2, pp. 110–114.

Postgay, G., Imre, L., and Toth, F., Investigation of a Steel Bridge Element by Measuring Barkhausen Noise,Proc. of 12WC NDT, ed. by J. Boogard and G. M. van Dijk, Amsterdam: Elsevier Sci., 1989.

Postgay, G. and Imre, L., Stress Examination of Bridges Using Barkhausen Noise Measurement,6th European Conf. on NDT, Nice, 1994, pp. 297–302.

Raj, S., Rao, G.B., Bhattacharya, D.K., Raj, B., and Sethi, Y.K, Assessment of Residual Stresses and Post Weld Heat Treatment Butt Weld Joints of 2.25 Cr1Mo Steel Tubes by X-ray Diffraction Technique and Barkhausen Noise Analysis,6th European Conf. on NDT, Nice, 1994, pp. 1239–1240.

Theiner, W.A. and Hauk, V., Nondestructive Characterization of Shot Peened Surface States by the Magnetic Barkhaused Method,Proceedings of 12th World Conf. on NDT, Amsterdam, Elsevier Sci., 1989, pp. 583–587.

Tiitto, K. and Francino, P., Testing Shot Peening Stresses in the Field,The Shot Peener, 1991, vol. 4, pp. 1–2.

Schneider, E., Altpeter, I., and Theiner, W., Nondestructive Determination, of Residual and Applied Stress by Micromagnetic and Ultrasonic Methods, in:Nondestructive Methods for Material Property Determination, Rund, C. O. and Green, R. E., Eds., Plenum, 1984, vol. 4, pp. 115–122.

Karjalainen, I.P. and Moilanen, M., Fatigue Softening and Hardening in Mild Steel Detected from Barkhausen Noise,IEEE Trans. Magn., 1983, vol. 16, no. 3, pp. 514–517.

Grinding, R.J., Burn Detection during Production Using Magnetic Barkhausen Noise Measurements,Material Evaluation, 1987, vol. 45, no. 6, pp. 610–613.

Altpeter, I. and Meyendorf, N., Microscopic Technique for Nondestructive Characterization of Material Structures and Measurement of Local Residual Stresses with High Resolution,6th European Conf. on NDT, Nice, 1994, pp. 531–536.

Kolachevskii,Magnitnye shumy (Magnetic Noises), Moscow: Nauka, 1971.

Vengrinovich, V.L. and Bus’ko, V.N., Magnetic-Noise Technique for Testing Chemical Composition of Ferromagnetic Alloys,Defektoskopiya, 1982, no. 2, pp. 36–44.

Mikhovskii, M. and Bak’’rzhiev, I., and Todorov, T.,Izpolzuvane na shumovoto napryazhenie na Barkhause za izslekovane na chuguni (Using Barkhausen Noise in Investigating Pig Irons), Moscow: Mashinostroenie, 1973, no. 9, pp. 389–391.

Lavrent’ev, B.V., Selection of Cyclic Magnetization Regime in Magnetic Noise Tests of Hardness of Quenched High-Carbon and Case-Hardened Steels,Doklady VIII Vsesoyuznoi nauchno-tekhnicheskoi konferentsii po nerazrushayushchim fizicheskim metodam i sredstvam kontrolya (Proc. of 8th All-Union Conf. on Nondestructive Testing Techniques and Instruments), Kishinev, 1977, part IIa, pp. 256–259.

Willmann, W., Research into Use of Barkhausen Noise in Measuring Techniques (Untersuchungen zur mestechnischen Ausnutzung des magnetischen Barkhausen-effect),Metallkunde, 1969, vol. 136, pp. 3–95.

Tiitto, K.M. and Richard, J., Detection of Heat Treat Defects and Grinding Burns by Measurement of Barkhausen Noise,Nondestruct. Charact. Mater. II, Proc. of 2nd Int. Symp., Montreal, July 21–23, 1986, New York, 1987, pp. 481–489.

Lavrent’ev, B.V., Structural Features of Transducers for Magnetic Structural Analysis Based on Barkhausen Effect,Tezisy dokl. 7-oi Ural’skoi nauchno-tekhnicheskoi konferentsii “Sovremennye metody nerazrushayushchego kontrolya i ikh metrologischeskoe obespechenie” (Abstracts of Papers, 7th Ural Conf. on Contemporary NDT Methods and Measuring Intruments, part 1: Magnetic and Electromagnetic Methods), Ustinov, 1986, pp. 94–95.

Tiitto, K. and Karvonen, I., Evaluating Heat Treat Defects, Grinding Burns, and Stress in Steels by the Barkhausen Noise Method,Nondestructive Testing, Proc. of 4th European Conf., London, September 13–17, 1987, vol. 3, 1988, pp. 1894–1903.

Shakhnin, V.A., Magnetizing Device for Testing Components from Ferromagnetic Materials Using Parameters of Barkhausen Jumps,Defektoskopiya, 1979, no. 9, pp. 102–104.

Lomaev, G.V., Sterkhov, G.V., Ermolaev, V.G., Kolpakov, A.G., and Mikeshkina, G.S., Testing Depth in Cyanided Components from KP08 Steel by the Barkhausen Noise Method,Tezisy dokl. 7-oi Ural’skoi nauchnotekhnicheskoi konferentsii “Sovremennye metody nerazrushayushchego kontrolya i ikh metrologicheskoe, obespechenie” (Abstracts of Papers, 7th Ural Conf. on Contemporary NDT Methods and Measuring Intruments, part 1: Magnetic and Electromagnetic Methods), Ustinov, 1986, p. 108.

Lomaev, G.V., Shtin, A.A., and Malyshev, V.S., SKIF-1 Portable Structure Analyzer Based on Barkhausen Effect,Defektoskopiya, 1986, no. 3, pp. 90–92.

Lomaev, G.V., Mashkovich, S.B., Sitnikov, B.A., and Stepanov, Yu.N., Effect of Grinding Regimes of Tool Steels on Parameters of Barkhausen Jumps,Tezisy dokladov IV Vsesoyuznoi mezhvuzovskoi konferentsii “Elektromagnitnye metody kontrolya kachestva materialov i izdelii” (Abstracts of Papers, 4th All-Union University Conf. on Electromagnetic Methods of Quality Control of Materials and Components), Omsk, 1983, pp. 79–82.

Lomaev, G.V., Malyshev, V.S., and Degterev, A.P., Review of Barkhausen Effect Applications to Nondestructuve Testing,Defektoskopiya, 1984, no. 3, pp. 54–70.

Pustynnikov, V.G., and Vasil’ev, V.M., Effect of Elastic and Plastic Strain in Steel Samples on Spectrum of Magnetic Noise,Defektoskopiya, 1973, no. 5, pp. 126–129.

Sokolik, A.I., New Opportunities for Testing by the Barkhausen Noise Method,Trudy III Vsesoyuznoi shkolyseminara “Effekt Barkhausena i ego ispol’ zovanie v tekhnike” (Proc. of 3rd All-Union School on Barkhausen Noise and Its Applications to Technology), Izhevsk, 1989, pp. 158–159.

Malyshev, V.S., Mashkovich, S.B., and Kosachev, M.A., Testing Parameters of Surface Layers in E1961 steel after Diamond Pressing,Tezisy dokl. 7-oi Ural’ skoi nauchno-tekhnicheskoi konferentsii “Sovremennye metody nerazrushayushchego kontrolya i ikh metrologicheskoe obespechenie” (Abstracts of Papers, 7th Ural Conf. on Contemporary NDT Methods and Measuring Intruments, part 1: Magnetic and Electromagnetic Methods), Ustinov, 1986, pp. 38–39.

Gulyaeva, A.N., Monitoring Technological Regimes of Hardening of Samples from 30KhGSN2A steel by Determining Indirectly the Hardened Layer Thickness,Tezisy dokl. 7-oi Ural’ skoi nauchno-tekhnicheskoi konferentsii “Sovremennye metody nerazrushayushchego kontrolya i ikh metrologicheskoe obespechenie” (Abstracts of Papers, 7th Ural Conf. on Contemporary NDT Methods and Measuring Intruments, part 1: Magnetic and Electromagnetic Methods), Ustinov, 1986, p. 97.

Babenko, V.A., Bus’ko, V.N., Vengrinovich, V.L., Isaikin, N.A., Mironova., A.N., Nikitin, L.A., and Tsukerman, V.L., Barkhausen-Noise Measurements of Parameters of Surface Layers Hardened through Plastic Strain,Tezisy dokladov X Vsesoyuznoi nauchno-tekhicheskoi konferentsii “Nerazrushayushche fizicheskie metody i sredstva kontrolya, Lviv” (Abstracts of Papers, 10th All-Union Conf. on Nondestructive Physical Methods and Testing Instruments, Lviv), Moscow, 1984, book 2, p. 87.

Sokolik, A.I., Pleshakov, V.V., and Lavrent’ev, A.N., Testing Plastically Strained Surface Layers Using Frequency Characteristics of Voltage Pulses due to Barkhausen Jumps,Tezisy dokladov X Vsesoyuznoi nauchno-tekhicheskoi konferentsii “Nerazrushayushchie fizicheskie metody i sredstva kontrolya, Lviv” (Abstracts of Papres, 10th All-Union Conference on Nondestructive Physical Methods and Testing Instruments, Lviv), Moscow, 1984, book 2, p. 108.

Sokolik, A.I., Filinov, V.V., and Lopatin, M.V., Effect of Surface Plastic Strain on Voltage Amplitudes due to Barkhausen Jumps,Tezisy dokladov 5-i nauchno-tekhnicheskoi konferentsii “Sovremennye metody nerazrushayushchego kontrolya i ee metrologischeskoe obespechenie” (Abstracts of Papers, 5th Conf. on Contemporary Techniques of Nondestructive Testing and Required Instruments), Izhevsk, 1984, pp. 95–97.

Zverev, V.A., Kreisik, I.P. Kreisik, T.A., Mel’nikova, V.F., and Pushkina, E.L., Design of a Magnetic Noise Structural Analyzer for Assessing Physicomechanical States of Surface Layers of Ferromagnetic Components,Tezisy dokladov nauchno-tekhnicheskogo soveshchaniya “Effekt Barkhausena i ego ispol’ zovanie v tekhnike” (Abstracts of Papers, Conf. on Barkhausen Noise and Its Application to Technology), Izhevsk, 1977, pp. 148–150.

Heifetz, G.S., Analytical Determination of the Depth of a Hardened Layer Obtained by Surface Rolling of Steel Components,Trudy of Central Sci.-Research Inst. of Heavy Machine Building, vol. 49, Moscow, 1952.

Batler, M.A.,Uprochnenie detalei mashin (Strengthening Machine Components), Moscow: Mashinostroenie, 1968.

Vasil’ev, V.M., and Popova, V.V., Effect of Plastic Strain in Ferromagnets on Distributions of Domain Dimensions,Tezisy dokladov II Vsesoyuznoi mezhvuzovskoi konferentsii po elektromagnitnym metodam kontrolya (Abstracts of Papers, 2nd All-Union Conf. on Electromagnetic Testing Techniques), part 2, Riga, 1975, pp. 149–155.

Dragoshanskii, Yu.N. and Sokolov, B.K., Control over Domain Structure as a Means of Optimizing Magnetic Properties of Laser-Treated Anisotropic Electrotechnical Steels,Izv. Akad. Nauk SSSR, 1989, vol. 53, no. 4, pp. 610–613.

Sokolov, B.K., Dragoshanskii, Yu.N., Gubernatorov, V.V.,et al., Improving Magnetic Properties of Laser-Treated Anisotropic Electrotechnical Steel,Fiz. Met. Metalloved., 1989, vol. 68, no. 3, pp. 570–577.

Sokolov, B.K. and Dragoshanskii, Yu.N., Magnetostructural Barriers and Reduction in Magnetic Losses in Anisotropic Electrotechnical Steels,Fiz. Met. Metalloved., 1991, no. 1, pp. 92–102.

Dragoshanskii, Yu.N., Sokolov, B.K., Gubernatorov, V.V.,et al., Effect of Local Laser Treatment on Magnetic Losses in Amorphous Electrotechnical Alloys,Fiz. Met. Metalloved, 1993, vol. 75, no. 1, pp. 64–70.

Sokolov, B.K., Gubernatorov, V.V., Dragoshanskii, Yu.N.,et al., Local Laser Treatment of a Thinnest Strip of Electrotechnical Steel,Fiz. Met. Metalloved., 1993, vol. 75, no. 5, pp. 36–42.

Dragoshanskii, Yu.N., Shulika, V.V., and Potapov, A.P., New Technique of Optimization of Magnetic Anisotropy in Electrotechnical Strips,Stal’, 1996., no. 3, pp. 58–61.

Dragoshanskii, Yu.N., Zaikova, V.A., and Khan, E.B., Relation between Electromagnetic Losses in Single Crystals of Silicon-Doped Iron and Crystallographic Orientation of Their Surfaces,Fiz. Met. Metalloved., 1972, vol. 34, issue 1, pp. 987–994.

Dragoshanskii, Yu.N., Physical Mechanisms of Dynamic Fragmentation of Domain Structure of Electrotechnical Materials. 1. Dynamics of Domain Boundaries,Fiz. Met. Metalloved., 1994, vol. 77, no. 1, pp. 95–105.

Sokolov, B.K., Gubernatorov, V.V., Chistyakov, V.K., et al.,Lazernaya obrabotka elektrotekhnicheskoi stali v uprugo-rastyanutom sostoyanii (Laser Treatment of Transformer Steel in Elastically Strained State). Available from VINITI, 1989, Moscow, no. 32792, pp. 1–34.

Lazernaya tekhnika i tekhnologiya (Lasers and Laser Technologies, in 7 volumes), Grigo’yants, A. G., Ed., Moscow: Vysshaya Shkola, 1987, vol. 3.

Kraposhin, V.S., Thermal Processing of Steels and Alloys Using Laser Beams and Other Advanced Heating Techniques,Itogi nauki i tekhniki (Summary of Science and Technology), vol. 21: Physical Metallury and Thermal Processing, Moscow: VINITI, 1987, pp. 144–206.

Industrial Applications of Lasers, Koebner, H., Ed., New York: John Wiley & Sons, 1984. Translated under the titlePromyshlennoe primenenie lazerov, Moscow Mashinostroenie, 1988.

Ready, J.,Industrial Applications of Lasers, New York, San Francisco, London: Academic, 1978. Translated under the titlePromyshlennoe primenenie lazerov, Moscow: Mir, 1981.

Kolpakov, A.G., Kutanov, M.Yu., Popova, N.I., Sittsevaya, E.Yu., and Guiva, V.A., Nondestructive Monitoring of Laser Thermal Processing of Tubes for Engines,Trudy III Vsesoyuznoi shkoly-seminara “Effekt Barkhausena i ego ispol’zovanie v tekhnike” (Proc. of 3rd All-Union School on Barkhusen Noise and Its Applications to Technology), Izhevsk, 1989, pp. 129–132.

Vengrinovich, V.L., Feasibility of Nondestructive Determination of Thicknesses of Structural Zones and Hardness of Laser-Hardened Layers,Abstracts of All-Union Conf. on Laser Applications to Machine-Building Technologies. Moscow: Nauka, 1982, pp. 85–86.

Vengrinovich, V.L., Astapchik, S.V., and Babushkin, V.B., Nondestructive Testing of Structural Zones of Laser Quenching,Fizika i Khimiya Obrabotki, Materialov, 1984, no. 6, pp. 10–16.

Vengrinovich, V.L., Yakunin, V.P., Legotin, S.D., and Bus’ko, V.N., Measuring Parameters of Laser-Hardened Layers in Ferromagnetic Materials Using Barkhausen Noise,Defektoskopiya, 1986, no. 2, pp. 87–89.

Vengrinovich, V.L., Yakunin, V.P., Legotin, S.D., and Bus’ko, V.N., On Thickness of Informative Layer in Magnetic-Noise Structural Analysis,Defektoskopiya, 1986, no. 2, pp. 89–93.

Malyshev, V.S., Mashkovich, S.B., Lomaev, G.V., Goryuchkin., A.I., and Kutanov, Yu.I., Monitoring Pulsed Laser Quenching of 30KhRA Steel Using Barkhausen Noise,Defektoskopiya, 1986, no. 12, pp. 70–74.

Lomaev, G.V., Suntsova, N.D., Nemets, A.M., and Gorbunova, N.V., Monitoring Laser Quenching Using Barkhausen Noise, in:Effekt Barkhausena i analogichnye fizicheskie yavleniya (Barkhausen Effect and Similar Physical Phenomena), Lomaev, G.V., Ed., Izhevsk, Izhev. Gos. Tekh. Univ., 1995, pp. 143–148.

Poludnitsyn, A.N., Orlov, S.Yu., and Degterev, A.P., Applications of Barkhausen Noise to Monitoring Laser Quenching,Trudy III Vsesoyuznoi shkoly-seminara “Effekt Barkhausena i ego ispol’ zovanie v tekhnike” (Proc. of 3rd All-Union School on Barkhausen Noise and Its Applications to Technology), Izhevsk, 1989, p. 133.

Legotin, S.D.,Kontrol’ lokal’no zakalennykh sloev metodom effekta Barkhausena (Testing Locally Quenches Layers Using Barkhausen Noise), Minsk, 1990.

Kern, R., Meyer, R., Theiner, W.A., and Valeike, B., Process Integrated Nondestructive Testing of Laser-Hardened Components,Proc. of 7th Int. Symp. on the Nondestructive Characterization of Materials, Prague, June 1995.

Filinov, V.V. and Merzlyakov, Yu.M., On Characterization of Conducting Coatings Using Barkhausen Noise, in:Effekt Barkhausena i analogichnye fizicheskie yavleniya (Barkhausen Effect and Similar Physical Phenomena), Lomaev, G.V., Ed.., Izhevsk, Izh. Gos. Tekh. Univ., 1995, pp. 165–171.

Mikhovskii, M., Zakhova, A., and Yanev, B., About Another Possibility of Improving the Accuracy of Ultrasonic Flaw Detection in the Presence of Corrosion Damage,Natsional’naya konferentsiya Defektoskopiya-95 (Proc. of National Conf. on Nondestructive Testing-95), Sozopol (Bulgaria), 1995, pp. 141–146.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gorkunov, E.S., Dragoshanskii, Y.N. & Mikhovski, M. Barkhausen noise and its utilization in structural analysis of ferromagnetic materials (Review article V) 5. Effects of volume and surface thermal processing. Russ J Nondestruct Test 36, 389–417 (2000). https://doi.org/10.1007/BF02759376

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02759376